Heat bridge resistant complex radiation heat insulation film energy-saving decorative system and construction method thereof

A composite radiation and heat insulation film technology, which is applied in covering/lining, building, building structure, etc., can solve the problems of insufficient combination of heat insulation decoration system, large space occupation, and low energy saving efficiency, so as to save materials and reduce Energy consumption and the effect of reducing building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

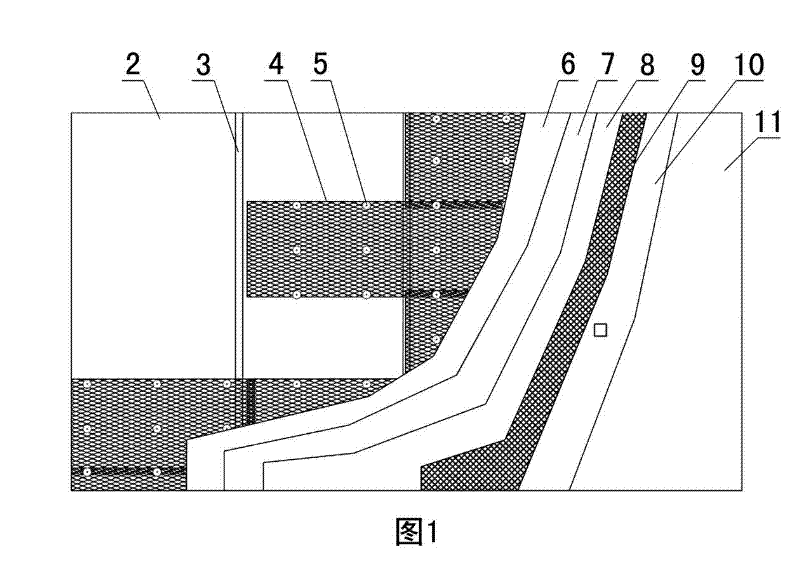

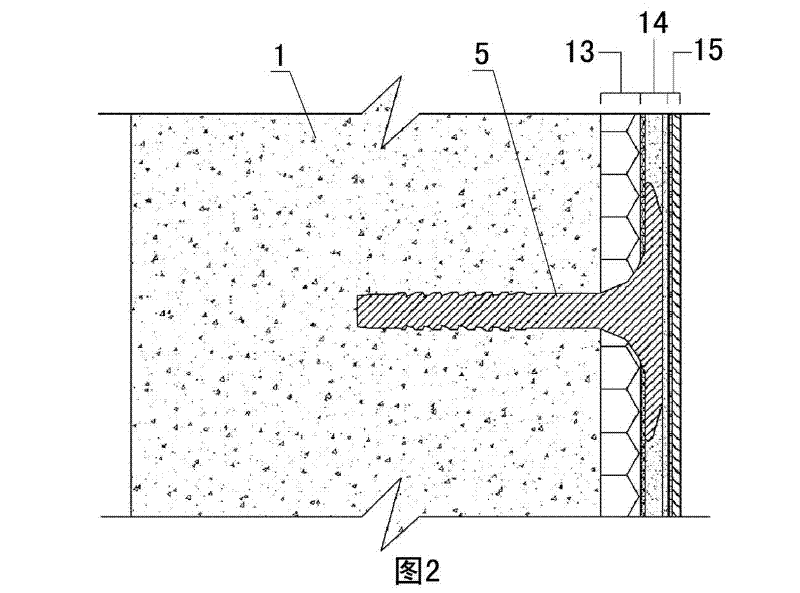

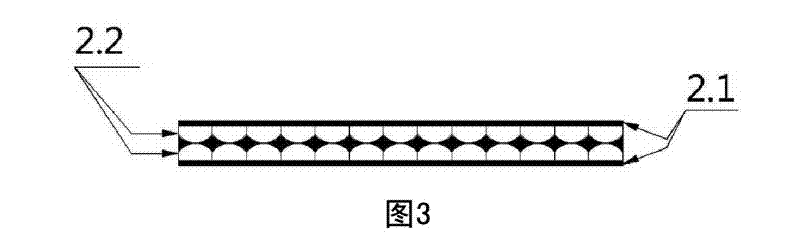

[0047] Examples see figure 1 , figure 2 As shown, the energy-saving decoration system of this heat-resisting bridge composite radiation heat-insulating film is internal heat preservation, and includes an anti-radiation heat-insulation layer 13 attached to the building wall 1, and the anti-radiation heat-insulation layer consists of pieces of radiation heat insulation The film 2 is composed of the aluminum foil adhesive tape 3 arranged between the gaps of two adjacent radiant heat insulation films.

[0048] The outer side of the anti-radiation heat insulation layer 13 is provided with an adhesive layer 14, and the adhesive layer is bonded by the expanded steel mesh 4 attached to the outer side of the anti-radiation heat insulation layer and the first layer solidified with the expanded steel mesh. The adhesive polymer mortar 6 and the second layer of adhesive polymer mortar 7 attached to the outside of the first layer of adhesive polymer mortar 6 are composed of the first lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com