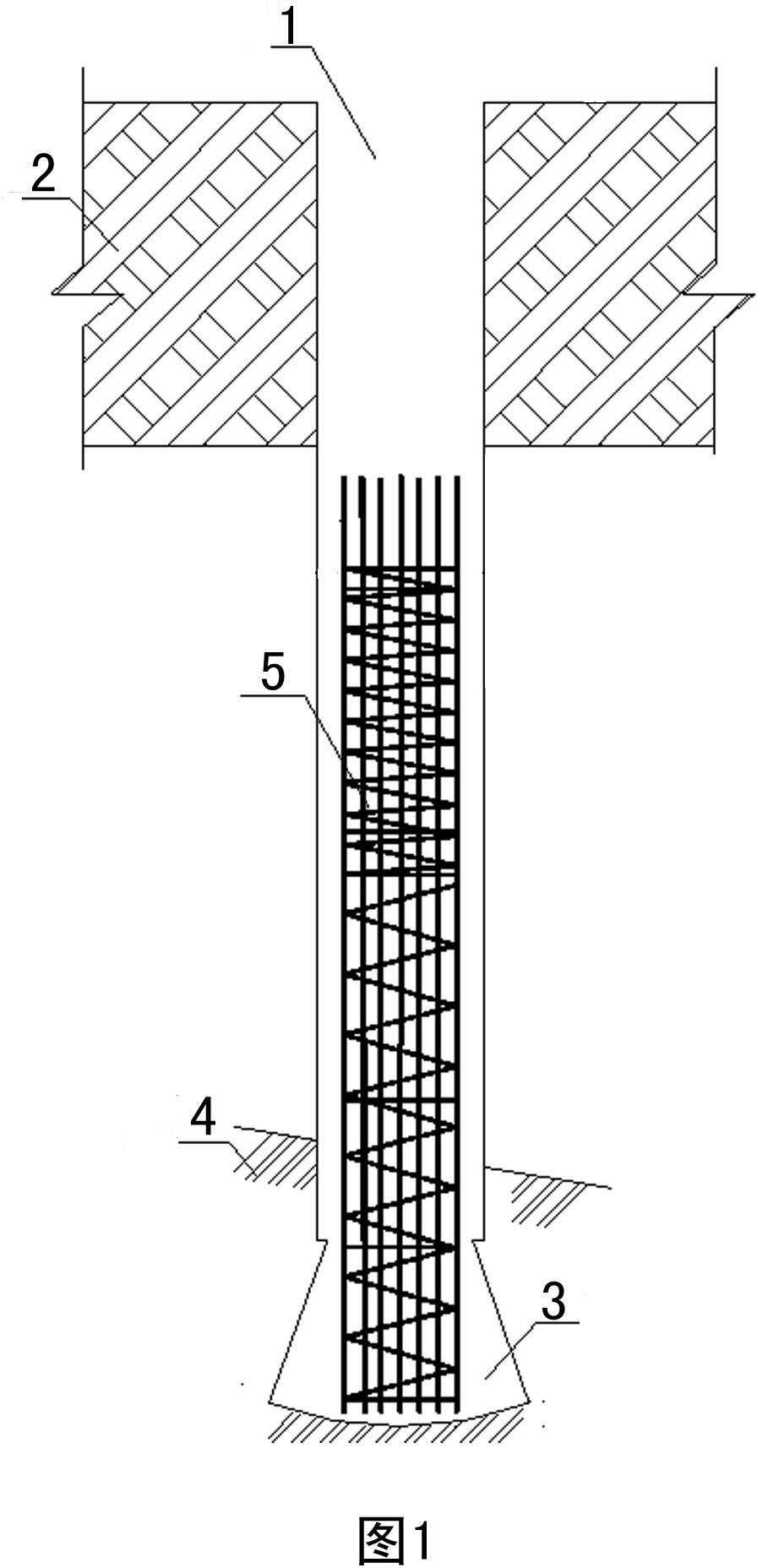

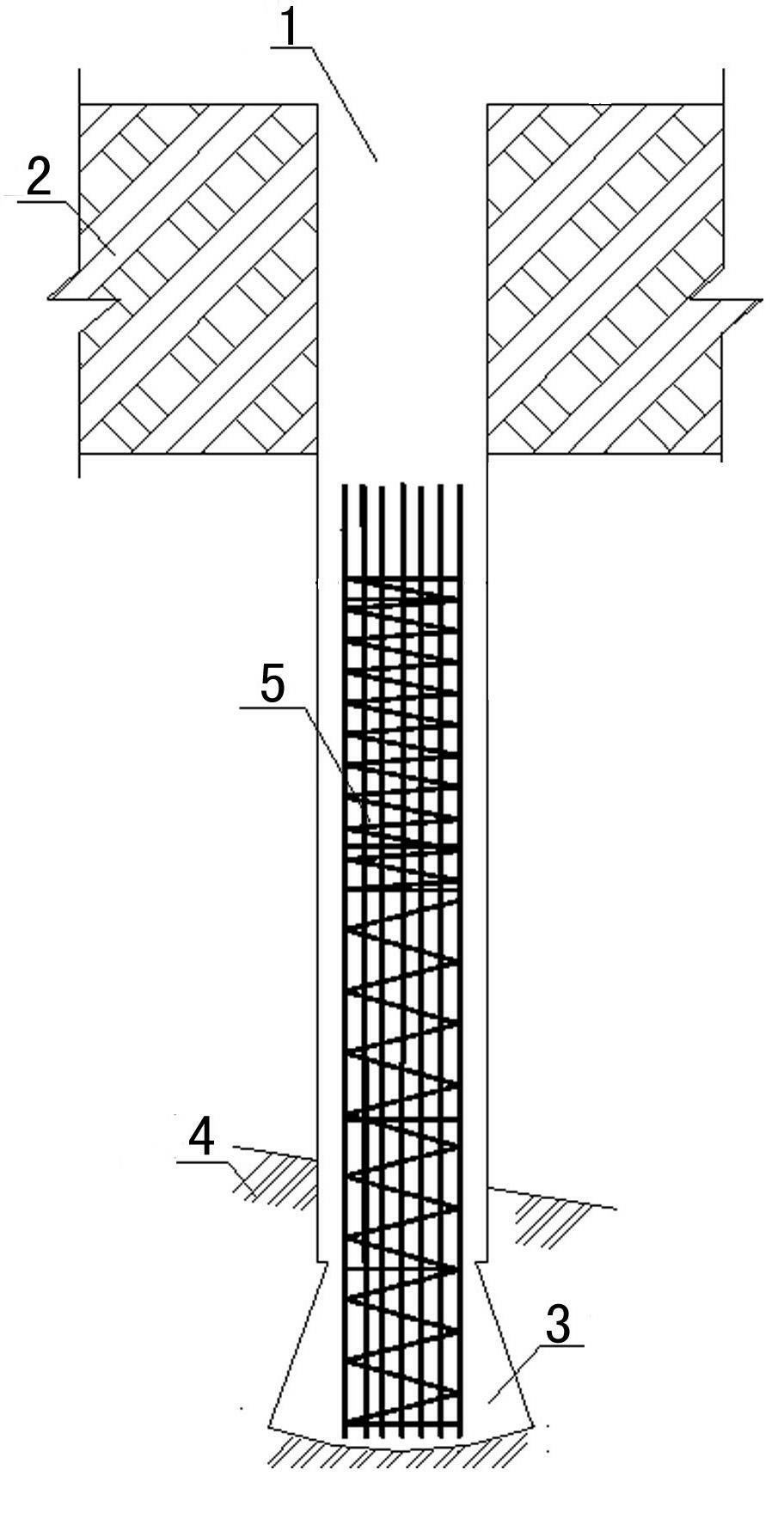

Method for constructing engineering pile by combining rotary drilling rig with manual pile base chambering

A technology of rotary drilling rig and construction method, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as poor mechanical bottom expansion effect, low degree of mechanization, and unsatisfactory hole-forming quality

- Summary

- Abstract

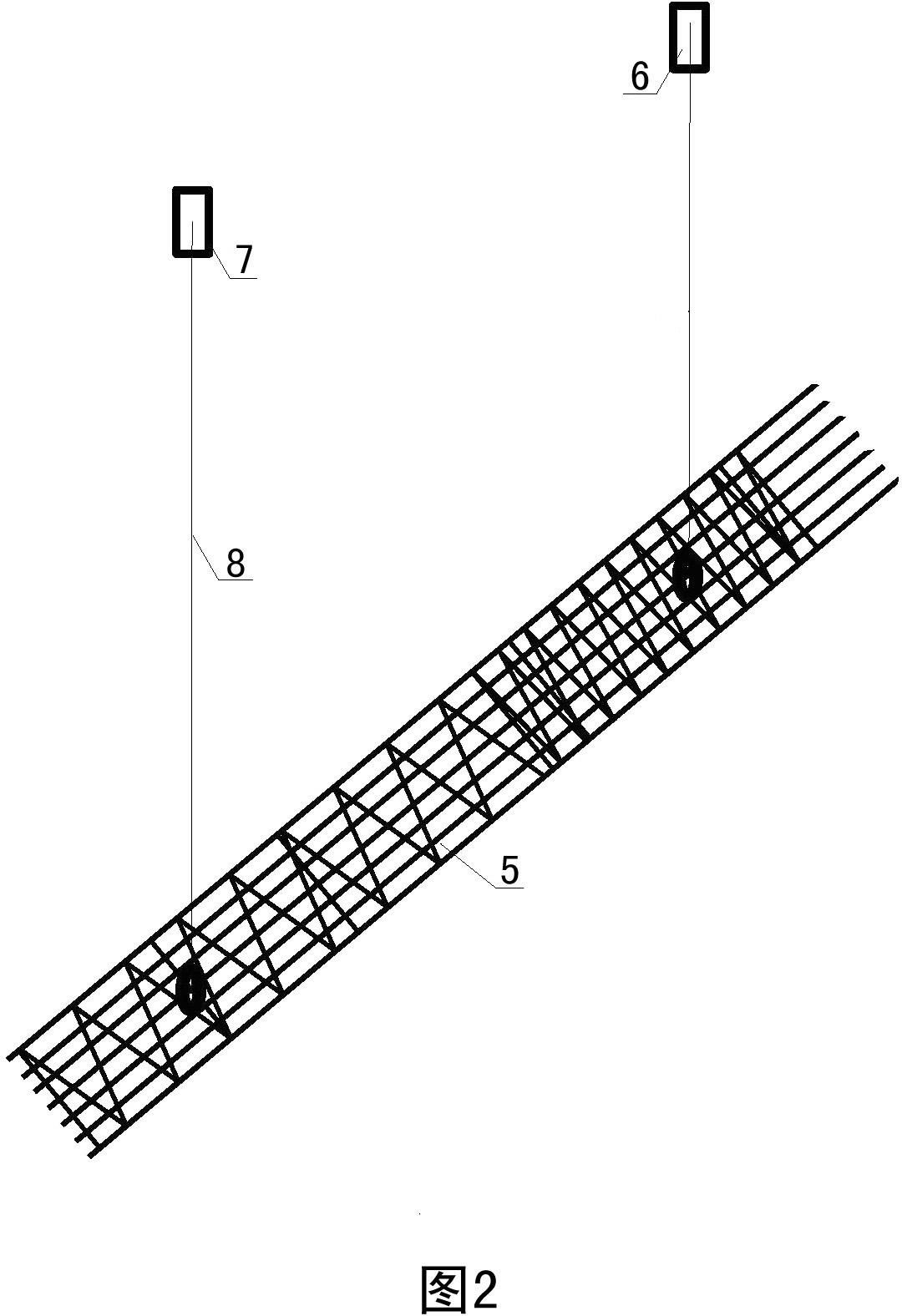

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific implementation case, concrete construction method of the present invention is described in detail as follows:

[0040] 1. Geological survey

[0041]Before construction, it is necessary to understand the geological conditions of the construction area according to the geotechnical engineering investigation data. For example: the strata from top to bottom of this project are roughly distributed as follows: 1 miscellaneous fill, 1-2 plain fill; 2 muddy silty clay; 3 silty clay; 4 silt; 5 round gravel; 5-1 silty Clay; 6 silty clay; 7 strongly weathered argillaceous siltstone; 8 moderately weathered argillaceous siltstone; 9 strongly weathered conglomerate; 10 moderately weathered conglomerate.

[0042] 2. Construction preparation

[0043] 1. Machinery and equipment

[0044] List of machinery and equipment to be put into use

[0045] serial number Machinery or equipment name Model Specifications quantity Remark 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com