Dust catcher for belt conveyor with large inclined angle

A technology of large inclination and belt conveyor, applied in the field of dust collectors, can solve the problems of reduced air extraction efficiency, blockage of dust removal pipes, flying dust at dust points, etc., and achieves the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

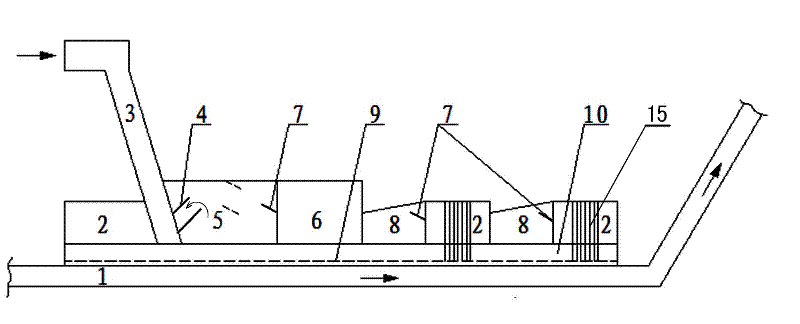

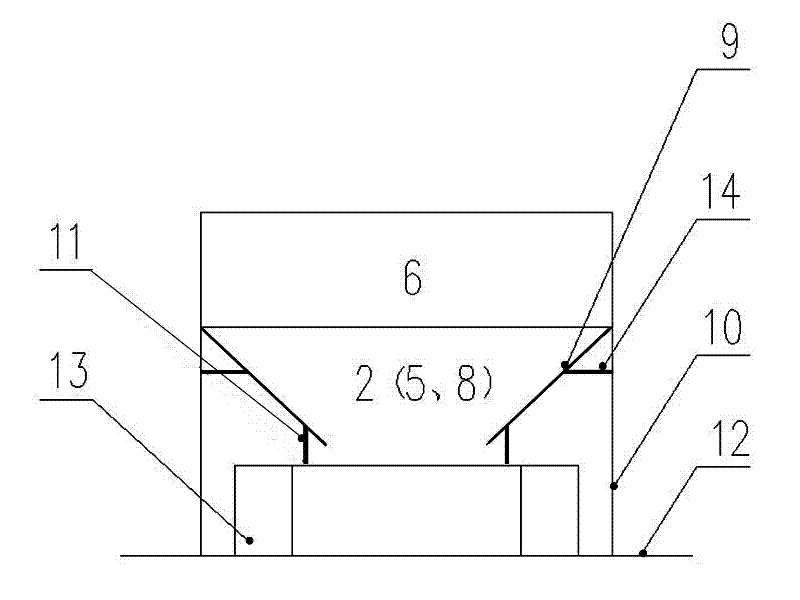

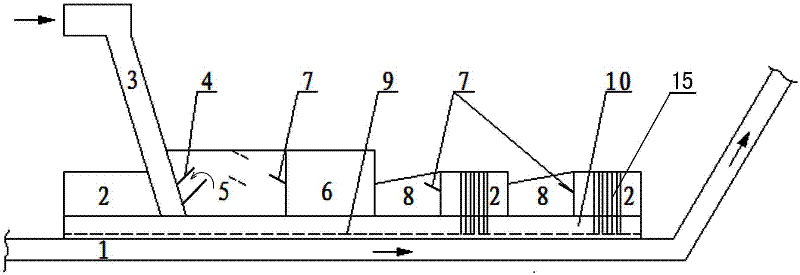

[0020] Example: see figure 1 , 2 , the head of the material-receiving flat section of the large-inclination belt conveyor 1 is sealed with a sealed chamber 2, and the high-efficiency settling chamber 5, dust filter 6, circulation separation chamber 8 and sealed chamber 2 are arranged in sequence after the station of the blanking pipe 3, The upper part of the high-efficiency settling chamber 5 and the circulation separation chamber 8 is provided with a baffle plate 7, the lower part of the drop pipe 3 is provided with an air flow balance pipe 4 communicating with the high-efficiency settling chamber 5, the high-efficiency settling chamber 5, the dust filter 6, and the circulation separation chamber 8 and the dust removal facilities of the sealed chamber 2 are connected into one body through the side board 10, and the inner wall of the side board 10 is provided with two deflectors 9, the deflectors are fixed on the upper end of the side board 10 by the bracket 14, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com