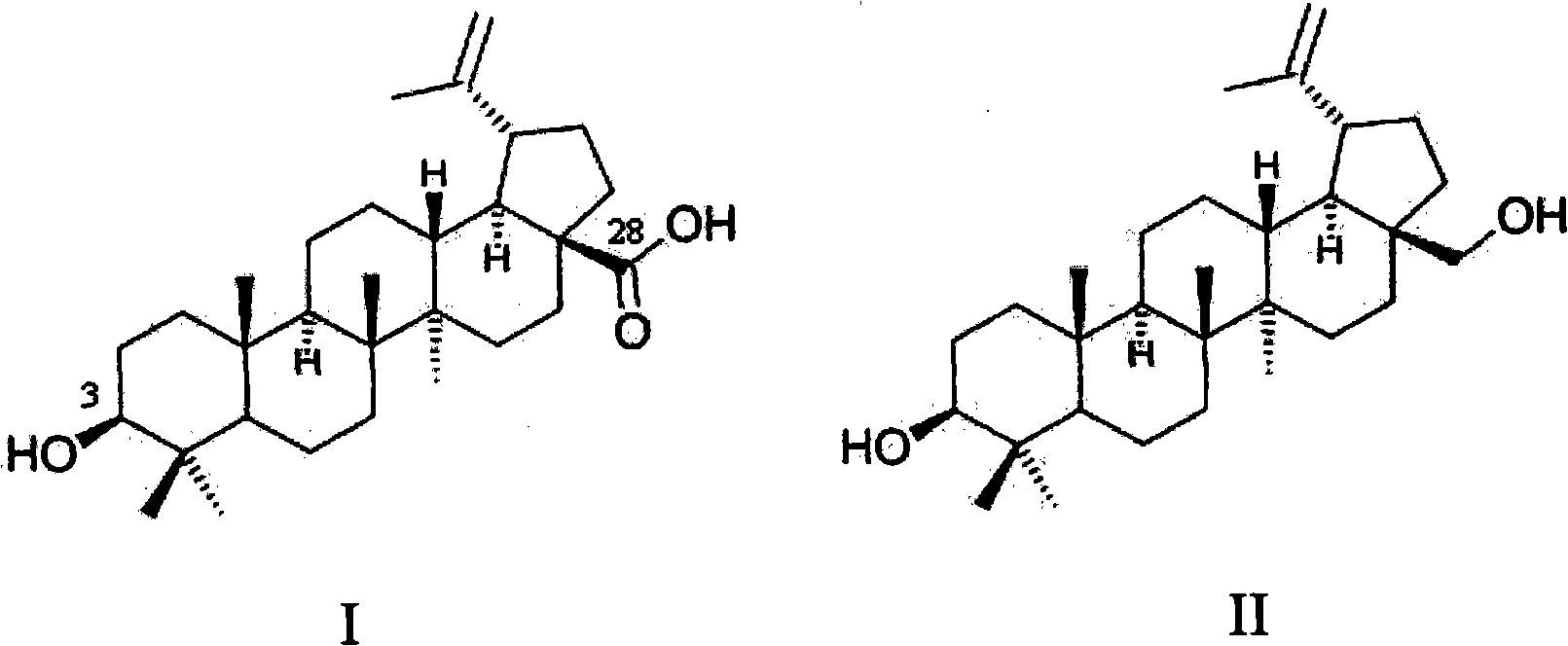

Preparation method for betulinic acid

A technology of betulinic acid and betulin, which is applied in the field of semi-synthesized betulinic acid from betulin, can solve the problems of difficult recovery of high boiling point solvents and solvents, and achieve the effects of easy product purification, short process route and simple treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of betulinic acid, using betulin as raw material, comprises the steps carried out in the following order:

[0025] (1) Preparation of crude betulinic acid by oxidation of betulin: dissolving betulin in a water-soluble organic solvent, adding 2,2,6,6-tetramethyl-1-piperidone, sodium bromide, and sodium acetate in sequence Aqueous solution, N-chlorophthalimide, stirred at 0-35°C for 0.5-2 hours, filtered after the reaction, acidified the filtrate with hydrochloric acid until the precipitate precipitated, filtered and washed the obtained precipitate, and dried naturally to obtain birch crude acid;

[0026] (2) Purify the crude betulinic acid to obtain the betulinic acid product: dissolve the crude betulinic acid obtained in step (1) in an organic solvent, add an aqueous solution of inorganic alkali and stir at 50-70°C for 0.5-2 hours, then filter and separate the liquids , the inorganic phase was acidified with hydrochloric acid until precipitation wa...

Embodiment 1

[0033] Dissolve 44.3 grams (0.1moL) betulin in 4430 milliliters of acetone, add 0.156 grams (0.001moL) 2,2,6,6-tetramethyl-1-piperidone, 0.515 grams (0.005moL ) sodium bromide, 4.5 milliliters of sodium acetate aqueous solution with a mass concentration of 15%, 45.5 grams (0.25 moL) of N-chlorophthalimide, stirred and reacted at 25 ° C for 2 hours, filtered, and added to the filtrate Add dilute hydrochloric acid to acidify to pH 3.5, filter, wash the precipitate with distilled water, and air-dry to obtain 41 g of crude betulinic acid. Dissolve the obtained crude betulinic acid in 2050 ml of cyclopentanone, add 41 ml of 30% aqueous sodium hydroxide solution, stir and react at 50°C for 2 hours, filter, add dilute hydrochloric acid to the filtrate to acidify to pH 2.5, and filter , the precipitate was washed with distilled water, air-dried, and recrystallized from methanol to obtain 22.4 grams of betulinic acid product with a purity of 95.9% and a yield of 47%.

Embodiment 2

[0035] Dissolve 44.3 grams (0.1moL) of betulin in 8860 milliliters of tetrahydrofuran, add 0.78 grams (0.005moL) of 2,2,6,6-tetramethyl-1-piperidone, 1.03 grams (0.01moL ) sodium bromide, 10% sodium acetate aqueous solution with a mass concentration of 10 milliliters, 36.4 grams (0.2 moL) of N-chlorophthalimide, stirred and reacted at 35°C for 1 hour and then filtered, and dripped in the filtrate Add dilute hydrochloric acid to acidify to pH 2.5, filter, wash the precipitate with distilled water, and air-dry to obtain 43.9 g of crude betulinic acid. Dissolve the crude betulinic acid obtained in 4390 ml of cyclopentanone, add 200 ml of 30% potassium hydroxide aqueous solution, stir and react at 55°C for 1 hour, filter, add dilute hydrochloric acid to the filtrate to acidify to pH 2.5, and filter , the precipitate was washed with distilled water, air-dried, and recrystallized from methanol to obtain 23.6 grams of betulinic acid product with a purity of 92.9% and a yield of 48%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com