Color retention preservative, and preparation method and application thereof

A preservative and color protection technology, applied in application, food preparation, food preservation, etc., can solve the problems of high cost and poor color protection effect, and achieve the effects of preventing spoilage, slowing down blackening, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 color protection and antistaling agent

[0033] (1) get bayberry leaf and wash, dry at 40 ℃ by blast for 24h, pulverize to obtain 40 mesh bayberry leaf dry powder;

[0034] (2) preparing an acetone solution with a volume percent concentration of 70%, and adding the ascorbic acid with a mass percent concentration of 0.1% in the acetone solution;

[0035] (3) Take 100g dried bayberry leaf powder, add it to the acetone solution obtained in step (2), and extract 3 times at 25° C. The amount of acetone solution each time is 1000 mL, and each extraction is 15 minutes; after extraction, filter and combine to obtain extract;

[0036] (4) The extract was evaporated under reduced pressure at 40°C to remove acetone, extracted 3 times with 1 volume of hexane, and the separated aqueous phase was extracted 3 times with 1 volume of dichloromethane, and the separated aqueous phase was reduced The organic solvent is removed by pressure evaporation to ob...

Embodiment 2

[0038] The preparation of embodiment 2 color protection and antistaling agent

[0039] (1) wash bayberry leaves, dry at 40 ° C by blast for 12h, pulverize to obtain 40 mesh bayberry leaf dry powder;

[0040] (2) preparation volume percent concentration is 60% acetone solution, and adding mass percent concentration is 0.05% ascorbic acid in this acetone solution;

[0041] (3) Take 100g dried bayberry leaf powder, add it to the acetone solution obtained in step (2), and extract 3 times at 35° C. The amount of acetone solution each time is 1000 mL, and each extraction is 15 minutes; after extraction, filter and combine to obtain extract;

[0042] (4) The extract was evaporated under reduced pressure at 40°C to remove acetone, extracted with 1 volume of hexane, the separated aqueous phase was extracted with 1 volume of dichloromethane, and the separated aqueous phase was evaporated under reduced pressure to remove organic Solvent to obtain color and preservative;

[0043] (5) f...

Embodiment 3

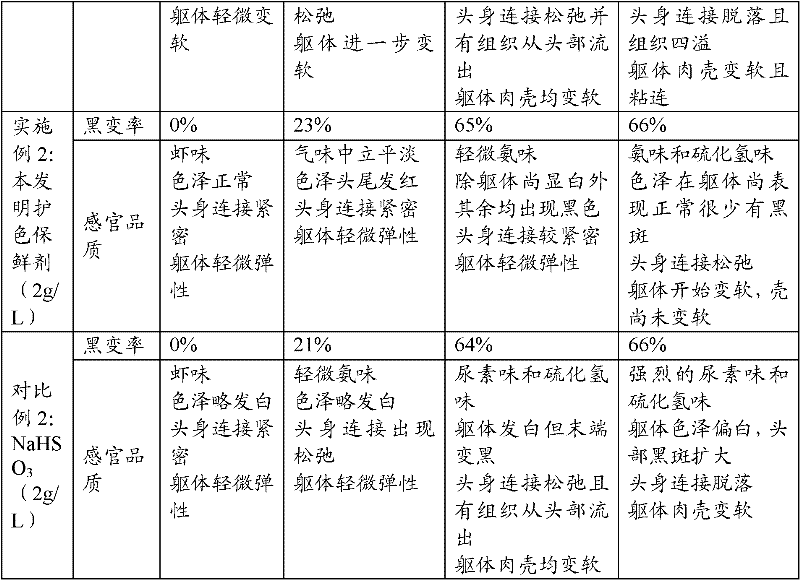

[0044] Embodiment 3 adopts color protection and antistaling agent to process prawns

[0045] (1) get the dry powder that 2g embodiment 1 makes, be dissolved in 1L of distilled water, fully stir and dissolve, and obtained concentration is 2g / L of color protection and antistaling agent aqueous solution;

[0046](2) Choose fresh and live prawns with uniform size, freshness and no damage, randomly select groups, 20 in each group, wash them with water and add ice to die suddenly;

[0047] (3) 20 prawns were placed in the 2g / L color protection and antistaling agent aqueous solution obtained in step (1), and soaked for 1min;

[0048] (4) Take out the prawns, drain the water, put them into a fresh-keeping bag, and place them in a refrigerator at 0-4°C for refrigeration;

[0049] (5) After refrigerating for 4 days, the prawns were taken out, cooked, and the sensory quality of the prawns was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com