High-oil-content seed kernel cold-pressing oil-making machine

A kind of benevolent cooling and oil machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of small production scale, inability to process oil, dark color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

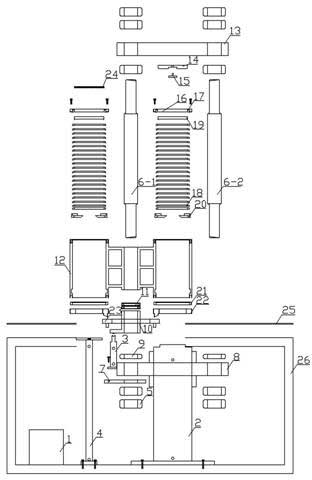

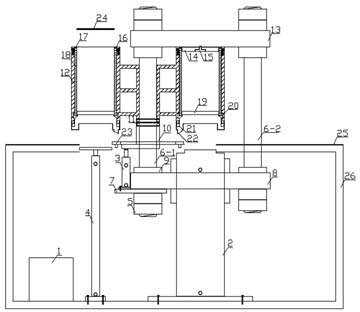

[0024] As shown in the figure, the present invention is divided into a hydraulic power system and a pressing oil system. The hydraulic power system includes: hydraulic pump station 1, oil pressing power hydraulic cylinder 2, lifting and sealing hydraulic cylinder 3, loading and unloading hydraulic cylinder 4; oil pressing system including: press tension column shaft nut 5, press tension column Shaft 6-1, press tension column shaft 6-2, pressure-bearing lifting bottom support 7, pressure-bearing power hydraulic cylinder lug 8, column shaft adjusting pad 9, pressure-bearing lifting arm guide sleeve 10, double pressure bearing 11, Press cylinder body 12, pressure stop top plate 13, positioning mound 14, positioning mound bolt 15, press cylinder flange 16, sealing strip 17, flow aid angle press ring 18, pressure sliding top plate 19, press ring key 20, Oil collecting groove lock channel 21, cylinder block oil collecting groove 22, mutual biting half-ring oil guide groove 23, high p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com