Microwave heating super early strength cement concrete pavement repair material and preparation method thereof

A technology of microwave heating and repairing materials, which is applied in the direction of manufacturing tools and ceramic molding machines, etc., can solve the problems of poor durability, peeling, poor adaptability to the use environment, etc., achieve good stability and anti-aging performance, promote formation as soon as possible, and shorten condensation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw materials of this embodiment are combined according to the following mass ratio, cement: silica fume: fly ash: fine ground calcium carbonate: superplasticizer: calcium oxide: calcium chloride: sodium sulfate=1: 0.1: 0.1: 0.1: 0.005 :0.012:0.03:0.01. Wherein, the cement is a mixture of 52.5R ordinary Portland cement and 62.5 sulphoaluminate cement, and its mass ratio is ordinary Portland cement: sulphoaluminate cement=0.3:0.7, and the water consumption is the total mass of raw materials 40% of.

[0042] The preparation method of microwave heating super-early-strength cement concrete pavement repair material of the present invention comprises the following steps:

[0043] (1) Mix the raw materials according to the following mass ratio:

[0044]Among them, cement: silica fume: fly ash: fine ground calcium carbonate: superplasticizer: calcium oxide: calcium chloride: sodium sulfate = 1: 0.1: 0.1: 0.1: 0.005: 0.012: 0.03: 0.01, the water consumption is 40% of the ...

Embodiment 2~10

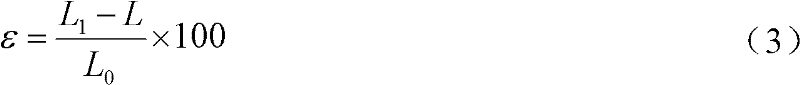

[0050] The raw materials and mass ratios of the microwave heating super-early-strength cement concrete pavement repair materials of Embodiment 2~10 are (ordinary Portland cement+sulfoaluminate cement): silica fume: fly ash: fine ground calcium carbonate: High-efficiency water reducer: calcium oxide: calcium chloride: sodium sulfate = 1: 0.1: 0.1: 0.1: 0.005: 0.012: 0.03: 0.01, the water consumption is 40% of the total mass of raw materials, of which ordinary Portland cement and sulfur aluminum The mass ratio and strength grade type of acid salt cement are different, see Table 1 for details; in addition, Examples 2-9 prepared the test pieces according to the preparation process described in Example 1, while the surface of the formed test piece in Example 10 was covered with plastic film Cover it and place it in an environment with a humidity of 90% and a temperature of 20°C for curing.

[0051] Table 1 Cement used in repair materials and mass ratio

[0052] serial num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com