Nano metal leaf and preparation method thereof

A nano-metal and leaf technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of harsh experimental conditions, complex and multi-step preparation process, and inability to scale production, etc., to achieve reaction Condition control, good dispersion and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

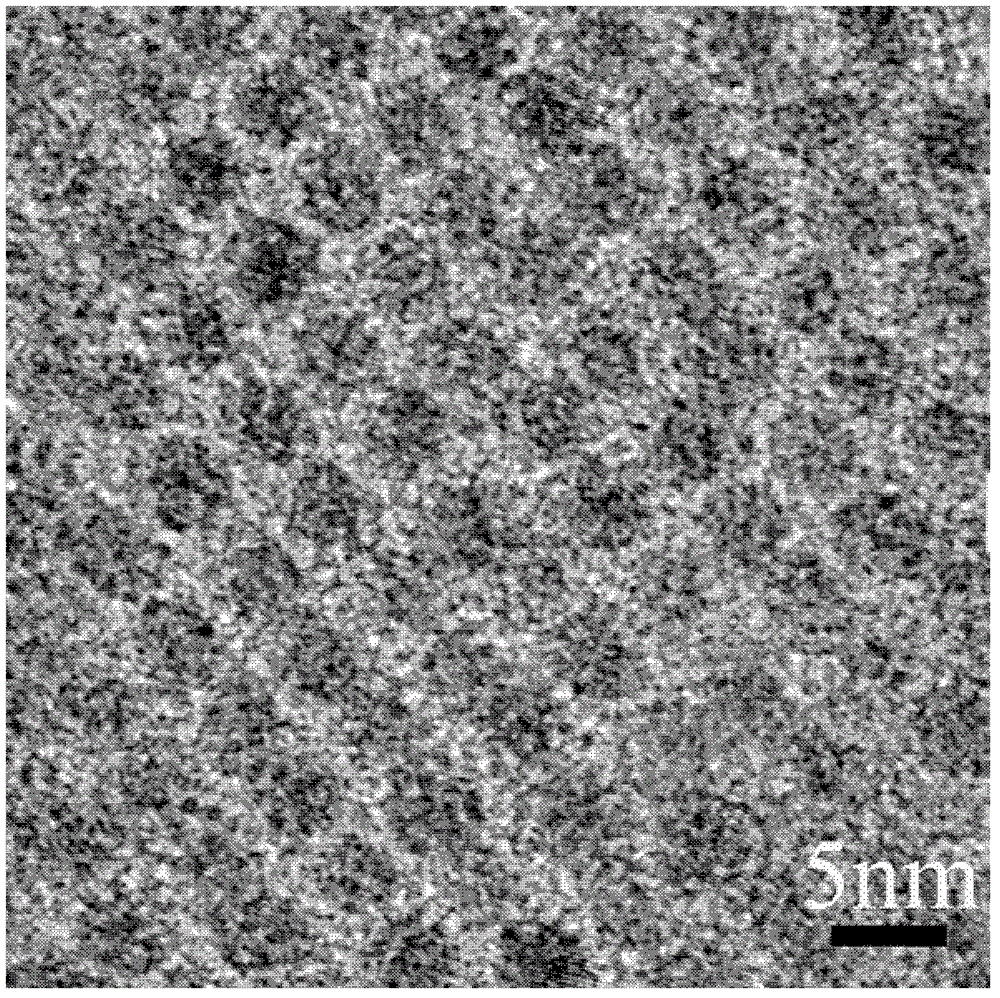

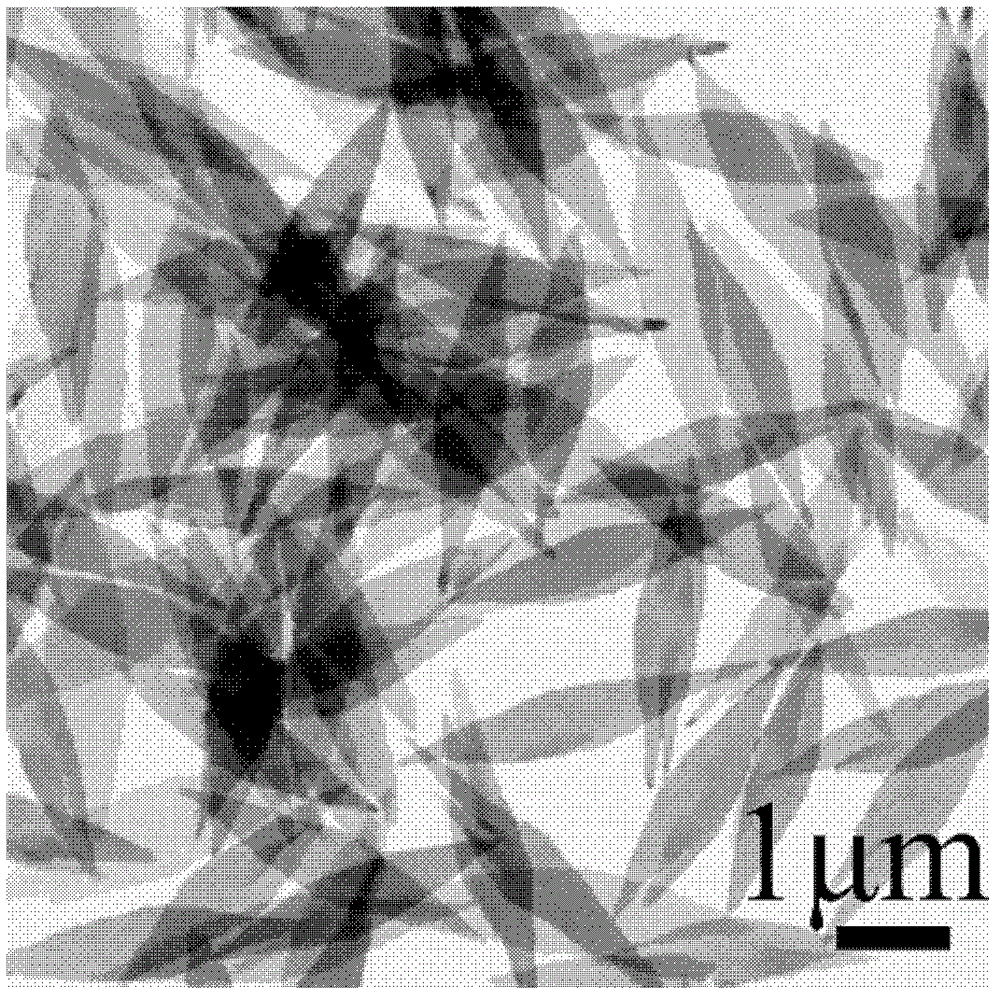

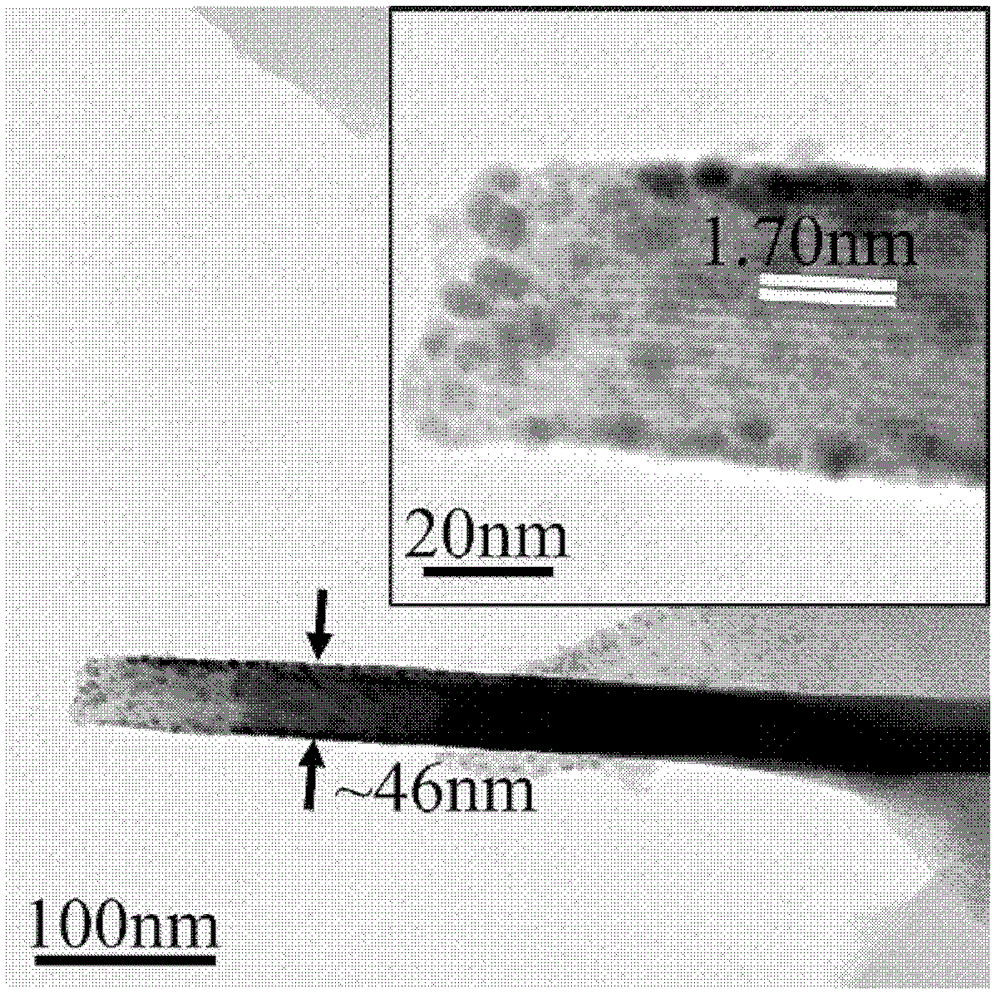

[0034] Example 1 The technical scheme of the present embodiment is: prepare the nano-silver particles of high monodispersity (such as Figure 1A shown), with a diameter of 4 ± 0.1 nm, and then dispersed it in a certain amount of cyclohexane; then, take 50 μL of cyclohexane solution containing nano-silver particles (50 mM) and 400 μL containing p-mercaptoaniline (50 mM) ethanol solution was mixed and reacted at room temperature for 4 hrs; after the reaction was completed, a polar solvent (such as ethanol) was added, centrifuged (10000 rpm, 5 minutes), washed and dried (60 ℃) to obtain a layer The shape and performance of nano-silver leaves with a structure are shown in Figure 1-4.

Embodiment 2

[0035] Example 2The technical solution of this embodiment is: prepare highly monodisperse gold nanoparticles with a diameter of 13 nm by thermal reduction, and then disperse them in a certain amount of n-hexane; then, take 100 μL containing gold nanoparticles (40 mM) n-hexane solution was mixed with 1000 μL N-methylpyrrolidone solution containing 3-mercaptobenzoic acid (40 mM), and reacted at room temperature for 6 hrs; after the reaction was completed, a polar solvent (such as ethanol) was added, and the After centrifugation (10000 rpm, 5 minutes), washing and drying (60 ℃), the product was dispersed in water to obtain a layered structure of gold nano leaves.

Embodiment 3

[0036] Example 3 The technical solution of this embodiment is: prepare highly monodisperse nano-copper particles with a diameter of 7.1 ± 0.5 nm by hydrothermal method, and then disperse them in a certain amount of dimethyl sulfoxide; then, take 50 μL containing The dimethyl sulfoxide solution of copper nanoparticles (20 mM) was mixed with 800 μL of methanol solution containing L-cysteine (80 mM), and reacted at room temperature for 20 hrs; after the reaction was completed, a polar solvent ( Such as ethanol), after centrifugation (10000rpm, 5 minutes), washing and drying (80 ℃), the nano-copper leaves with layered structure are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com