Calcium dobesilate capsules and preparation method thereof

A technology for preparing calcium dobesilate and capsules, which is applied in the fields of capsule transportation, pharmaceutical formulations, anhydride/acid/halide active ingredients, etc. It can solve the problems of related substances not meeting the requirements, achieve great application value, and the method is simple and The effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

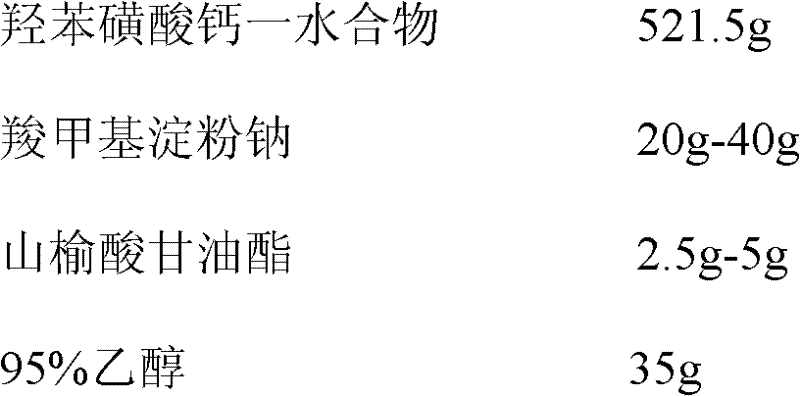

[0034] Example 1 prepares calcium dobesilate capsules:

[0035] serial number

ingredients

per 1000 capsules

1

Calcium dobesilate monohydrate

521.5g

2

5g

3

1.4g

4

95% ethanol

20g

[0036] (1) Calcium dobesilate monohydrate is sieved with 80 mesh.

[0037] (2) Magnesium stearate is sieved with 100 mesh, and sodium starch glycolate is sieved with 100 mesh.

[0038] (3) Put the calcium dobesilate monohydrate sieved in step (1) into a wet granulator, stir at a low speed (120 rpm) for 1 min, add 95% ethanol to granulate, and stir at a low speed for 3 min.

[0039] (4) Oven drying the granules prepared in step (3) at 60-65°C for 1.0 hour.

[0040] (5) After drying, the granules are sized with a 18-mesh galvanized hard mesh with a swing machine.

[0041] (6) Add the granules obtained in step (5) into a mixer for mixing, and simultaneous...

example 2

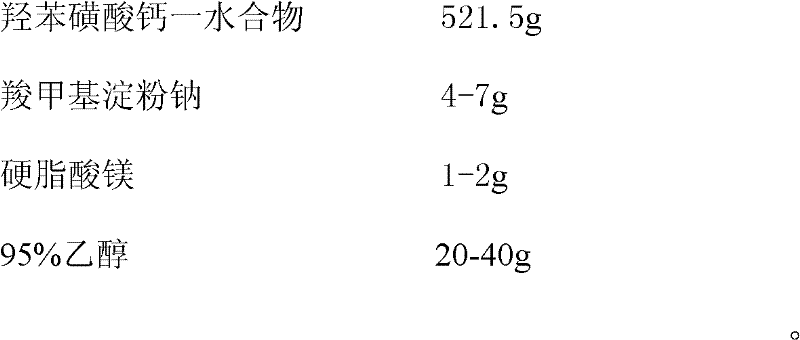

[0044] Example 2 prepares calcium dobesilate capsules

[0045] serial number

ingredients

per 1000 capsules

1

Calcium dobesilate monohydrate

521.5g

2

4.0g

3

Magnesium stearate

1.0g

4

95% ethanol

30g

[0046] (1) Calcium dobesilate monohydrate is sieved with 60 mesh.

[0047] (2) Magnesium stearate is sieved with 100 mesh, and sodium starch glycolate is sieved with 100 mesh.

[0048] (3) Put the calcium dobesilate monohydrate sieved in step (1) into a wet granulator and stir at a low speed for 1 min, add 95% ethanol to granulate, and stir at a low speed (120 rpm) for 3 min.

[0049] (4) Oven drying the granules prepared in step (3) at 60-65°C for 1.5 hours.

[0050] (5) After drying, the granules are sized with a 18-mesh galvanized hard mesh with a swing machine.

[0051] (6) Add the granules obtained in step (5) into a three-dimensional mixer for m...

example 3

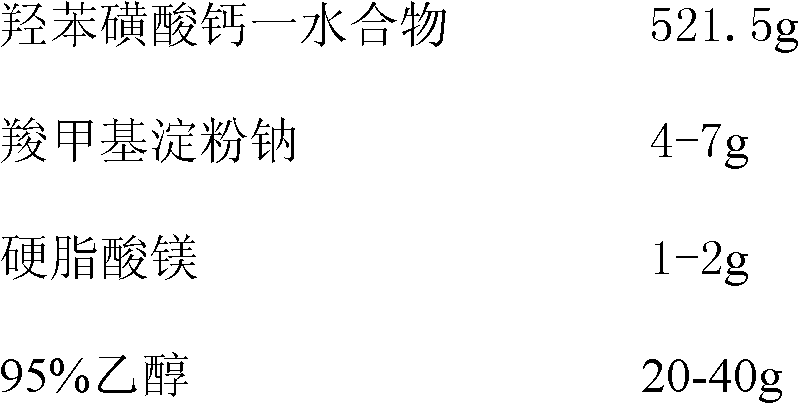

[0054] Example 3 prepares calcium dobesilate capsules

[0055] serial number

ingredients

per 1000 capsules

1

Calcium dobesilate monohydrate

521.5g

2

7.0g

3

2.0g

4

95% ethanol

40g

[0056] (1) Calcium dobesilate monohydrate is sieved with 40 mesh.

[0057] (2) Magnesium stearate is sieved with 100 mesh, and sodium starch glycolate is sieved with 100 mesh.

[0058] (3) Put the calcium dobesilate monohydrate sieved in step (1) into a wet granulator and stir at a low speed for 1 min, add 95% ethanol to granulate, and stir at a low speed (120 rpm) for 3 min.

[0059] (4) drying the granules prepared in step (3) in an oven at 60-65° C. for 2 hours.

[0060] (5) After drying, the granules are sized with a 18-mesh galvanized hard mesh with a swing machine.

[0061] (6) Add the granules obtained in step (5) into a three-dimensional mixer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com