Waterproof crack-resistant inorganic heat-insulating mortar and preparation method thereof

A technology of inorganic thermal insulation mortar and ceramic sand, applied in the field of building thermal insulation, can solve the problems of easy cracking and high water absorption, and achieve the effects of reducing water absorption, increasing strength, good workability and constructability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

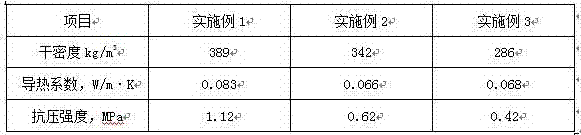

Examples

Embodiment 1

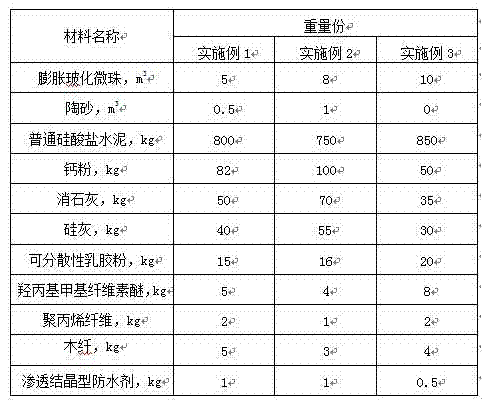

[0032] The components and parts by weight of Examples 1-3 are shown in Table 1. Wherein, the viscosity of hydroxypropyl methylcellulose ether in embodiment 1 is 40000mPa·S, and the bulk density of expanded vitrified microspheres is 90kg / m 3 The particle diameter of described pottery sand is 5mm, and the grade of ordinary portland cement is 42.5; The viscosity of hydroxypropyl methyl cellulose ether is 70000mPa·S among the embodiment 2, and the bulk density of expanded vitrified microbead is 100kg / m 3 The particle diameter of described pottery sand is 3mm, and the grade of ordinary portland cement is 42.5; The viscosity of hydroxypropyl methyl cellulose ether is 100000mPa·S among the embodiment 3, and the bulk density of expanded vitrified microbead is 110kg / m 3 ; The particle size of the pottery sand is 1mm, and the grade of ordinary Portland cement is 52.5.

[0033] Table 1

[0034]

[0035] The ordinary Portland cement, silica fume, slaked lime, hydroxypropyl methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com