Bio-stimulant for improved plant growth and development

A technology for promoting plant growth and plant development, applied in plant growth regulators, botanical equipment and methods, biocides, etc., and can solve problems such as unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] fermented broth

[0036] Bacteria (Lactobacillus plantarum, Streptococcus thermophilus, Propionibacterium freudenii) and yeast (Saccharomyces cerevisiae) were isolated and cultured using standard methods in the art. As the substrate of the culture medium, Diffco supplemented with the following components was used: TM Lactobacillus MRS culture medium (Diffco TM Lactobacilli MRS Broth).

[0037] Table 1. Composition of the fermented broth (all components per liter of broth)

[0038] Diffco TM Lactobacillus MRS culture medium

55g

urea

2g

1.25mL

Syrup powder extracted from sugar cane

2.5g

[0039] Broth was prepared by boiling for 1 min with constant stirring. This ensures complete dissolution of the culture medium matrix, urea and syrup.

[0040] The culture solution was then placed in an autoclave for sterilization (121° C., 15 minutes), and then poured into a sterilized 20 L bioreactor....

Embodiment 2

[0043] Preparation of formulations with dissolved urea

[0044] The urea fertilizer granules were dissolved in water at a concentration of 40kg urea per 197L volume of water. Dissolution is aided by stirring, but no heating is required.

[0045] The dissolution of urea is an endothermic process, and the time required for dissolution depends on the concentration of urea, the total volume, the initial temperature of the water and the stirring method. With constant stirring and an initial water temperature of 12°C, it took 7 minutes for the above concentrations and volumes of urea (sourced from Ballance Agri-nutrients Limited, Tauranga, New Zealand) to completely dissolve. The type and amount of hardening agent added when producing urea granules may affect the rate at which urea dissolves in water.

[0046] The pH value of the dissolved urea solution is about 9.0. However, most nitrogen was found to exist in organic form. Titration analysis well known in the art shows that, b...

Embodiment 3

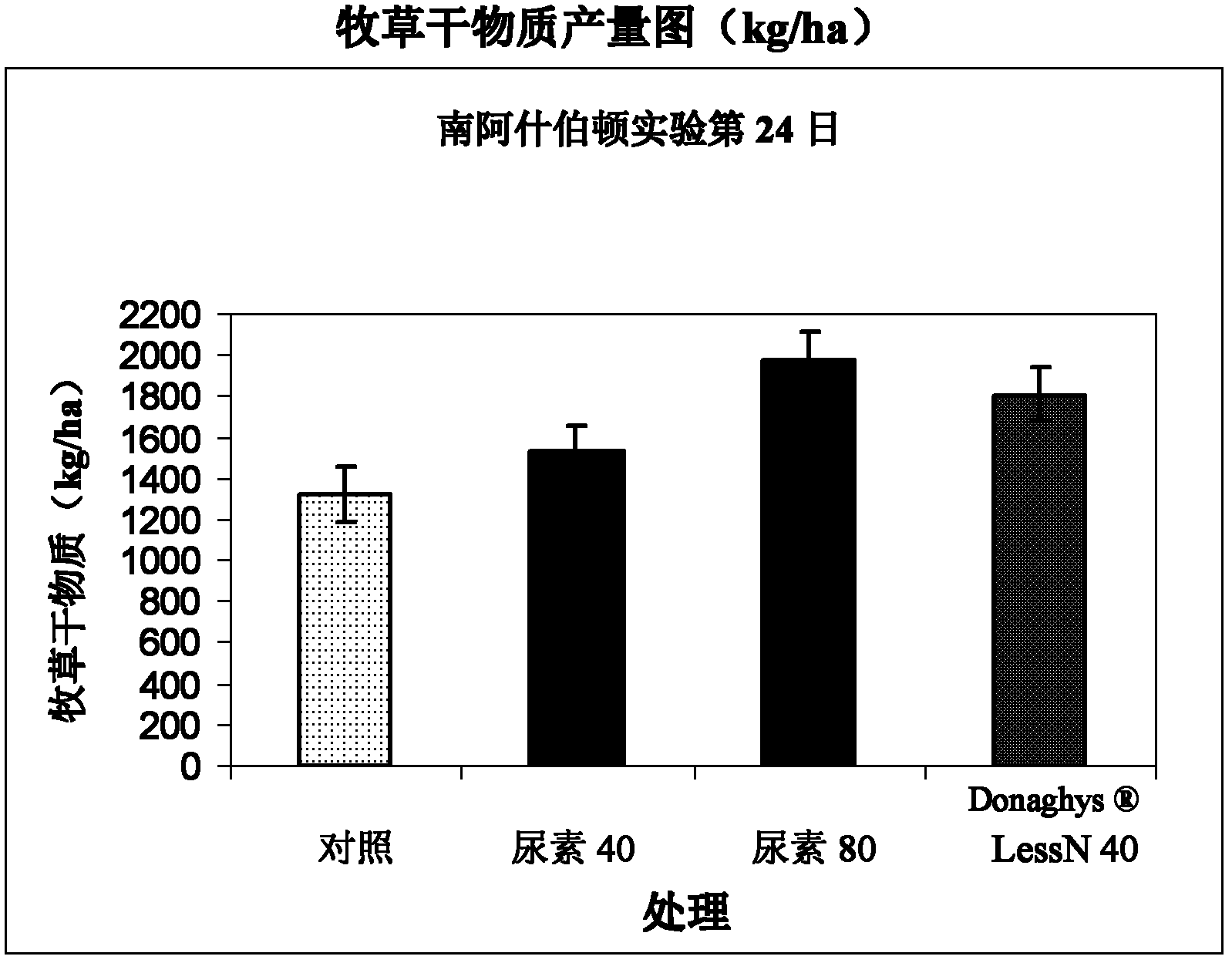

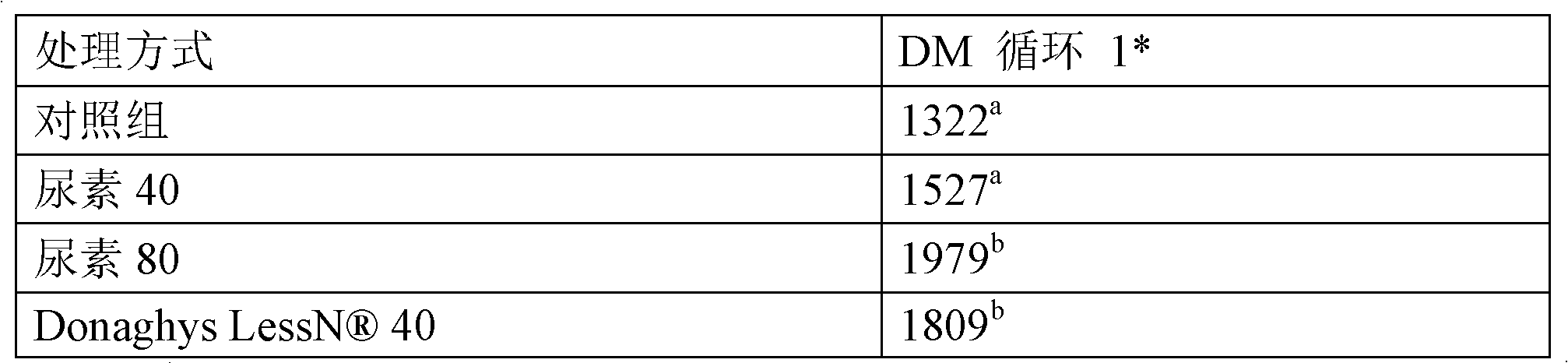

[0050] Field trials using the formulation with dissolved urea fertilizer on pasture grass

[0051] Introduction: The purpose of the field trial was to verify that Donaghys (3L / ha) in combination with 40kg / ha urea (18kg N) increases forage dry matter (DM) equivalent to the level of 80kg / ha urea (37kg N / ha) alone. Grass Master (GM) probe was used to measure the DM of pasture on the first day (before treatment, base point value) and 21 days after treatment. The GM probe estimates DM accumulation through a preprogrammed calibration equation provided by the manufacturer.

[0052] METHODS: In December 2007, irrigated dairy farms were selected from Central Canterbury, New Zealand. Choose a paddock that is evenly covered with freshly grazed pasture to reduce variation between zones. The paddock has just been grazed and is in the regrowth phase. During the test period, the livestock were driven out of the test area.

[0053] A completely randomized block design (CRBD) including 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com