Internal curing material of high-performance concrete and preparation method thereof

A technology of high-performance concrete and super-absorbent materials, applied in the field of building materials, to achieve the effect of strong applicability, no impact on strength and durability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

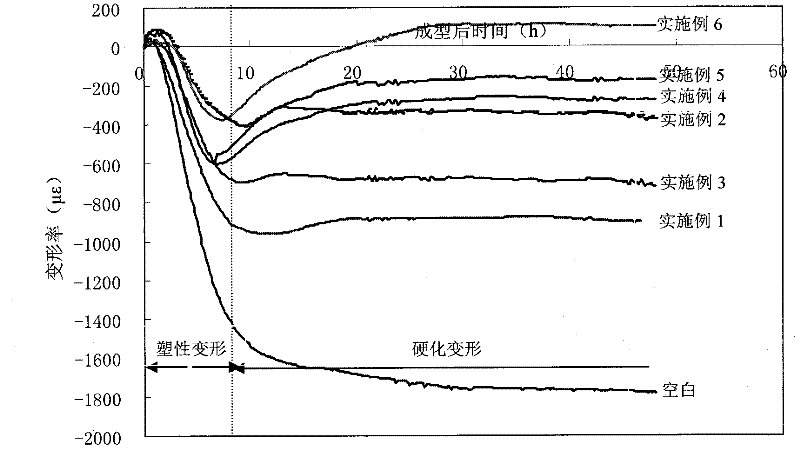

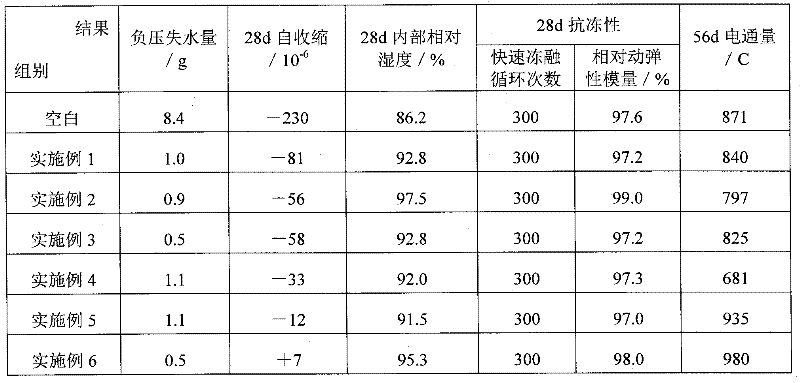

Examples

Embodiment 1

[0056] A high-performance concrete internal curing material, the internal curing material includes the following components and contents (parts by mass):

[0057] Expander 100;

[0058] Organic super absorbent material 1.25;

[0059] Inorganic water-absorbing material 10;

[0060] Water retaining agent 0.25;

[0061] Filler 10.

[0062] A method for preparing a high-performance concrete interior curing material, the method comprising the following steps:

[0063] (1) Add 6wt% acrylic acid to the three-necked flask under ice-water bath conditions, and drop 30wt% mass concentration of 25% sodium hydroxide solution under stirring, after that, add 18wt% acrylamide and 20wt% mass concentration of 0.1 % N, N'-methylenebisacrylamide, stir evenly, put the mixed solution in a constant temperature water bath at 35°C, keep it under nitrogen for 2min, add 26wt% ammonium persulfate-sodium sulfite with a mass concentration of 0.5%, and stir After reacting for a period of time, the reac...

Embodiment 2

[0066] A high-performance concrete internal curing material, the internal curing material includes the following components and contents (parts by mass):

[0067] Expander 100;

[0068] Organic superabsorbent material 2.5;

[0069] Inorganic water-absorbing material 10;

[0070] Water retaining agent 0.25;

[0071] Filler 10.

[0072] A method for preparing a high-performance concrete interior curing material, the method comprising the following steps:

[0073] (1) Add 6wt% acrylic acid to the three-necked flask under ice-water bath conditions, and drop 30wt% mass concentration of 25% sodium hydroxide solution under stirring, after that, add 18wt% acrylamide and 20wt% mass concentration of 0.1 % N, N'-methylenebisacrylamide, stir evenly, put the mixed solution in a constant temperature water bath at 35°C, keep it under nitrogen for 2min, add 26wt% ammonium persulfate-sodium sulfite with a mass concentration of 0.5%, and stir After reacting for a period of time, the reacti...

Embodiment 3

[0076] A high-performance concrete internal curing material, the internal curing material includes the following components and contents (parts by mass):

[0077] Expander 100;

[0078] Organic superabsorbent material 2.5;

[0079] Inorganic water-absorbing material 10;

[0080] Water retaining agent 0.375;

[0081] Filler 10.

[0082] A method for preparing a high-performance concrete interior curing material, the method comprising the following steps:

[0083] (1) Add 6wt% acrylic acid to the three-necked flask under ice-water bath conditions, and drop 30wt% mass concentration of 25% sodium hydroxide solution under stirring, after that, add 18wt% acrylamide and 20wt% mass concentration of 0.1 % N, N'-methylenebisacrylamide, stir evenly, put the mixed solution in a constant temperature water bath at 35°C, keep it under nitrogen for 2min, add 26wt% ammonium persulfate-sodium sulfite with a mass concentration of 0.5%, and stir After reacting for a period of time, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com