Feeding pipe of reactor for continuous polymerization production of spandex

A feeding pipe and reactor technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as short intervals of cleaning equipment, adverse effects of production, pressure fluctuations, etc., and achieve continuous operation Time extension, extended cleaning interval, reliable and safe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] see figure 1 , figure 1 It is a schematic longitudinal section view of the feed pipe of the reactor produced by the continuous polymerization of spandex in the present invention. Depend on figure 1 It can be seen that the reactor feed pipe produced by the continuous polymerization of spandex in the present invention includes a feed pipe body 1, a mixed amine feed pipe 2, a prepolymer feed pipe 3, an end flange cover 4 and a manual scraper system 5 .

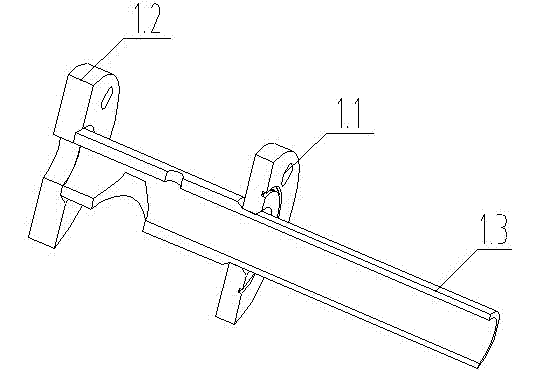

[0023] see figure 2 , figure 2 It is a schematic diagram of the longitudinal section of the feed pipe body of the present invention. Depend on figure 2 It can be seen that the feed pipe body 1 includes a main feed pipe 1.3, a first flange 1.1 and a second flange 1.2, and the first flange 1.1 and the second flange 1.2 are installed on the main feed pipe 1.3 respectively. middle and one end.

[0024] see image 3 , image 3 It is a schematic diagram of the longitudinal section of the mixed amine feeding pipe of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com