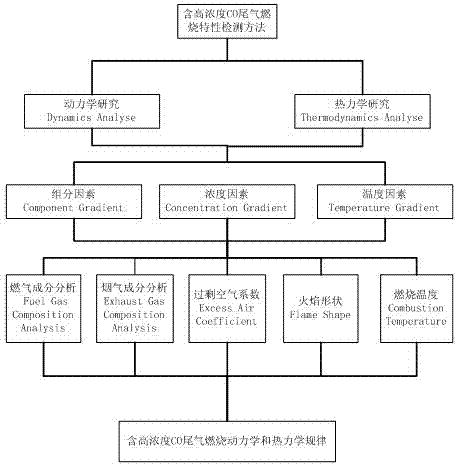

Device and method for detecting combustion characteristic of tail gas containing high-concentration CO

A technology for combustion characteristics and detection devices, which is applied in the field of combustion characteristics detection devices for tail gas containing high concentrations of CO, can solve the problems of yellow phosphorus tail gas combustion characteristics that have not been reported, the utilization rate is less than 40%, and the exhaust gas is ignited and vented. Simple, good stability and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

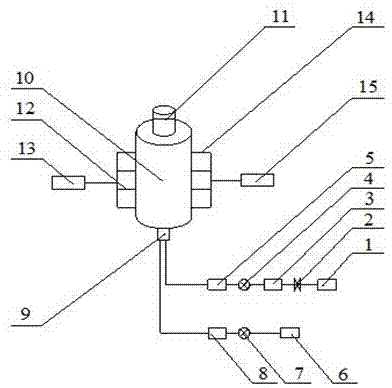

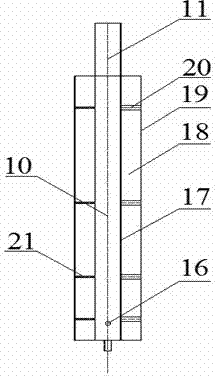

Embodiment 1

[0033] Combustion characteristics test of yellow phosphorus tail gas: insert the electronic ignition gun into the ignition hole, turn on the electronic ignition gun, and open the yellow phosphorus tail gas flow regulating valve at the same time, the initial temperature of the yellow phosphorus tail gas is 106°C, ignite the yellow phosphorus tail gas, and adjust it through the flow regulating valve The flow rate is 1.0m 3 / h, plug the ignition hole with thermal insulation material to prevent air from entering through the ignition hole; open the air flow regulating valve, and adjust the air flow so that the excess air coefficient is 1.00, 1.10, 1.20, 1.30; the ignited gas is in the combustion chamber For combustion, use thermocouples to extend into the thermocouple sockets on the four combustion chambers to collect temperature data respectively. The positions of the four thermocouple interfaces from the bottom of the combustion chamber are 100 mm, 300 mm, 650 mm, and 1100 mm resp...

Embodiment 2

[0037] Put the electronic ignition gun into the ignition air, turn on the electronic ignition gun, and open the yellow phosphorus tail gas flow regulating valve at the same time, the temperature of the yellow phosphorus tail gas is 110°C, ignite the yellow phosphorus tail gas, and adjust the flow rate to 1.0, 1.1, 1.2, 1.3 through the flow regulating valve , 1.4m 3 / h. Plug the ignition hole with thermal insulation material to prevent air from entering through the ignition hole. Open the air flow regulating valve and adjust the excess air coefficient to 1.3 when the corresponding gas flow is reached. The ignited gas is carried out in the combustion chamber, and thermocouples are inserted into the thermocouple sockets on the four combustion chambers to collect temperature data. The positions of the four thermocouple interfaces from the bottom of the combustion chamber are 100mm, 300 mm, 650 mm, and 1100 mm respectively, and the distance from the center line of the combustion ...

Embodiment 3

[0040] Put the electronic ignition gun into the ignition air, turn on the electronic ignition gun, and open the yellow phosphorus tail gas flow regulating valve at the same time. The temperature of the yellow phosphorus tail gas is 78°C, ignite the yellow phosphorus tail gas, and adjust the flow rate to 1.0m through the flow regulating valve. 3 / h. Plug the ignition hole with thermal insulation material to prevent air from entering through the ignition hole. Open the air flow regulating valve, and adjust the excess air coefficient of the air flow to 0.8, 0.9, 1.0, 1.1, 1.2, 1.3, 1.4 respectively. The ignited gas is carried out in the combustion chamber, and the flue gas composition collector is used to penetrate into the flue gas composition collection hole at a height of 1100mm to detect the flue gas composition. For the flue gas composition data, see Figure 7 .

[0041] Figure 7 O in the smoke composition of yellow phosphorus tail gas combustion 2 , CO, CO 2 The chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com