Axle center self-regulation and vibration reduction bearing block

A bearing seat and shaft center technology, which is applied in the field of mechanical parts, can solve the problems of reducing the service life of transmission parts, the concentricity error of bearing installation holes, and the vibration of transmission parts, etc., so as to reduce vibration, increase service life, reduce abnormal Effects of normal wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

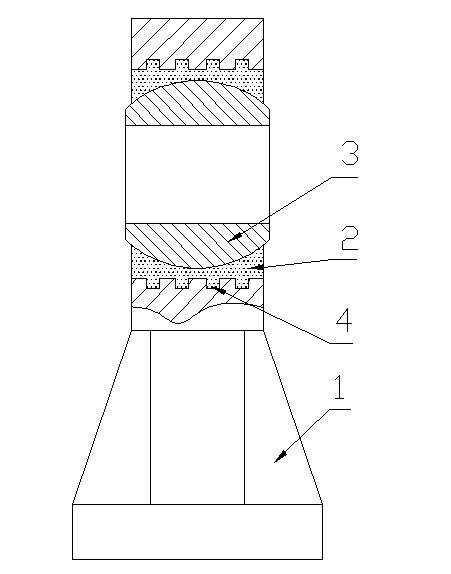

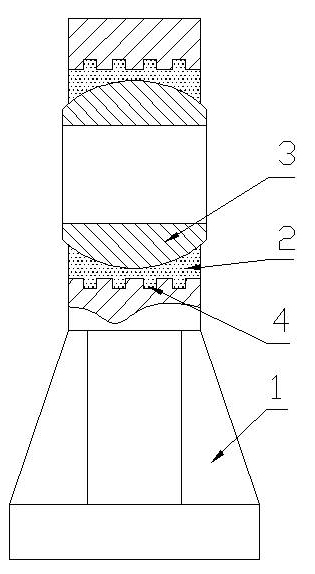

[0008] The self-adjusting shaft center and vibration-damping bearing seat includes a fixed support seat 1, a liner 2, and a bearing seat 3, and an annular groove 4 is arranged in the shaft hole of the fixed support seat 1. There is a bearing seat on the central axis of the shaft hole. The shape of the bearing seat 3 is spherical. There is a certain space between the outer spherical surface of the bearing seat 3 and the inner circular surface of the shaft hole of the fixed support seat 1. A liner 2 is provided in the space between the shaft holes of the fixed support seat 1, and the liner 2 is 10-20 parts by weight of polytetrafluoroethylene powder, 25-35 parts of glass fiber, and 50-20 parts of nylon. 60 parts of raw materials are mixed, granulated, heated, and directly injected into the space between the shaft hole of the fixed support seat and the outer spherical surface of the bearing seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com