Testing structure capable of effectively testing shallow trench isolation filling capability

A technology for testing structure and filling capability, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve problems such as inability to obtain STI filling capability, generation of holes 202, and inconsistent depth of etching test structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An effective test structure for testing the filling capability of shallow trench isolation of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

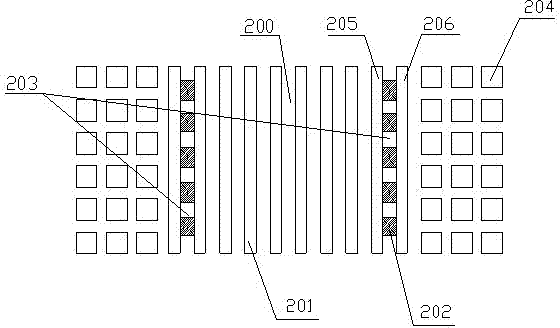

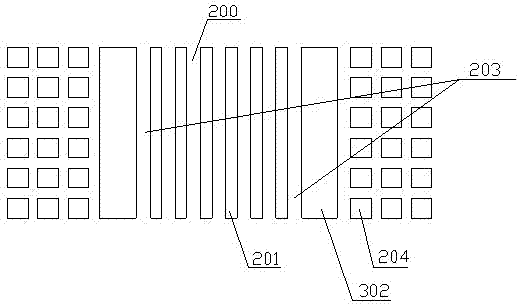

[0023] image 3 A schematic diagram of a test structure for effectively testing the filling capability of shallow trench isolation according to a preferred embodiment of the present invention is shown. Specifically, on silicon substrates ( image 3 Not marked in, you can refer to figure 2 A number of first trenches 200 for forming shallow trench test structures are etched on the silicon substrate 201 in The trenches 200 are distributed in the middle of the test structure, image 3 Among the outermost trenches 203, those skilled in the art understand that the outermost trenches 203 are also the first trenches 200, and the difference from other first trenches 200 is that the outermost trenches 203 are part of the test structure. The outermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com