Discharge port quick switching device used in cold drink production

A technology of rapid switching and discharge nozzle, applied in the fields of frozen desserts, food science, application, etc., can solve the problems of reduced product yield, unable to meet market demand, complex discharge nozzle structure, etc., to improve productivity, improve The effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

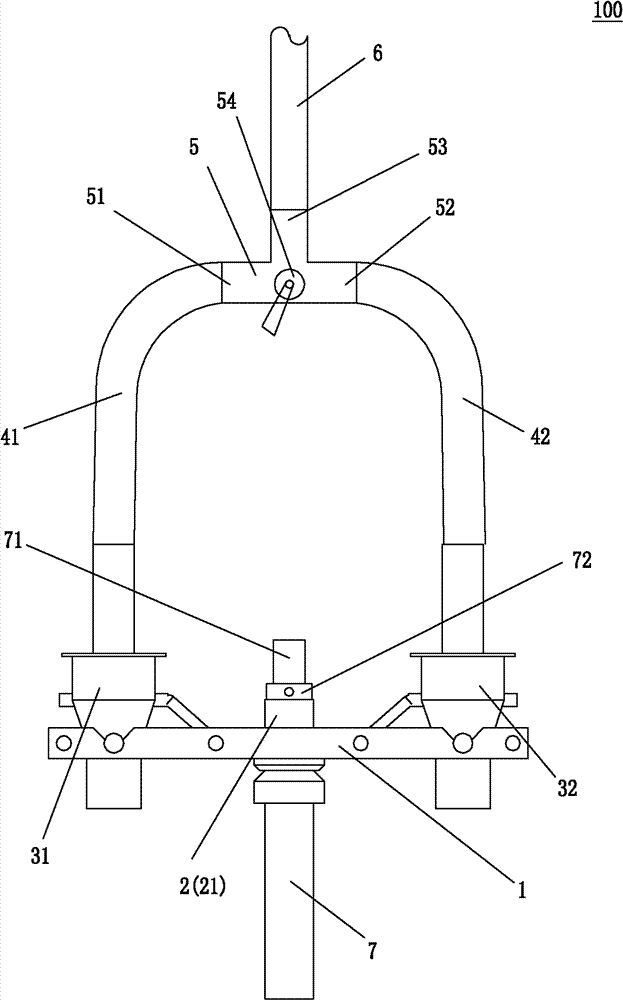

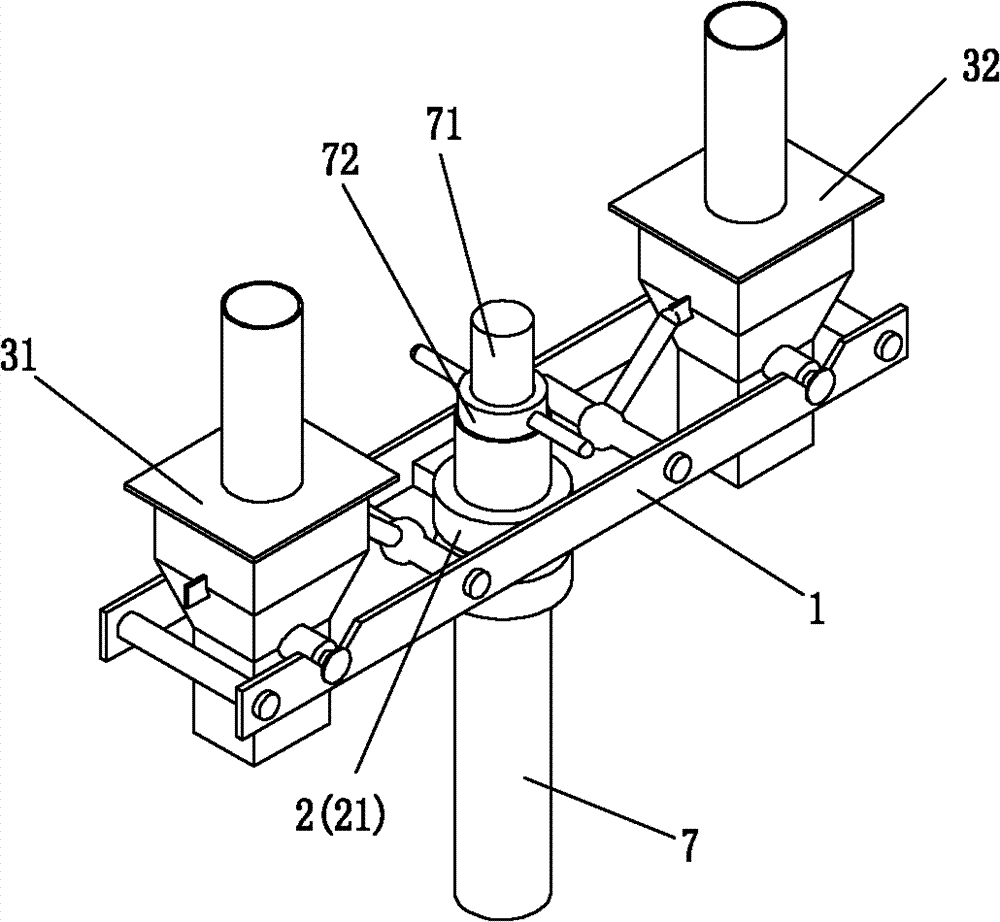

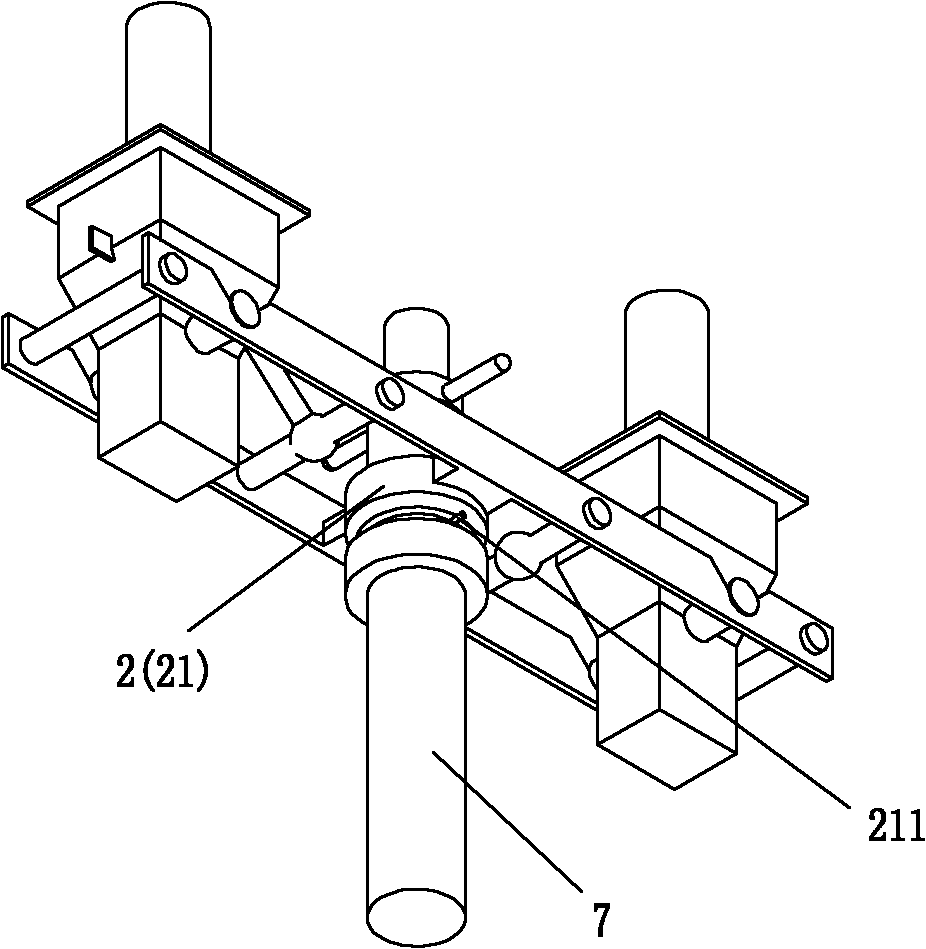

[0023] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a quick switch device 100 for the discharge nozzle in the production of cold drinks. The quick switch device 100 includes a horizontally arranged nozzle frame 1. Both ends of the mouth frame 1 and symmetrical to the rotating connection part 2 are respectively provided with a first discharge nozzle 31 and a second discharge nozzle 32; 41,42 are connected to the two outlet ports 51,52 of the three-way valve 5, the inlet port 53 of the three-way valve 5 communicates with a main feed pipe 6, the inlet port 53 of the three-way valve is connected to the two outlet ports The conduction of 51 and 52 is controlled by a ball valve 54 ; the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com