Laminated glass with antenna function

A technology of laminated glass and antenna, which is applied in the direction of antenna, windshield, antenna parts, etc., can solve the problems of affecting the appearance of laminated glass and the driver's line of sight, complicated process, etc., achieve good capacitive coupling effect, easy process, and not easy bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

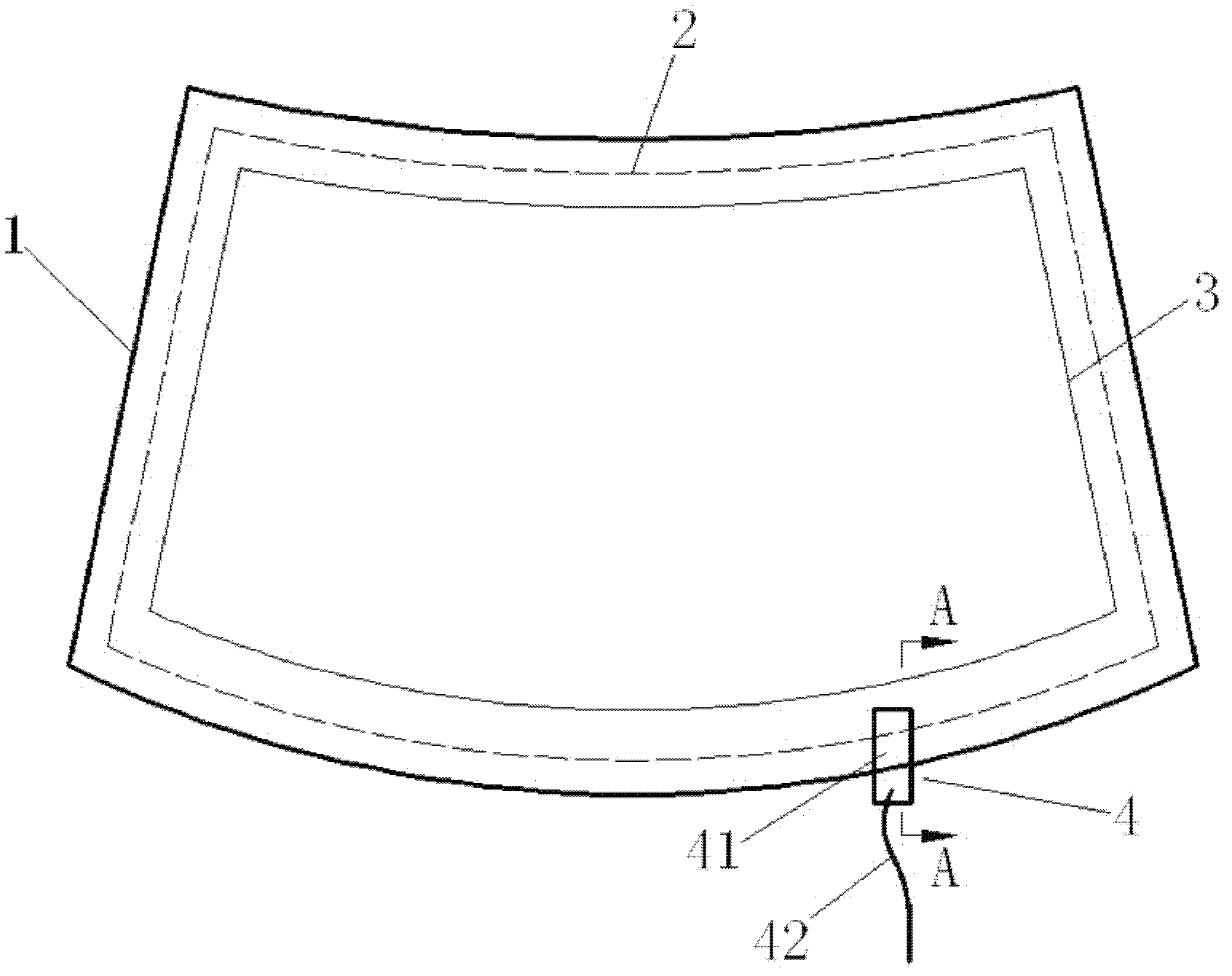

[0033] Schematic reference figure 1 , take a front-shield laminated glass 1 with a small side of 1090mm, a large side of 1410mm, and a height of 850mm, and use green glass + green glass combination. On the inner surface of the outer glass 11, the two hypotenuse edge areas of the glass are printed with a width of 30 mm and the two parallel edge areas of the glass are printed with a black ink printing edge 3 with a width of 50 mm, and the inner glass 12 faces the PVB film. The glass surface of sheet 5 is evenly coated with a single silver low-emissivity coating 2 with a light transmittance greater than 70%. The surface resistance of the film surface is 7.9-8.3Ω / □. High reflectivity, with good thermal insulation properties. The contour of the conductive coating 2 is 20 mm away from the edge of the glass, so the contour of the conductive coating 2 is outside the ink border 3 , and the contour of the black ink border 3 blocks the contour of the conductive coating 2 . The antenna ...

Embodiment 2

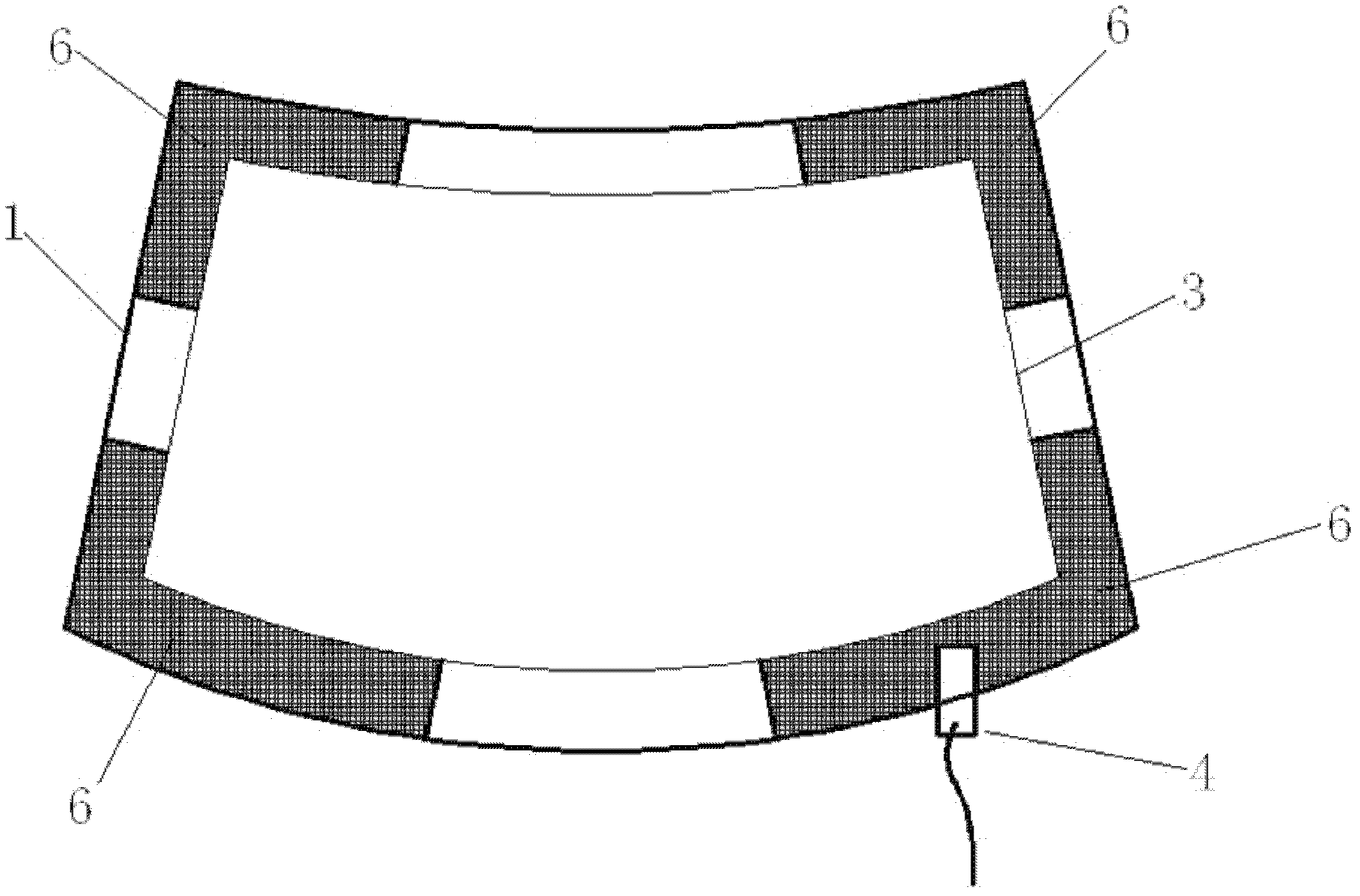

[0045] Schematic reference Figure 4 , Take the front windshield laminated glass 1 with a small side of 1090mm, a large side of 1410mm, and a height of 850mm, and use white glass + white glass combination. On the inner surface of the outer glass 11, the two hypotenuse edge areas of the glass are printed with a width of 30 mm and the two parallel edge areas of the glass are printed with a black ink printing edge 3 with a width of 50 mm, and the inner glass 12 faces the PVB film. The glass surface of sheet 5 is evenly coated with double-silver low-emissivity coating 2 with light transmittance greater than 70%. The surface resistance of the film surface is 2.5-3Ω / □. High reflectivity, with good heat insulation performance. The contour of the conductive coating 2 is 2mm away from the solid edge of the black ink border 3, then the contour of the conductive coating 2 is within the ink border 3 and within the field of vision, and the contour of the black ink border 3 will not block ...

Embodiment 3

[0051] Schematic reference Figure 4 , take a front-shield laminated glass 1 with a small side of 1175mm, a large side of 1445mm, and a height of 925mm, and use a combination of green glass and green glass. The two hypotenuse edge areas of the glass on the inner surface of the outer glass 11 are printed with black ink printing edges 3 with a width of 25 mm and two parallel edge areas of the glass with a width of 150 mm, and the inner glass 12 faces the PVB film. The glass surface of sheet 5 is evenly coated with a single silver low-emissivity coating 2 with a light transmittance greater than 70%. The surface resistance of the film surface is 7.9-8.3Ω / □. High reflectivity, with good thermal insulation properties. The contour of the conductive coating 2 is 2mm away from the solid edge of the black ink border 3, then the contour of the conductive coating 2 is within the ink border 3 and within the field of vision, and the contour of the black ink border 3 will not block the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com