Stirling engine with eccentric shaft rolling rotation ring

A Stirling engine and eccentric shaft technology, applied in the direction of machines/engines, hot gas variable displacement engine devices, mechanical equipment, etc., can solve the problems of large system volume, heavy mass, and affecting the market application and promotion of external combustion engines , to achieve the effect of simple system structure, low cost and excellent heat transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

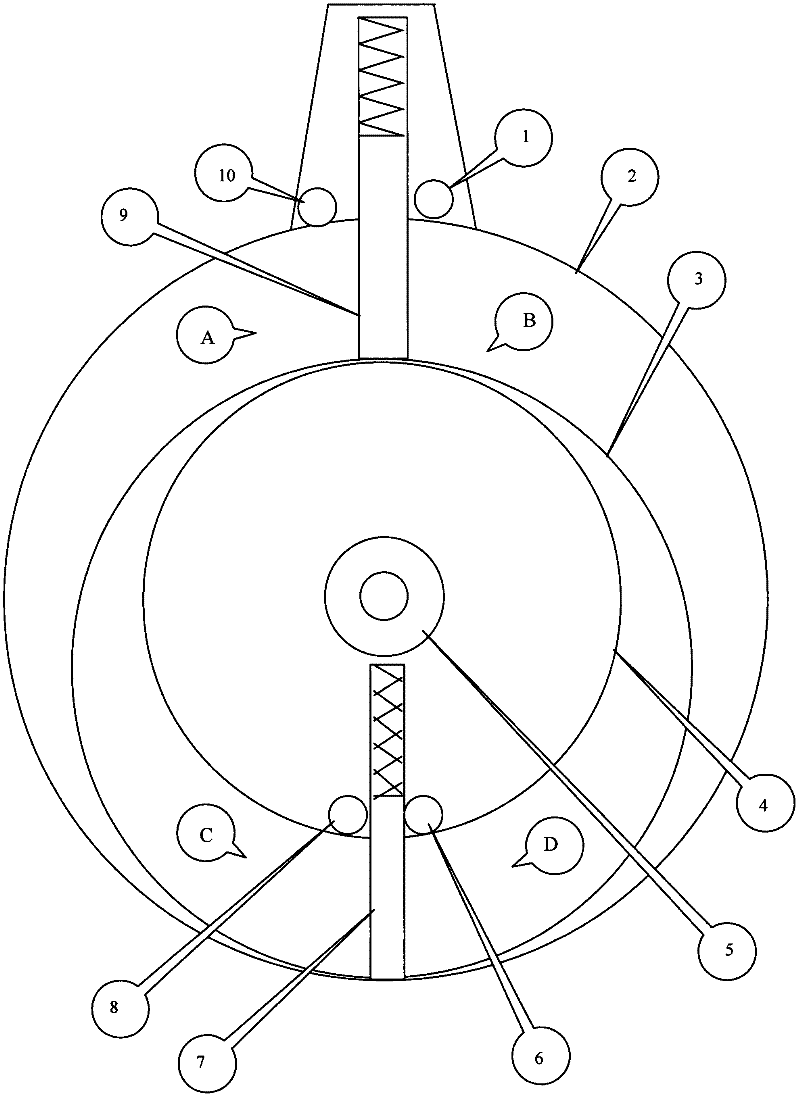

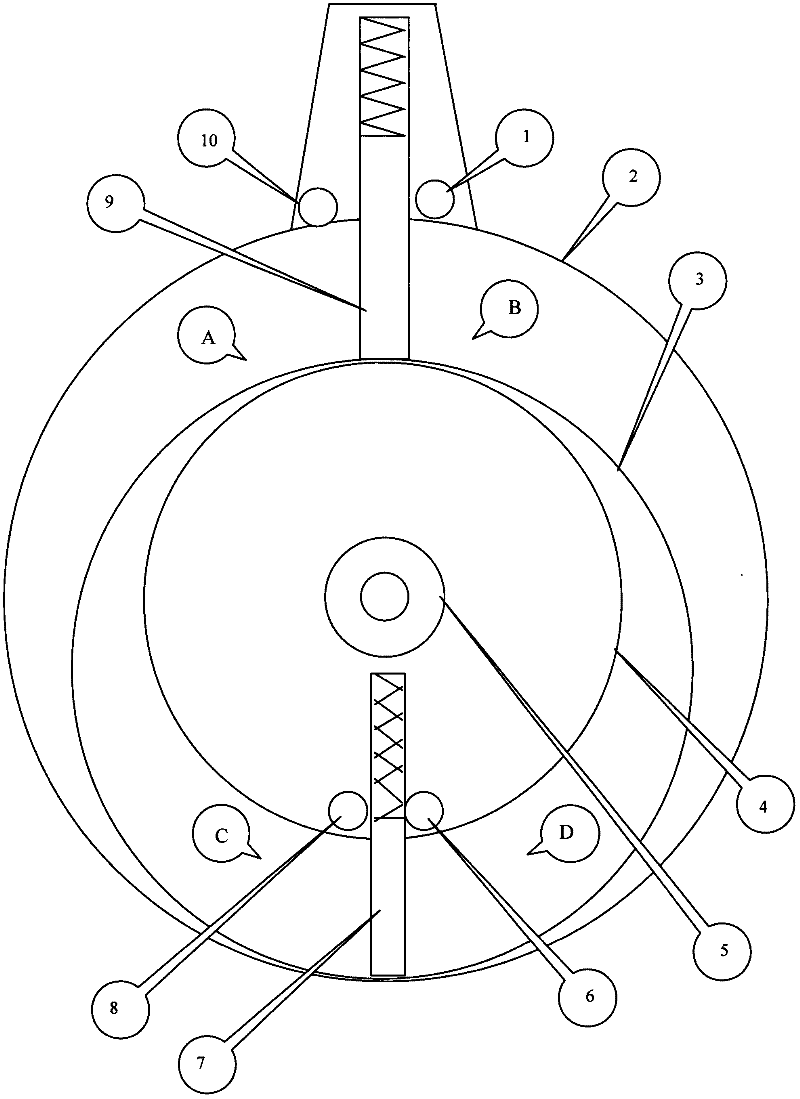

[0019] According to the drawings, A, B, C, and D are the four cycle-changing spaces inside and outside separated by the eccentric shaft swivel and two slides. The heating enters the intake of the C hot chamber in sequence—the exhaust of the D hot chamber—the intake of the B cold chamber—the exhaust of the A cold chamber. Due to the pressure difference between C and D and the pressure difference between B and A, Drive the eccentric shaft rotating ring clockwise to do work, so in the present invention, the system structure is simple and compact, the working medium gas work continuity is good without pulsation, compared with the piston type external combustion engine, it is beneficial to improve the thermal efficiency of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com