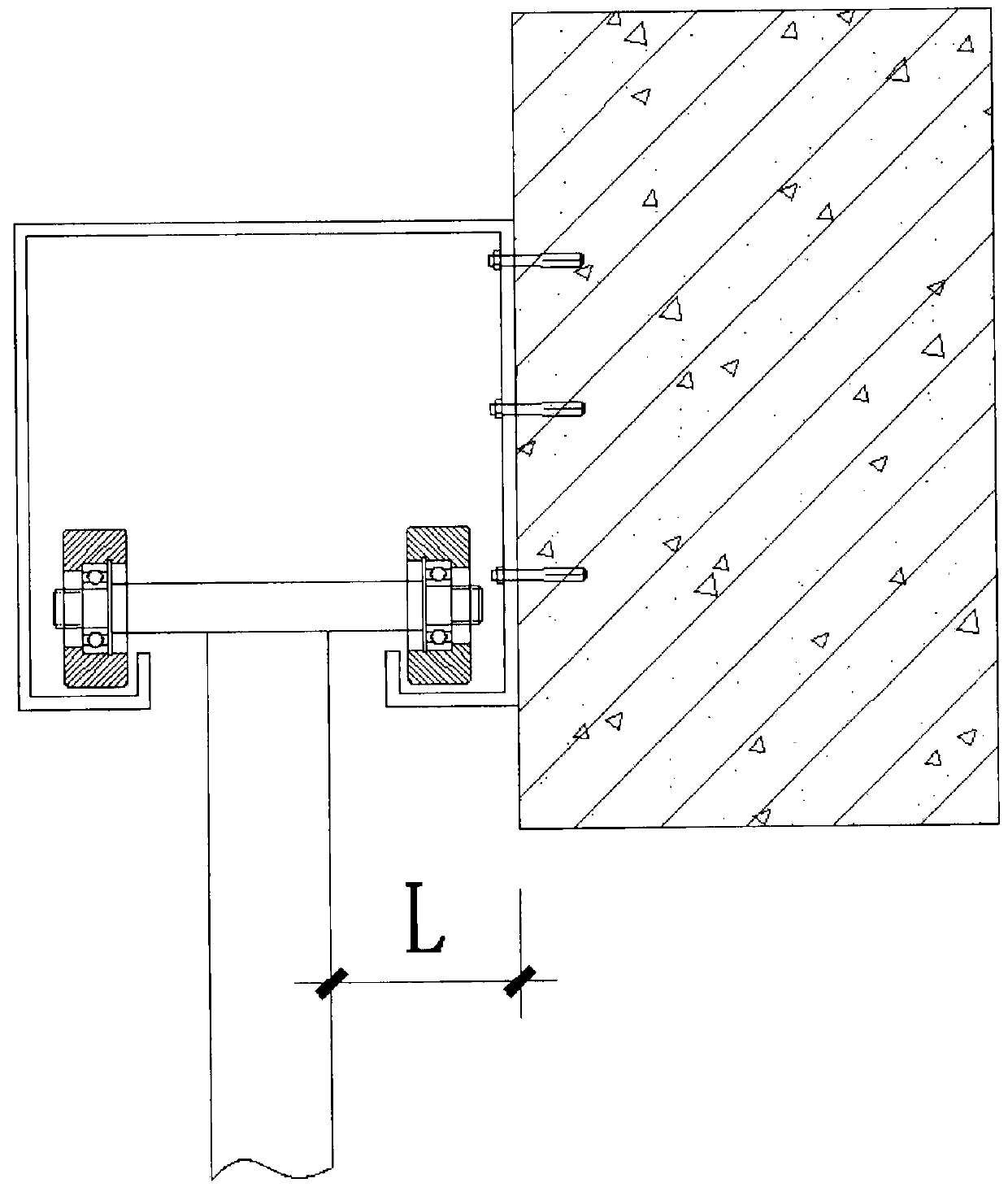

Main frame for suspension type electric sliding door

A main frame, suspended technology, applied in the direction of the power control mechanism, the suspension device of the wing fan, the door/window accessories, etc., can solve the problem of being unable to bear the prying torque, etc., and achieves low production process requirements, saving width, and reliable effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

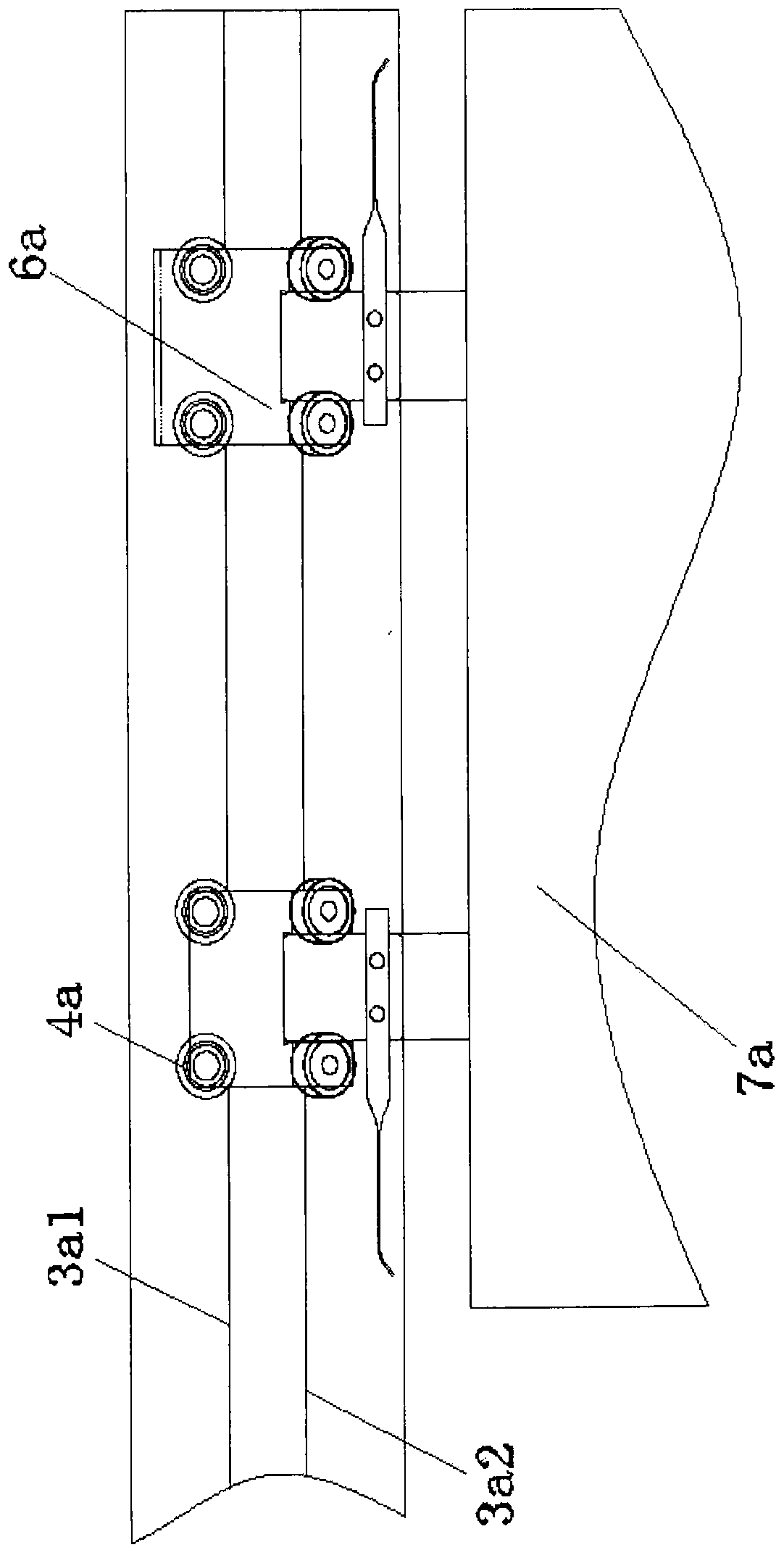

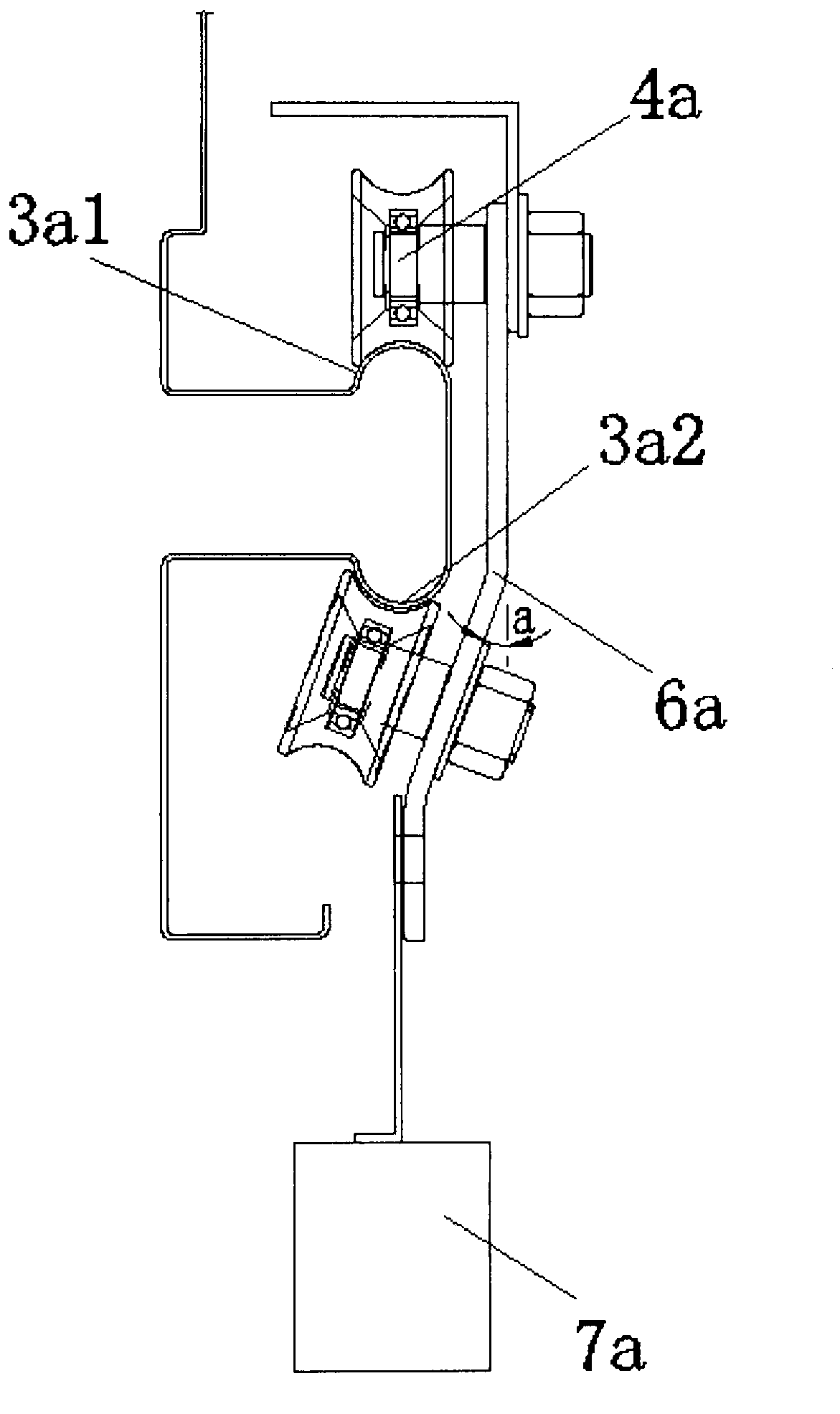

[0056] Embodiment 2 of the present invention: see Figure 4 to Figure 9 . This embodiment is basically the same as Embodiment 1, the difference is that a mounting piece 17 is welded to the side of the door leaf fixing piece 6, four mounting holes 18 are arranged on the mounting piece, the height of the mounting piece is less than the outer diameter of the roller, and the anti-skid plate 8 is There are two halves on the left and right, each half is provided with a half hole in the lower part, and the two halves are respectively fixed on the left and right sides of the mounting piece through two mounting holes 18, after fixing, the respective half holes in the lower part of the two halves are combined to form a curved surface that matches the track That is the hole 9 through which the track passes. Since the door leaf fixing piece and the anti-skid plate are split, the installation method does not need to pass the door leaf fixing piece and the anti-skid plate through the track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com