Self-adjusting Q laser crystal material and purpose thereof

A laser crystal and self-adjusting technology, applied to lasers, laser parts, phonon exciters, etc., can solve the problems of high price, difficult design, and bulky volume, and achieve the effect of simple production and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

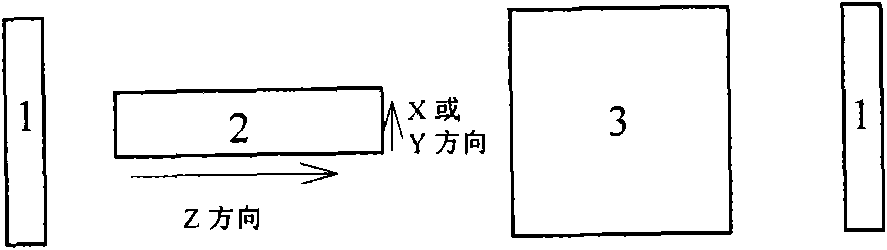

Image

Examples

Embodiment 1

[0017] Embodiment 1: making Na 3 La 8.7 Nd 0.3 B 8 o 27 Self-Q-switched pulsed laser

[0018] Massive Na 3 La 8.7 Nd 0.3 B 8 o 27 :Na 2 CO 3 :H 3 BO 3 : NaF = 1: 7.5: 6.5: 9 ingredients, using high temperature flux method to grow Na 3 La 8.7 Nd 0.3 B 8 o 27 crystals, in which Na 2 CO 3 、H 3 BO 3 and NaF as compound flux, Na 3 La 8.7 Nd 0.3 B 8 o 27 It is sintered according to the stoichiometric ratio of ingredients.

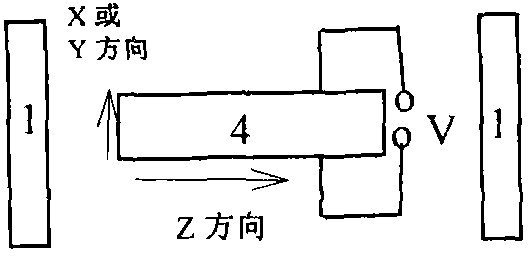

[0019] like figure 2 As shown, the Na grown in this example 3 La 8.7 Nd 0.3 B 8 o 27 The crystal is cut along the physical optical axis X, Y and Z directions of the crystal to make a device (marker "4" in the figure), the length in the Z direction is l=20mm, the width w=10mm, the thickness in the X direction is d=4mm, and the Z direction is The direction of light is passed, and the X direction is coated with a gold conductive film; and an electric field V is applied in the physical X direction or the physical Y direction; the cry...

Embodiment 2

[0020] Embodiment 2: making Na 3 La 8 YB 8 o 27 Self-Q-switched pulsed laser

[0021] The pumping method is the same as in Example 1, the difference is that the material used is Na 3 La 8 YB 8 o 27 crystals, growing Na 3 La 8 YB 8 o 27 The raw materials used in the crystal are sintered according to their stoichiometric ratio. The length in the Z direction is l=25mm, the width is w=15mm, the thickness in the X direction is d=5mm, the Z direction is transparent, the X direction is coated with silver conductive film, and the emission wavelength is 980nm. A laser diode side-pumps the crystal to achieve a laser output of 1.03 μm.

Embodiment 3

[0022] Embodiment 3: making Na 3 La 6 Er 0.3 Yb 2.7 B 8 o 27 Self-Q-switched pulsed laser

[0023] The pumping method is the same as in embodiment 1 or embodiment 2, the difference is that the material used is Na 3 La 6 Er 0.3 Yb 2.7 B 8 o 27 crystals, growing Na 3 La 6 Er 0.3 Yb 2.7 B 8 o 27The raw materials used in the crystal are sintered according to their stoichiometric ratio. The length in the Z direction is l=25mm, the width is w=15mm, the thickness in the Y direction is d=7mm, the Z direction is transparent, the Y direction is coated with a gold conductive film, and the emission wavelength is 980nm. A laser diode side-pumps the crystal to achieve a laser output of 1.55 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com