Microbe and farm chemical composite bactericide and preparation method thereof

A technology of microbial pesticides and compound fungicides, applied in the directions of botanical equipment and methods, fungicides, biocides, etc., can solve the problems of affecting the habitat of crops and enhancing the drug resistance of bacteria, and achieves simple preparation method and production cost. Low, delayed enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

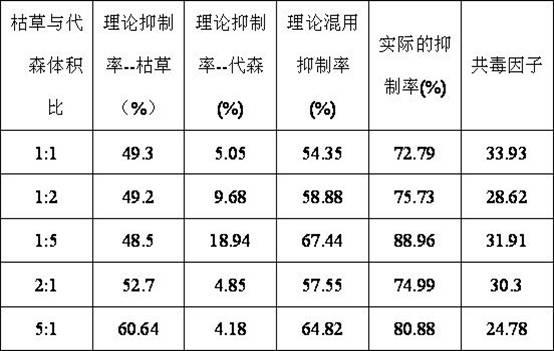

Image

Examples

Embodiment 1

[0075] (1) Inoculate the Bacillus subtilis BAB-1 strain (preservation number: CGMCCNo.2099) into NB liquid medium. After 12 hours of cultivation, the strain reaches the logarithmic growth phase, and transfer it to 50mL of In PB liquid medium (contain beef extract 5g, NaCl 5g, peptone 10g, 1000mL water, pH 7.0-7.2 per liter), after 38 hours of cultivation, 95% of the bacteria formed spores, and the fermentation liquid of Bacillus subtilis was obtained. Add β-cyclodextrin with 10% of the mass of the fermentation liquid to the above fermentation liquid, and spray dry to obtain the original powder of Bacillus subtilis, the number of live bacteria in the original powder is 15-20 billion / g;

[0076] (2) Add mancozeb according to the mass ratio of the original powder: mancozeb=95:5, and mix to obtain effective active ingredients;

[0077] (3) Weigh each component according to the following parts by weight, and mix evenly to obtain a mixed powder:

[0078] 10 active ingredients

[0...

Embodiment 2

[0084] (1) Inoculate the Bacillus subtilis BS-03 strain (preservation number: CGMCCNo.3038) into the NB medium. After 12 hours of cultivation, the strain reaches the logarithmic growth phase, and transfer it to 50 mL of PB with a 5% inoculation amount. In the liquid culture medium (containing beef extract 5g, NaCl 5g, peptone 10g, 1000mL water, pH7.0-7.2 per liter), after 38 hours of cultivation, 95% of the bacteria formed spores to obtain the fermentation liquid of Bacillus subtilis. Add β-cyclodextrin with 10% of the mass of the fermentation broth to the fermentation broth, and spray dry to obtain the original powder of Bacillus subtilis, the number of live bacteria in the original powder is 15-20 billion / g;

[0085] (2) Add mancozeb according to the mass ratio of the original powder: mancozeb=99:1, and mix to obtain effective active ingredients;

[0086] (3) Weigh each component according to the following parts by weight, and mix evenly to obtain a mixed powder:

[0087] A...

Embodiment 3

[0093] (1) Inoculate the Bacillus subtilis sf-628 strain (preservation number: CGMCCNo.1772) into the NB medium. After 12 hours of cultivation, the strain reaches the logarithmic growth phase, and transfer it to 50 mL of PB with a 5% inoculation amount. In the liquid culture medium (containing beef extract 5g, NaCl 5g, peptone 10g, 1000mL water, pH7.0-7.2 per liter), after 38 hours of cultivation, 95% of the bacteria formed spores to obtain the fermentation liquid of Bacillus subtilis. Add β-cyclodextrin with 10% of the mass of the fermentation broth to the fermentation broth, and spray dry to obtain the original powder of Bacillus subtilis, the number of live bacteria in the original powder is 15-20 billion / g;

[0094] (2) Add mancozeb according to the mass ratio of the original powder: mancozeb=97:3, and mix to obtain effective active ingredients;

[0095] (3) Weigh each component according to the following parts by weight, and mix evenly to obtain a mixed powder:

[0096] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com