Dinotefuran micron-emulsion and preparation method thereof

A technology of dinotefuran microemulsion and dinotefuran, applied in botany equipment and methods, insecticides, biocides, etc., can solve environmental pollution and other problems, and achieve low packaging requirements, significant drug efficacy, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: 5% dinotefuran microemulsion

[0023]

[0024] Mix dinotefuran with solvent, surface active agent and co-solvent thoroughly, then add water and stir well to form microemulsion.

Embodiment 2

[0025] Embodiment 2: Physical and chemical performance measurement

[0026] Get the dinotefuran microemulsion prepared in Example 1 and carry out the physical and chemical performance test, the results are as follows:

[0027] Appearance: clear and transparent single-phase liquid;

[0028] Transparent temperature area: minus 5°C to above 60°C;

[0029] Low temperature stability: no delamination and crystallization at -5°C for 2 weeks;

[0030] Thermal storage stability: the decomposition rate of active ingredients is less than 3% at (54±2)°C for 2 weeks;

[0031] Emulsion stability: Emulsion diluted with any proportion of water is stable;

[0032] Stability over time: Stable at room temperature.

Embodiment 3

[0033] Embodiment 3: field efficacy test

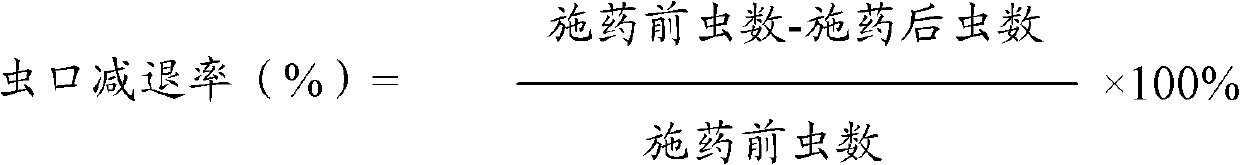

[0034] The dinotefuran microemulsion prepared in Example 1 and a commercially available certain dinotefuran granule were used for field efficacy test. 5 treatments were set up in the test, and each application rate was shown in Table 1. Every treatment was repeated 4 times. With reference to the "Pesticide Field Efficacy Test Guidelines" of the Ministry of Agriculture, the number of insects was investigated in 1-3 days and 7 days after spraying, and the statistics and results were collected. The calculation results are shown in Table 1. The insect population reduction rate and control effect are calculated according to the following formula.

[0035]

[0036]

[0037]

[0038] Among them, PT 0 Indicates the number of living insects in the chemical treatment area before treatment; PT 1 Indicates the number of living insects in the chemical treatment area; CK 0 Indicates the number of living insects in the blank control are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com