Continuous variable valve timing adjusting system for internal combustion engine

A valve timing and adjustment system technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of difficult reliability, complex structure, and many driven parts, so as to improve economy, power, High adjustment accuracy and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

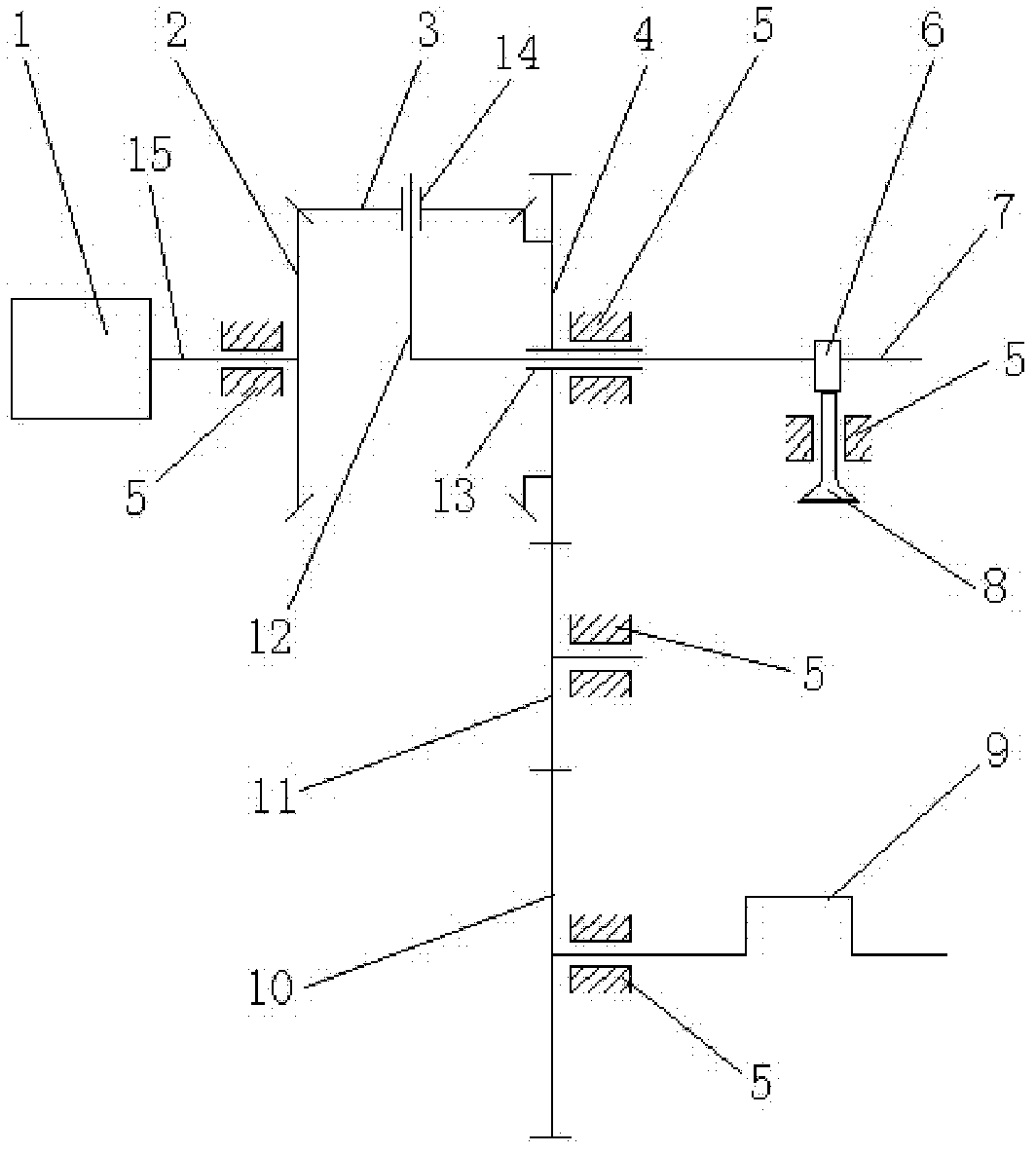

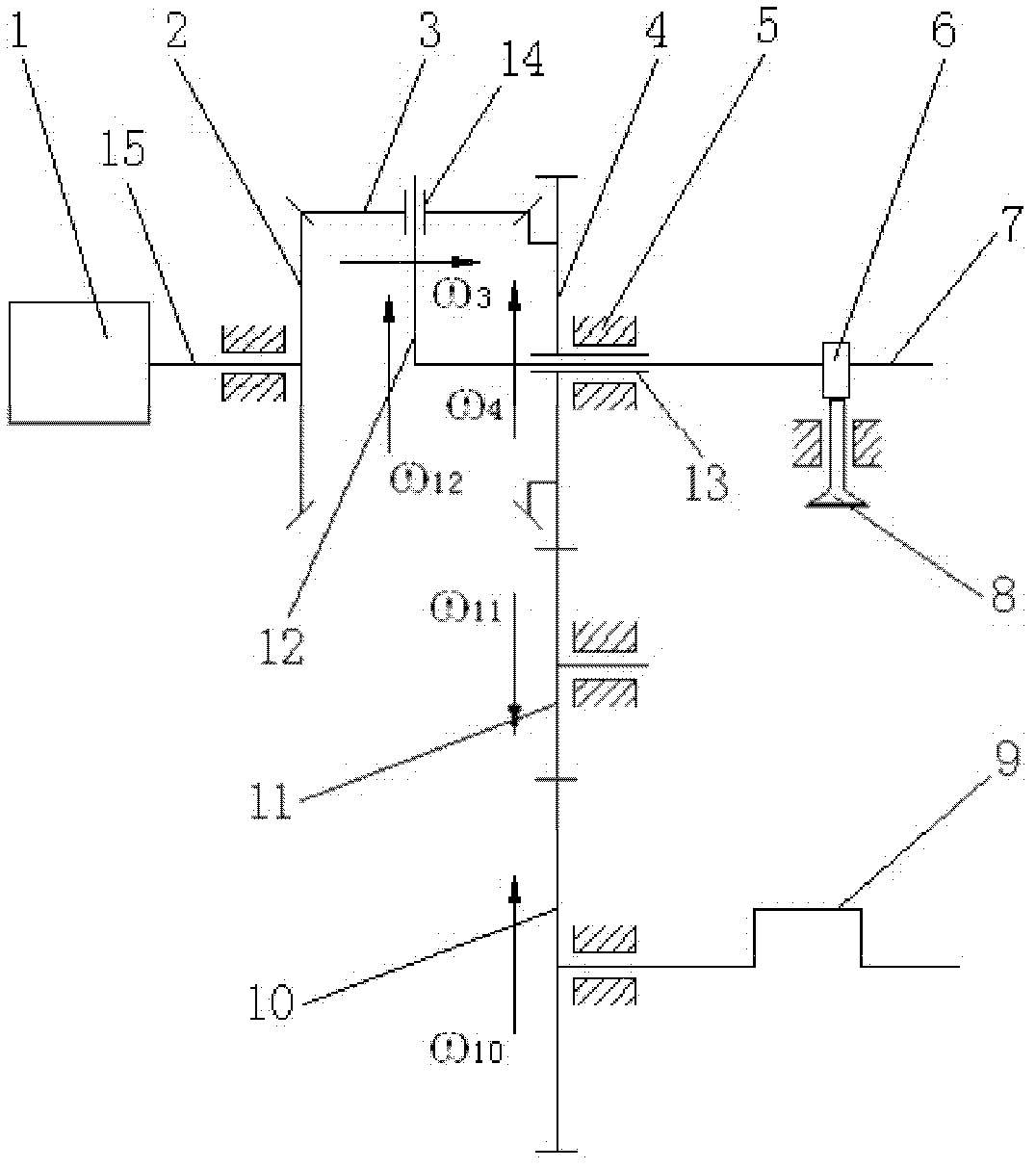

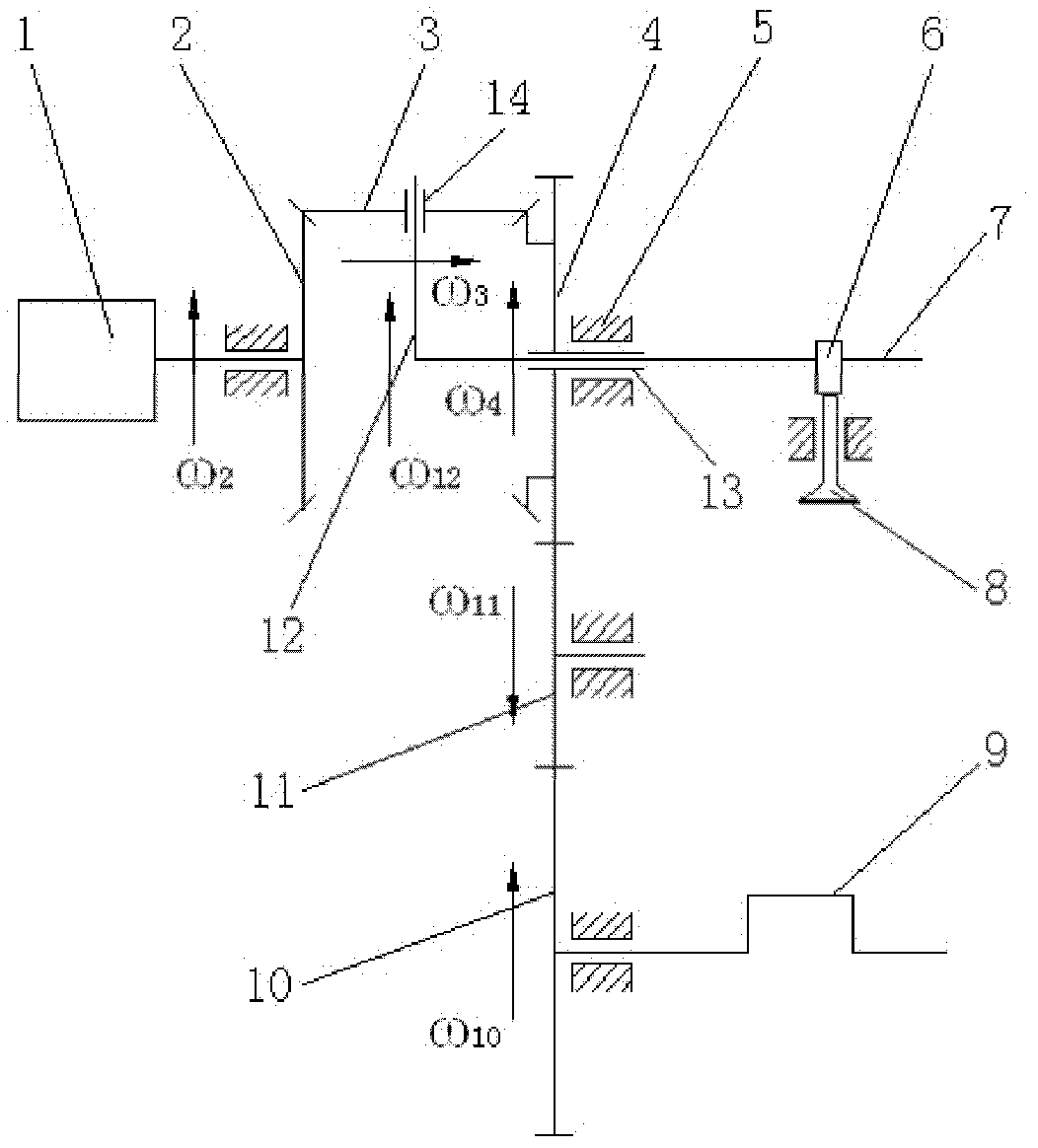

[0018] Such as figure 1 As shown, the present invention includes: internal combustion engine body 5, crankshaft 9, camshaft 7, cam 6, valve 8, drive gear 10, intermediate transmission 11, input sun gear 4, differential gear 3, differential gear carrier 12, adjustment Central gear 2, adjustment device 1, input sun gear casing 13, differential gear casing 14 and connecting shaft 15, camshaft 7 passes through the axis of cam 6 and is connected with cam 6 as a whole, the valve stem of valve 8 and The cams 6 are in contact, the input sun gear sleeve 13 is installed on the axis of the input sun gear 4, the differential gear sleeve 14 is installed on the axis of the differential gear 3, and the front end of the crankshaft 9 is installed on the axis of the drive gear 10. At the center, the ring gear of the input sun gear 4 includes an outer ring gear and an inner bevel gear, the intermediate transmission device 11 meshes with the drive gear 10 and the outer ring gear of the input sun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com