Method for controlling cementation of casting roller on fan-shaped section of continuous casting machine

A continuous casting machine segment and control method technology, applied in the field of reducing the occurrence rate of continuous casting roll surface sticking, to achieve the effect of reducing cleaning frequency, reducing enrichment and sticking, and improving casting machine operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

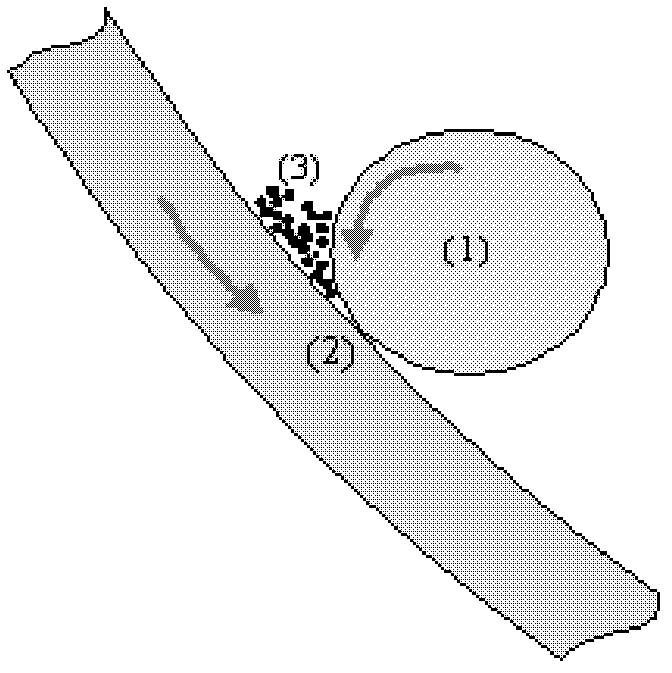

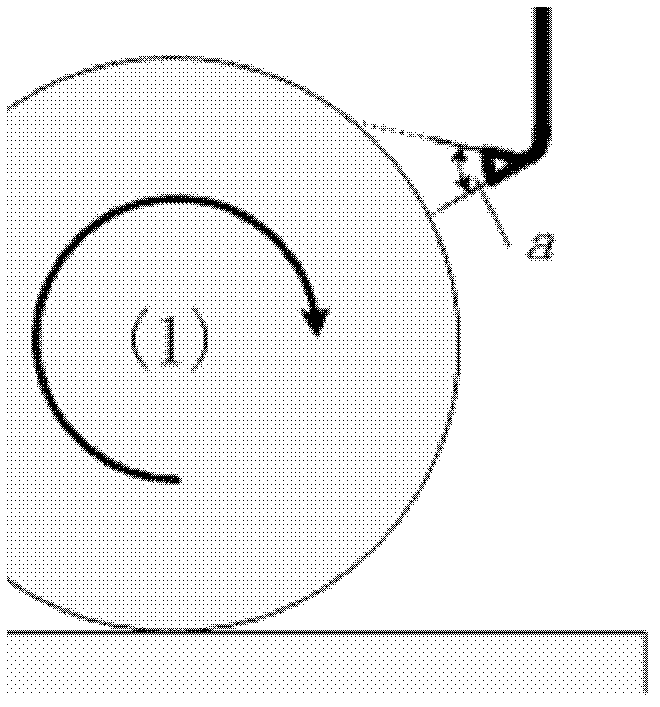

[0028] Continuous casting machine equipment parameters: curved slab continuous casting machine, the production continuous casting slab section width specifications are 1600mm, 1800mm, 2100mm, and the thickness direction specifications are 180mm, 200mm, 250mm. The streamline length is 35.5m, the continuous casting roll radius is 230mm (arc section) and 300mm (straightening section and horizontal section), and it is divided into 8 secondary cooling zones.

[0029] Concrete parameters in the implementation of the present invention are: nozzle spray angle width to spray angle 60 °, nozzle installation position 25mm away from slab edge, 180mm (arc section) and 250mm (straightening section and horizontal section) apart from slab surface vertical distance . Air mist nozzles are installed near each inner arc roller in the 5th-8th segment of the continuous casting machine. The average cooling water flow of each nozzle is 0.15l / min.

[0030] Before the application of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com