High-friction synthetic brake shoe for high-power xhn5 locomotive and its preparation method and application

A technology of synthesizing brake shoes and phenolic resins, applied in brakes, mechanical equipment, brake parts, etc. where brake elements interact with rails, can solve problems such as metal inlay, achieve high compressive strength and hardness, and improve friction stability , expensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example is used to illustrate the high-friction synthetic brake shoe and its preparation method of the present invention.

[0036] (1) Raw material mixing:

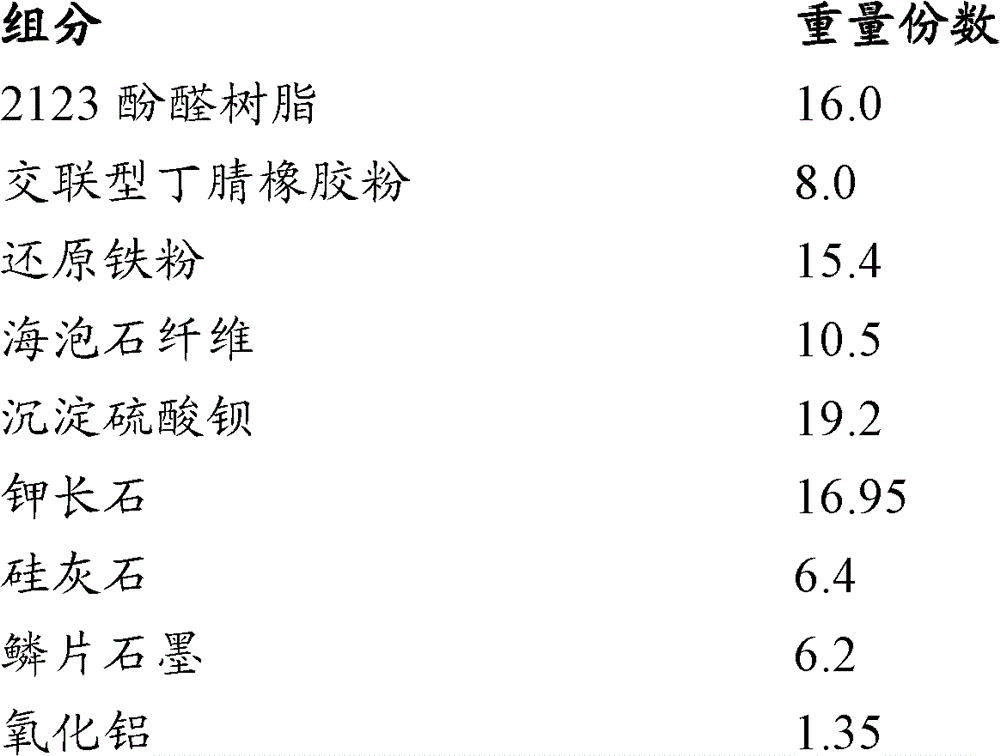

[0037] The components of the high-friction synthetic brake shoe and their proportions by weight are as follows:

[0038]

[0039] The specifications of the above raw materials are: 2123 phenolic resin: curing speed 60-90 seconds / 160°C, softening point 100-105°C, free phenol content 4%; nitrile rubber powder: cross-linked type, fineness 40 mesh; reduced iron Powder: iron content 98%, fineness 80 mesh; sepiolite fiber: MY-A type, Hebei Mingyang Company, fiber length 0.2-5mm, moisture content 3%, whiteness 80%, sand content 1%; Barium sulfate: white amorphous powder, barium sulfate content 99%, fineness above 200 mesh; wollastonite: light gray fibrous, aspect ratio 10:1, SiO 2 content of 51.75%, CaO content of 48.25%; potassium feldspar: fineness greater than 200 mesh, potassium oxide content of 8.9%; graphi...

Embodiment 2

[0046] This example is used to illustrate the high-friction synthetic brake shoe and its preparation method of the present invention.

[0047] (1) Raw material mixing

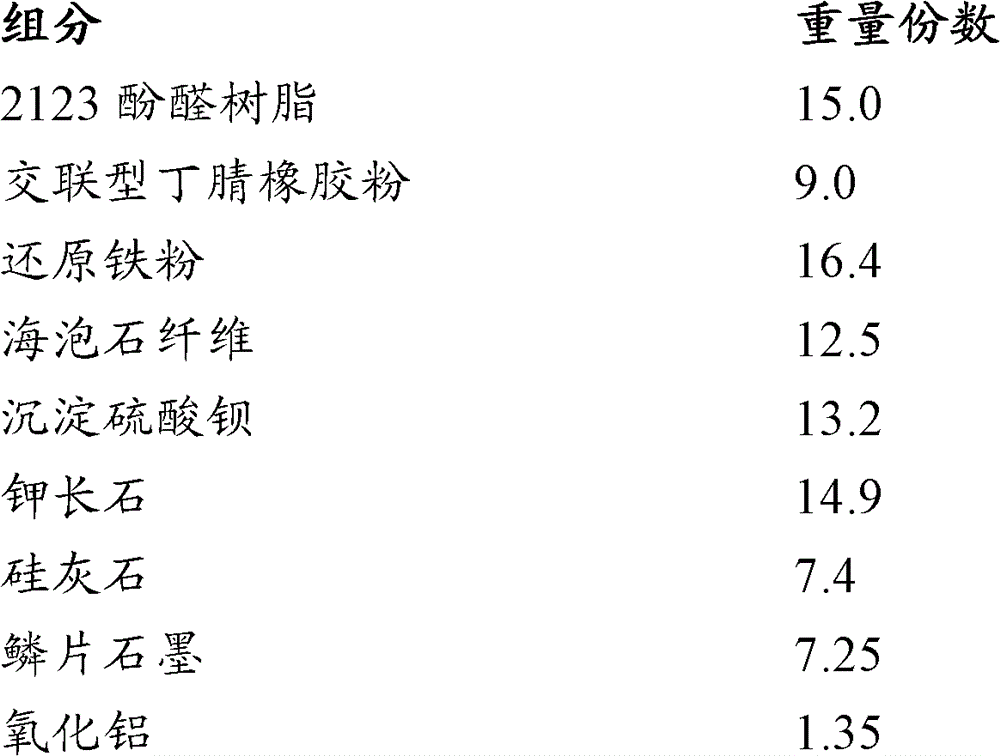

[0048] The components of the high-friction synthetic brake shoe and their proportions by weight are as follows:

[0049]

[0050] The specifications of the above raw materials are: 2123 phenolic resin: curing speed 60-90 seconds / 160°C, softening point 100-105°C, free phenol content 4%; nitrile rubber powder: cross-linked type, fineness 40 mesh; reduced iron Powder: iron content 98%, fineness 80 mesh; sepiolite fiber: MY-A type, Hebei Mingyang Company, fiber length 0.2-5mm, moisture content 3%, whiteness 80%, sand content 1%; Barium sulfate: white amorphous powder, barium sulfate content 99%, fineness above 200 mesh; wollastonite: light gray fibrous, aspect ratio 10:1, SiO 2 content of 51.75%, CaO content of 48.25%; potassium feldspar: fineness greater than 200 mesh, potassium oxide content of 8.9%; graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com