Addition curing type silicon compound, optical element sealing material and semiconductor device

An addition-curing type, composition technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problem of not being able to fully meet the sulfidation resistance luminous efficiency, etc., and achieve excellent reliability and anti-sulfurization. Excellent performance and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Hereinafter, the present invention will be specifically described by showing preparation examples, examples, and comparative examples, but the present invention is not limited to the following examples.

[0103] In addition, in the following examples, the viscosity means the value measured at 25 degreeC using the rotational viscometer.

preparation example 1

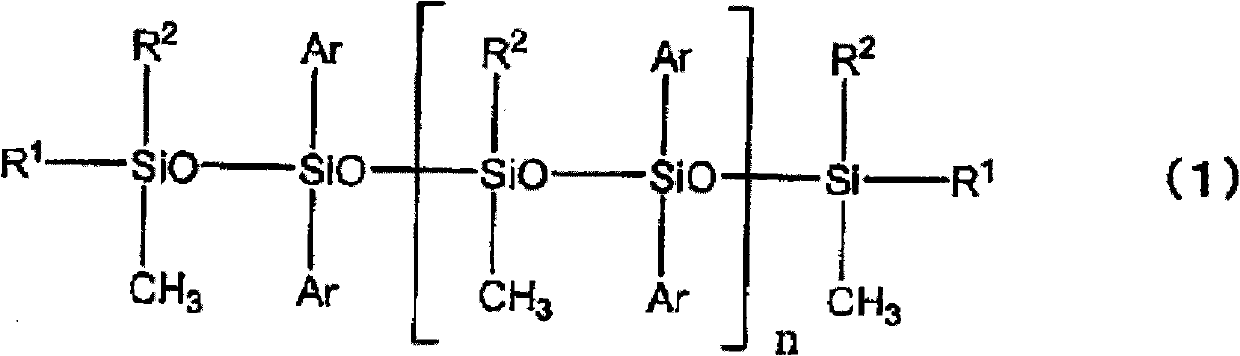

[0105] Uniformly mix 100 parts by mass of a compound represented by the following formula (hereinafter referred to as "compound A") (viscosity 2Pa.s); the viscosity is 0.02Pa.s, and the average composition formula HMe 2 SiO(MeHSiO) 2 (Ph 2 SiO) 2 SiMe 2 41 parts by mass of organohydrogenpolysiloxane represented by H; 0.14 parts by mass of toluene solution containing 1 mass % of chloroplatinic acid / 1,3-divinyltetramethyldisiloxane complex as platinum atom content; 0.05 parts by mass of ethynylcyclohexanol as a control agent; and 3 parts by mass of γ-glycidoxypropyltrimethoxysilane; prepare silicon composition (I). The silicon composition (I) was cured by heating at 150°C for 4 hours, and the hardness of Type A was 66.

[0106]

preparation example 2

[0108] Evenly mixed compound A26 mass parts; By average composition formula (PhSiO 3 / 2 ) 0.75 [(CH 2 =CH)Me 2 SiO 0.5 ] 0.25 The represented solid branched organopolysiloxane [the content of the vinyl group bonded to the silicon atom = 17 mol %, the phenyl group bonded to the silicon atom in all the organic groups bonded to the silicon atom Content ratio=50 mol%, the weight-average molecular weight=1600]74 mass parts of standard styrene conversion; By average composition formula HMe 2 SiO(Ph 2 SiO) 1 SiMe 2 32 parts by mass of organohydrogenpolysiloxane represented by H; 0.13 parts by mass of toluene solution containing 1 mass % of chloroplatinic acid / 1,3-divinyltetramethyldisiloxane complex as platinum atom content; acetylene 0.05 parts by mass of cyclohexyl alcohol; and, 3 parts by mass of γ-glycidoxypropyltrimethoxysilane; prepare the silicon composition (II). The silicon composition (II) was cured by heating at 150°C for 4 hours, and the hardness was 43 on Shore D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com