Cooling and oil evacuation firefighting unit for fire extinguishing with liquid oil tank

A technology for fire-fighting devices and storage tanks, which is applied in packaging, fire rescue, transportation and packaging, etc. It can solve the problems of not being able to effectively suppress the flowing fire, and achieve the effects of convenient daily maintenance, improved fire extinguishing efficiency, and high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

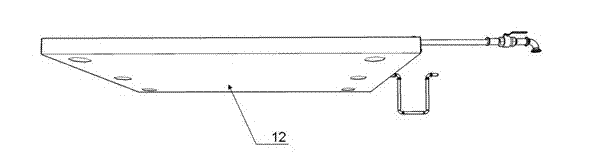

[0037] as attached Figure 1-6 As shown, the present invention can effectively extinguish the flowing fire by cooling and sealing. In this embodiment, the size of the whole device is about 5m*5m*0.25m, and the present invention can be used in conjunction with fire dikes and fire gratings. The water pump 1 is connected to the fire-fighting water source, the valve 2 can control the water volume, the delivery pipe 3 is connected to the valve 2, and the emergency cooling water is delivered to the tee pipe elbow 4 and the waterway tee pipe 5, and the cooling water is passed through the two water inlets 7. The water is sent to the box of the cooling and oil discharge fire-fighting device. The water inlet is close to the bottom plate 12, so that the temperature of the cooling water in the whole box shows a trend of rising and falling. The cooling water is directly cooled near the water inlet 7 to collect the leaked oil. Elbow 13, extension pipe section 14 and collection pipe section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com