Integrated design of device with three-dimensional all-medium non-resonant metamaterial structure and manufacturing process

A manufacturing process and metamaterial technology, applied in the field of integrated design and manufacturing process of three-dimensional all-dielectric non-resonant metamaterial structure, to achieve low loss and easy three-dimensional expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

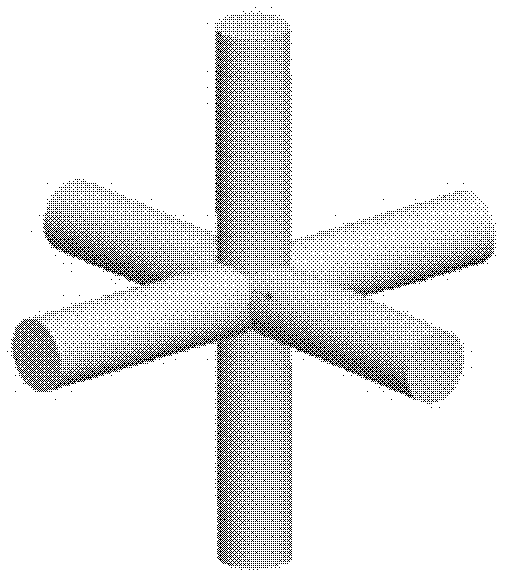

[0039] Using cross column structure (refer to figure 1 ) to design and manufacture the stealth carpet for the basic micro unit, specifically including the following steps:

[0040] 1) The structure of the metamaterial structural device is a stealth carpet, and the size design requirements: the macro dimension is 125mm long, 48mm high, and 9mm thick, and the invisible area is designed to be an isosceles triangle with a length of 125mm and a height of 13mm; Design, obtain its external contour model;

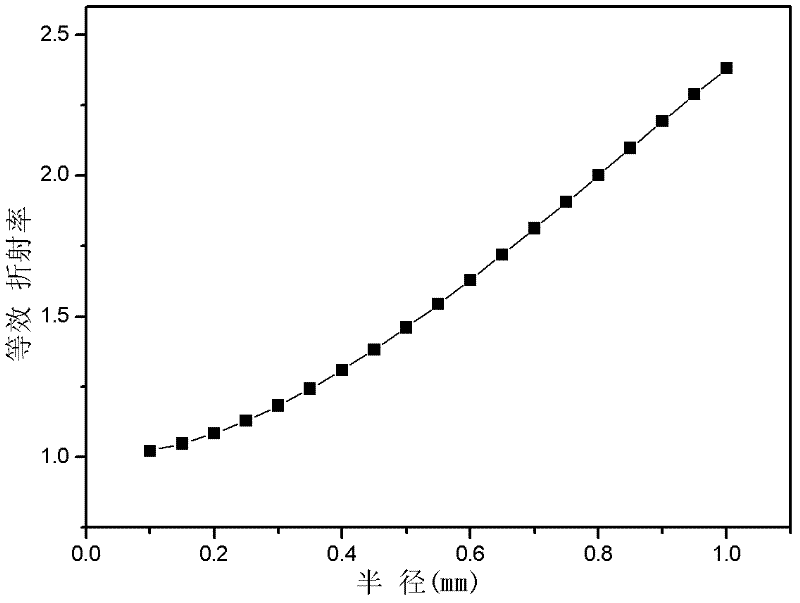

[0041] 2) According to the macroscopic shape structure and size of the invisible carpet designed in step 1), the spatial distribution of the refractive index of the invisible area of the invisible carpet is calculated by using the transformation optics principle and the quasi-conformal mapping theory. The specific spatial distribution of the refractive index of the invisible area is as follows Formula to calculate: n 2 =ε=1 / det(A);

[0042] Among them, n is the refractive inde...

Embodiment 2

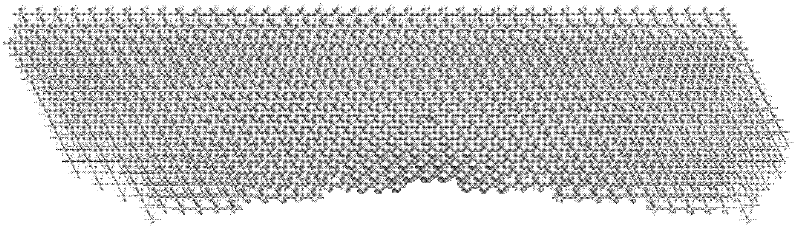

[0049] Using diamond photonic crystal structure (refer to Figure 4 ) to design and manufacture the stealth carpet for the basic micro unit, specifically including the following steps:

[0050] 1) The structure of the metamaterial structural device is a stealth carpet, and the size design requirements: the macro dimension is 250mm long, 96mm high, and 6mm thick, and the invisible area is designed to be an isosceles triangle with a length of 250mm and a height of 26mm; Design, obtain its external contour model;

[0051] 2) According to the macroscopic shape structure and size of the invisible carpet designed in step 1), the spatial distribution of the refractive index of the invisible area of the invisible carpet is calculated by using the transformation optics principle and the quasi-conformal mapping theory. The specific spatial distribution of the refractive index of the invisible area is as follows Formula to calculate: n 2 =ε=1 / det(A);

[0052] Among them, n is the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com