Protective plate-free steel band water-cooling quenching device

A quenching device and water cooling technology, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of increasing the cost of steel strip quenching, troublesome operation of workers, and reducing the thermal conductivity of the pressing plate, so as to improve the surface quality and hardenability , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

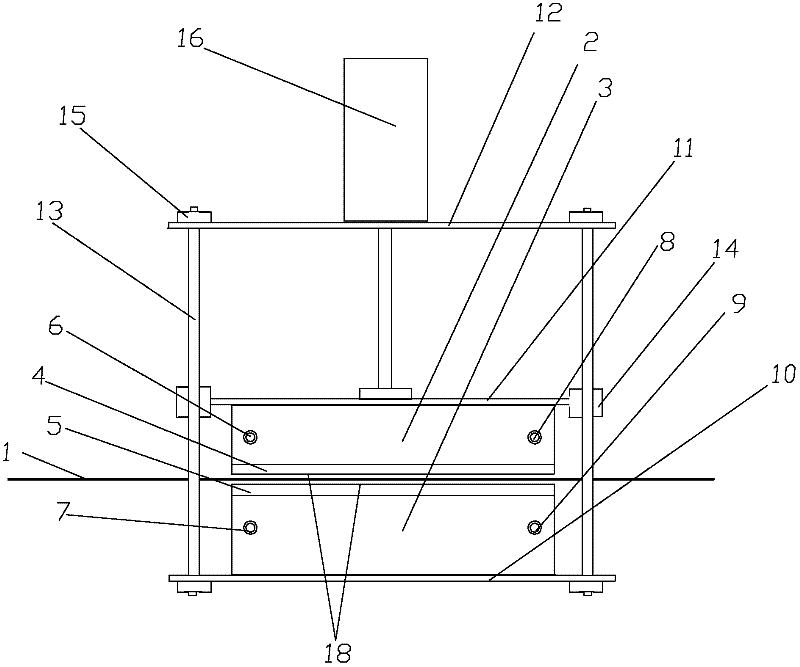

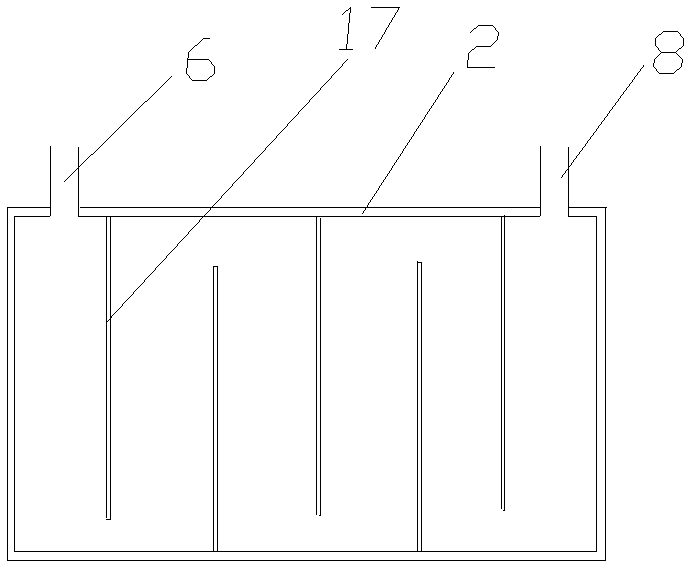

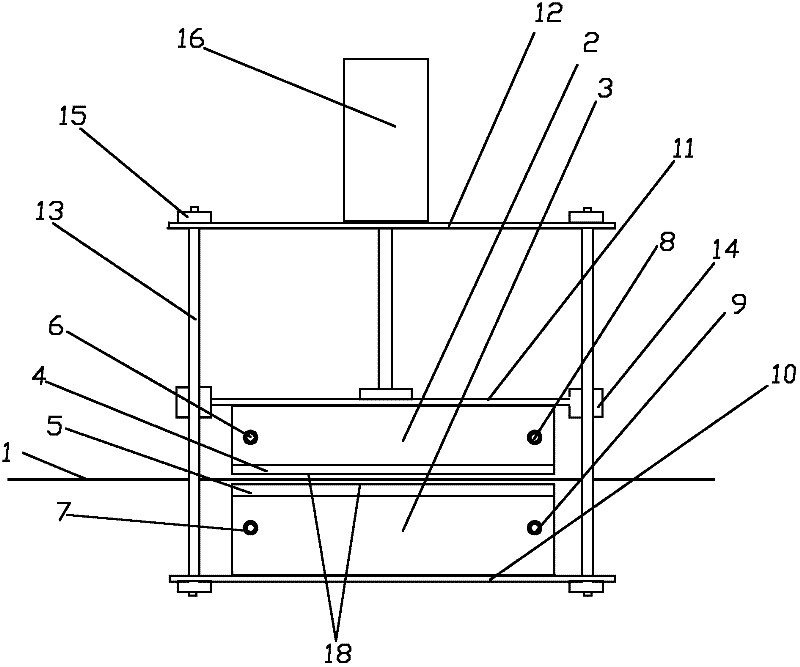

[0016] Such as figure 1 and figure 2 As shown, a steel strip water cooling and quenching device without a protective plate includes an upper fixed plate 12, a lower fixed plate 10, a column 13 fixed between the upper fixed plate 12 and the lower fixed plate 10, and the upper fixed plate 12 An upper water tank 2 is arranged on the top, an upper pressing plate 4 is provided at the bottom of the upper water tank 2, a lower water tank 3 is arranged on the lower fixing plate 10, and a lower pressing plate 5 is arranged on the top of the lower water tank 3, and the upper pressing plate 4 and A steel strip 1 that is cooled and quenched through the heat conduction of the upper press plate 4 and the lower press plate 5 is passed between the lower press plates 5 , and the surfaces of the upper press plate 4 and the lower press plate 5 are both electroplated with a hard chromium layer 18 . The material of the upper pressing plate 4 and the lower pressing plate 5 is 65Mn steel plate que...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com