Process for preparing aluminum-glass-coated cubic boron nitride by using dry powder hierarchical packing method

A technology of cubic boron nitride and encapsulation method, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of many influencing factors, susceptibility to damage, pollution, etc., and achieve safe process routes, increased service life, good lubrication wet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

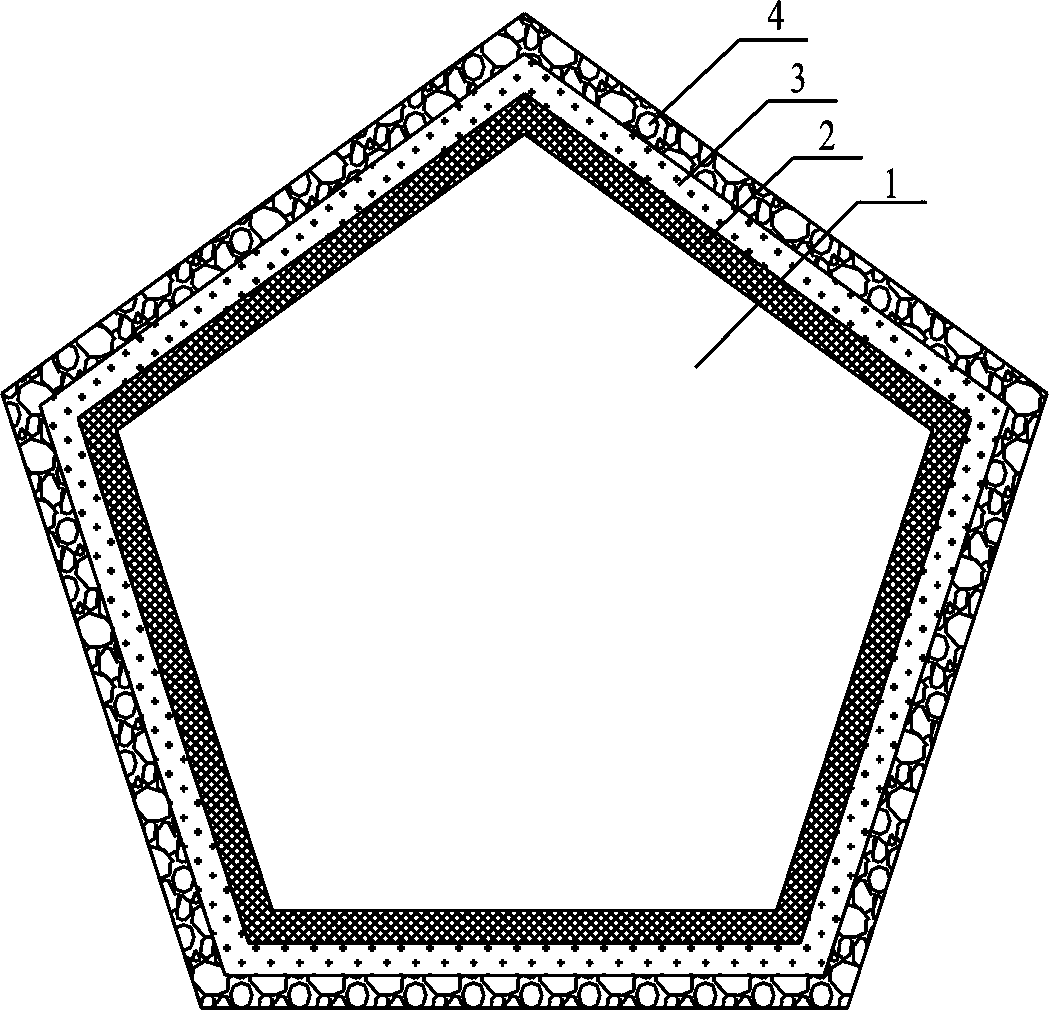

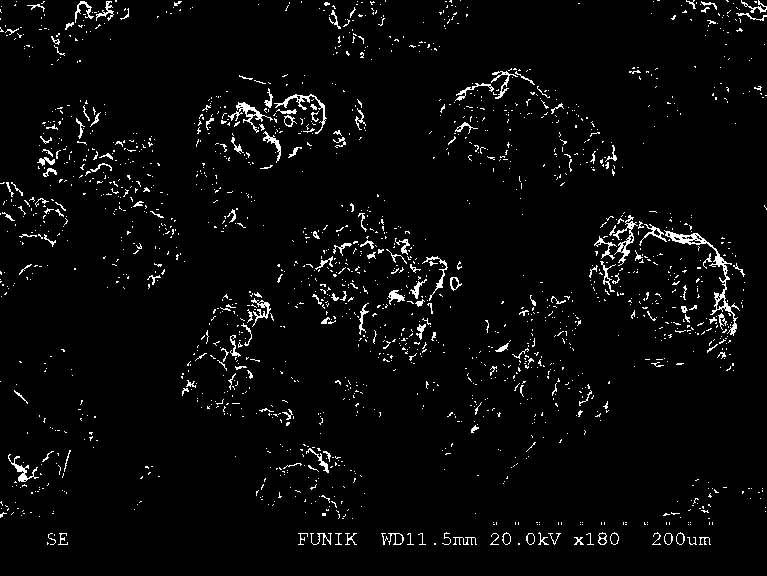

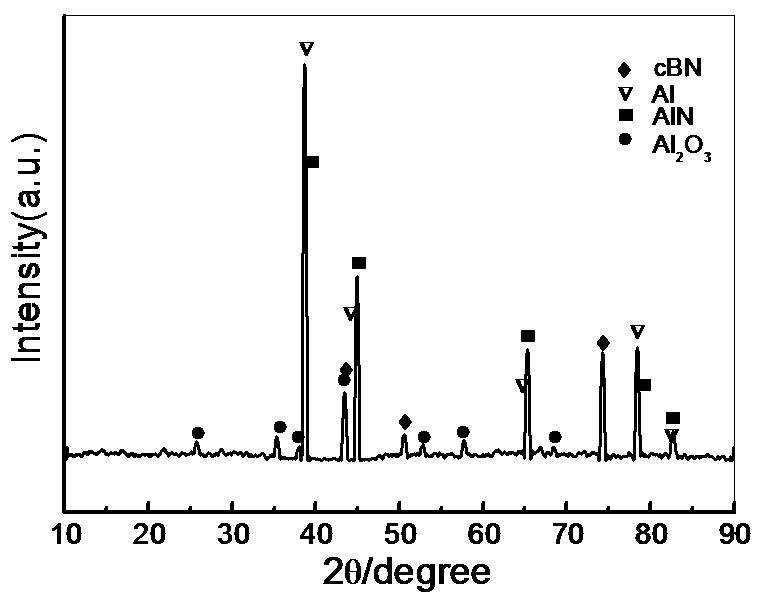

[0039] The process of preparing aluminum-glass coated cubic boron nitride by dry powder layered wrapping method, the steps are as follows:

[0040] Step (a), wrapping the outer layer of rosin on the surface of cubic boron nitride, the specific process is:

[0041] (a1) Put 10g of rosin and 12ml of ethanol (analytically pure, the same below) in the bottle to completely dissolve the rosin to prepare the ethanol solution of rosin;

[0042] (a2) Mix the cubic boron nitride (cBN for short) with the ethanol solution of the above-mentioned rosin at a ratio of 200cts:12ml, fully stir it evenly, spread it out into an open container, put it in an oven and dry it with air at room temperature until the ethanol The volatilization is complete, the rosin is dried and hardened, and then passed through a 100-mesh sieve, and the under-sieve is cubic boron nitride (s-cBN) wrapped in a uniformly dispersed rosin outer layer; among them, cBN is 120 mesh, and rosin is 300 mesh ;

[0043] In step (...

Embodiment 2

[0071] Basically the same as embodiment 1, the difference is:

[0072] In step (a), the cubic boron nitride is 120 mesh, and the rosin is 280 mesh; the dosage of the rosin, cubic boron nitride, and ethanol is: rosin 8g, cubic boron nitride 180cts, ethanol 12ml; pass through a 80-mesh sieve;

[0073] In step (b), glass powder pretreatment: after dry grinding the glass powder for 0.5 hours, melting at 1200°C for 3 hours, drying at 40°C, crushing and dry grinding for 2 hours, passing through a 280-mesh sieve; the aluminum powder is 280 mesh; In terms of mass ratio, glass powder: aluminum powder: cubic boron nitride wrapped with rosin=0.02:0.30:1.00;

[0074] In step (c), sintering and heat preservation at 760° C. in a resistance furnace for 1 hour; passing through an 80-mesh sieve.

Embodiment 3

[0076] Basically the same as embodiment 1, the difference is:

[0077] In step (a), the cubic boron nitride is 140 mesh, and the rosin is 200 mesh; the dosage of the rosin, cubic boron nitride and ethanol is: rosin 12g, cubic boron nitride 280cts, ethanol 12ml; pass through a 100 mesh sieve;

[0078] In step (b), glass powder pretreatment: after dry grinding the glass powder for 6 hours, melting at 1400°C for 1 hour, quenching with water, drying at 80°C, crushing and dry grinding for 6 hours, passing through a 320-mesh sieve; the aluminum powder is 320 mesh; in terms of mass ratio, glass powder: aluminum powder: cubic boron nitride wrapped with rosin = 0.07: 0.90: 1.00;

[0079] In step (c), sintering and heat preservation at 700° C. for 4 hours in a resistance furnace; passing through a 100-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com