Full-automatic punching machine with manipulators and suitable for fastener production

A manipulator, fully automatic technology, applied in metal processing equipment, feeding devices, stripping devices, etc., can solve the problems of inability to accurately locate and control, prone to accidents, low safety, etc., achieve simple structure, improve safety, Control reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

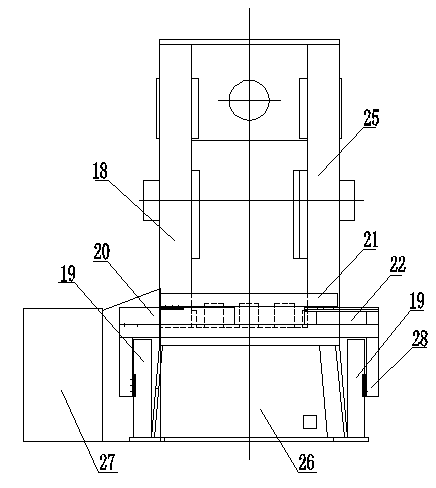

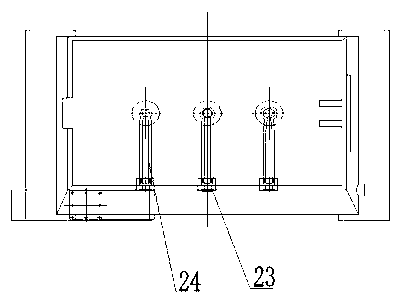

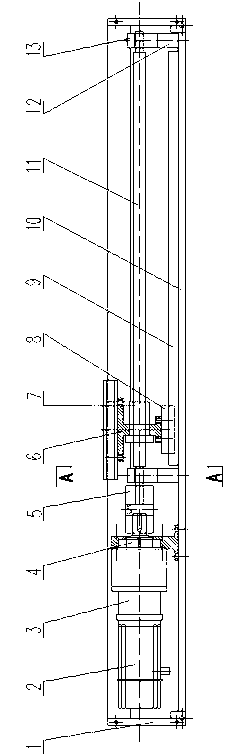

[0019] Such as figure 1 , figure 2 As shown, the punch press 18 of the present invention includes a bed 25, a base 26, a motor, and a control cabinet 27; vertically mounted up and down manipulators 19 are installed on the outer surfaces of the base 26, and the Π-shaped connecting plate 28 is sleeved outside the base 26, the first up and down The mobile manipulator and the second up and down mobile manipulator are respectively connected to the two inner sides of the Π-shaped connecting plate 28 by the sliding platform of the first up and down moving manipulator and the sliding platform of the second up and down moving manipulator, on the side above the Π-shaped connecting plate 28 Left and right translation manipulator 20 is installed, and support plate 22 is installed on the other side above Π shape connecting plate 28, and the sliding platform of lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com