10KV line insulation lightning arrester and lightning shielding method

A line insulation and lightning rod technology, which is applied to the installation of electrical components, cables, lighting conductors, etc., can solve problems such as difficulty in withstanding direct lightning or induction lightning, insufficient lightning resistance level of insulated lines, and burning of porcelain insulator sheds, etc. , to avoid lightning strikes, avoid line disconnection and tripping accidents, and avoid water ingress and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

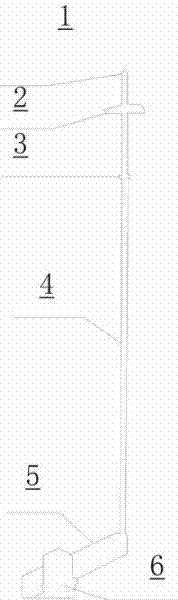

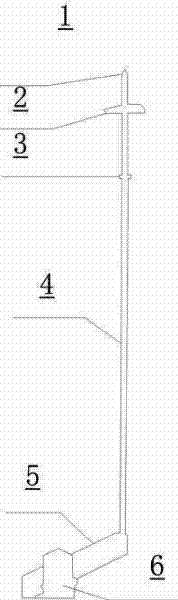

[0020] Such as figure 1 Shown: a 10KV line insulation lightning rod, including: lightning terminal 1, lightning equalizing ring 2, L-shaped insulating structure, ground connection fixture 6, the vertical upper end of the L-shaped insulating structure is connected to the grounding terminal through a snap ring 3 The lightning equalizing ring 2 is connected, and the upper end of the lightning equalizing ring 2 is fixedly connected to the lightning pin 1; the horizontal end of the L-shaped insulating structure is connected to the grounding wire on the line pole through the grounding connection fixture 6 .

[0021] The L-shaped insulating structure is formed by connecting vertical insulating sleeves 4 and horizontal insulating cross arms 5 . The insulating sleeve is composed of a round steel and an insulating rubber tube sleeved on the round steel; the round steel is a round steel with a diameter of 12mm, the length of the round steel is 1m-1.5m, and the square value of the cross s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com