Method for preparing electronic grade tetramethylammonium hydroxide by continuous method

A tetramethylammonium hydroxide, electronic-grade technology, applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of pollution, consumption of silver oxide, inability to scale production, etc., and achieve high product purity and power utilization rate High and reduce the effect of industrial three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

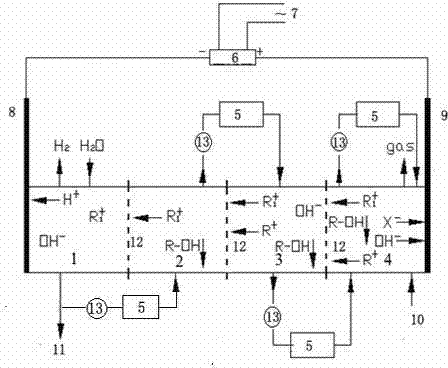

[0021] The electrode material of the anode plate 9 is titanium, the electrode material of the cathode plate 8 is nickel, the plate is coated with oxygen and chlorine evolution, and the current density is 1000 A / ㎡. The electrolyte in the two adjacent chambers of the cathode chamber 1, the first cathode intermediate chamber 2, the second cathode intermediate chamber 3, and the anode chamber 4 are all externally circulated by the circulation pump 13, and the anode chamber 4 itself uses the circulation pump 13. Carry out internal circulation. Concentration is the saline solution of 50% tetramethylammonium bicarbonate in the anode chamber 4, is the tetramethylammonium hydroxide that concentration is 20% in the second cathode intermediate chamber 3, is concentration in the first cathode intermediate chamber 2. 3% tetramethylammonium hydroxide, the concentration of 30% tetramethylammonium hydroxide in the cathode chamber 1, the current efficiency is 70%.

[0022] By connecting the c...

Embodiment 2

[0024] The electrode material of the anode plate 9 is titanium, the electrode material of the cathode plate 8 is graphite, the plate is coated with oxygen and chlorine evolution, and the current density is 1500 A / ㎡. The pump circulation mode of the electrolyte in each chamber is the same as that of Embodiment 1. Concentration is 40% tetramethylammonium bicarbonate solution in the anode chamber 4, concentration is 10% tetramethylammonium hydroxide in the second cathode intermediate chamber 3, and concentration is 10% in the first cathode intermediate chamber 2 Tetramethylammonium hydroxide, in the cathode compartment 1 is the tetramethylammonium hydroxide concentration of 15%, and the current efficiency is 90%.

[0025] Connecting the current between the two plates can continuously electrolyze and prepare electronic-grade tetramethylammonium hydroxide. The concentration of each metal ion in the prepared electronic-grade tetramethylammonium hydroxide is less than 10 ppb, and the...

Embodiment 3

[0027] The electrode material of the anode plate 9 is titanium, the electrode material of the cathode plate 8 is graphite, the plate is coated with oxygen and chlorine evolution, and the current density is 2000 A / ㎡. The pump circulation mode of the electrolyte in each chamber is the same as that of Embodiment 1. Concentration is 5% tetramethylammonium bicarbonate solution in the anode chamber 4, concentration is 1% tetramethylammonium hydroxide in the second cathode intermediate chamber 3, and concentration is 4% in the first cathode intermediate chamber 2 Tetramethylammonium hydroxide, the concentration is 5% tetramethylammonium hydroxide in the cathode chamber 1, and the current efficiency is 83%.

[0028] Connecting the current between the two plates can continuously electrolyze and prepare electronic grade tetramethylammonium hydroxide. The concentration of each metal ion in the prepared electronic grade tetramethylammonium hydroxide is less than 10 ppb (see Table 1), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com