High-strength high-tenacity rare earth-containing steel material for Z-type steels

A high-toughness, high-strength technology, applied in the field of metal materials produced in the metallurgical industry, can solve problems such as inability to perform heat treatment, hidden dangers in the use of carriages, and decreased toughness, and achieve the effects of improving labor productivity, reducing the weight of the car body, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

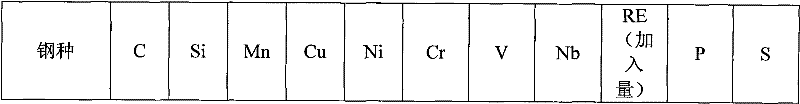

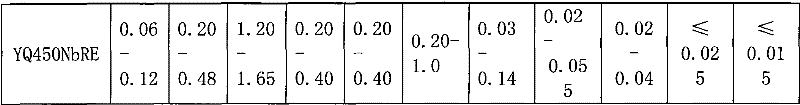

[0009] After special research by scientific and technical personnel and tests in a 25kg vacuum induction furnace, the composition range of molten steel was designed as shown in Table 1, and the name of the steel grade was YQ450NbRE.

[0010] Table 1 Composition requirements of YQ450NbRE special steel for B-shaped steel, w%

[0011]

[0012]

[0013] The technological process is: 100t converter smelting→100t L F furnace refining→continuous casting (the billet specification is 319mm×410mm).

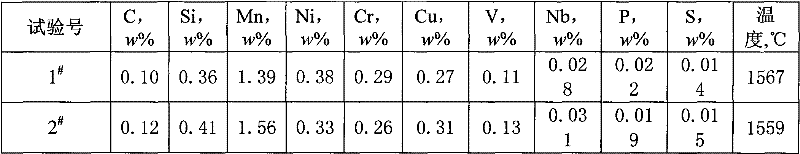

[0014] Two heats of steel were produced in industrial trial production, and the specific process parameters were controlled as follows:

[0015] 1) Converter production

[0016] The carbon content, phosphorus content and tapping temperature of the molten steel at the end of the converter are shown in Table 2.

[0017] Table 2 Composition and temperature of YQ450NbRE furnace-tapped steel for B-shaped steel

[0018] Test No.

Tapping temperature, ℃

Tapping carbon cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com