Impeller type vacuum quantitative packaging machine

A quantitative packaging, impeller-type technology, applied in the direction of packaging, packaging, transportation and packaging under vacuum/special atmosphere, can solve the problems of unsatisfactory packaging reliability and accuracy, interruption of filling operations, insufficient filling of packaging bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

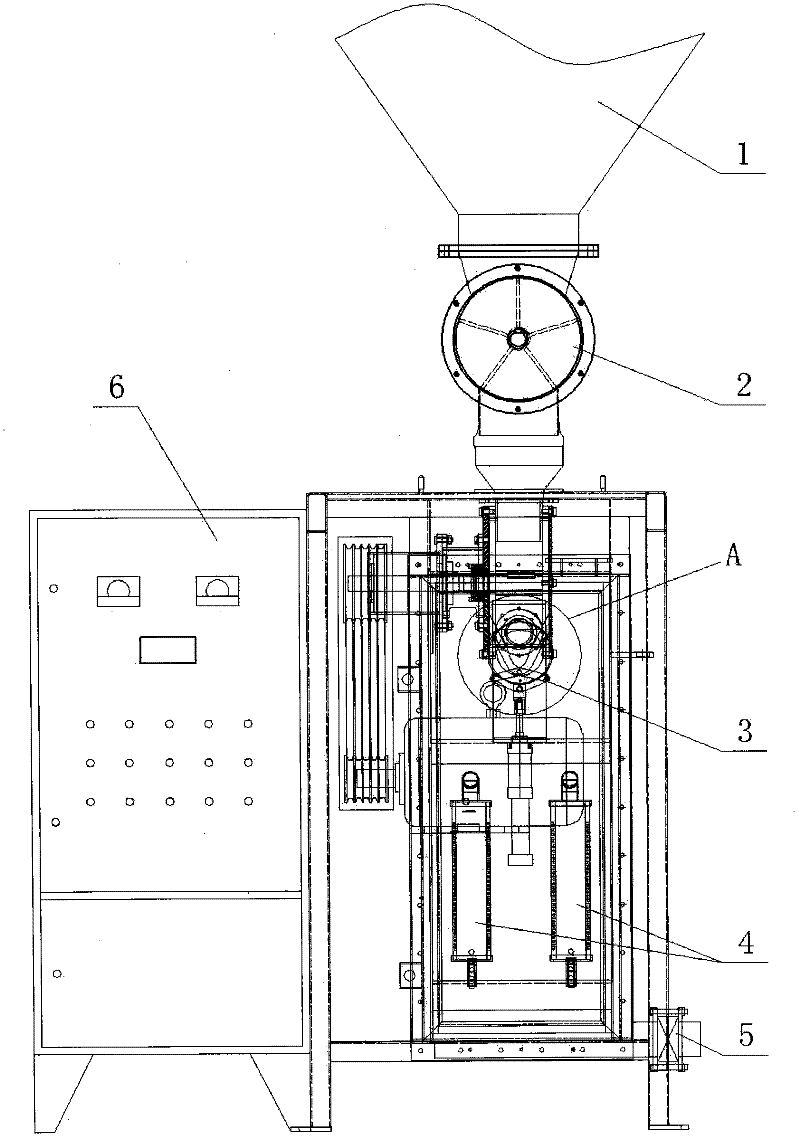

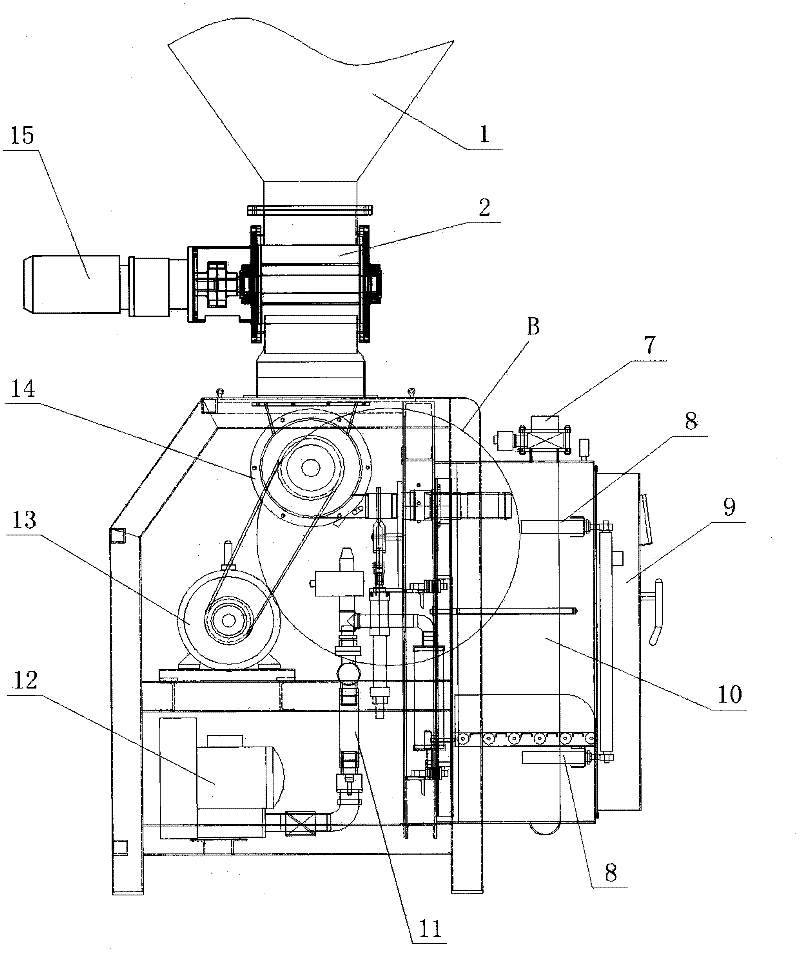

[0021] Such as figure 1 , image 3 As shown, an impeller type vacuum quantitative packaging machine of the present invention is provided with a star-shaped feeder 2 at the lower part of the feed bin 1, an impeller bin 14 is arranged at the lower part of the star-shaped feeder 2, and an impeller is arranged in the impeller bin 14. ; A vacuum chamber 10 is provided on the front side of the packaging machine frame.

[0022] Preferably, the impeller can be a vertical impeller or a horizontal impeller, the blades are fixed on the driving wheel by bolts, and the blades can be replaced.

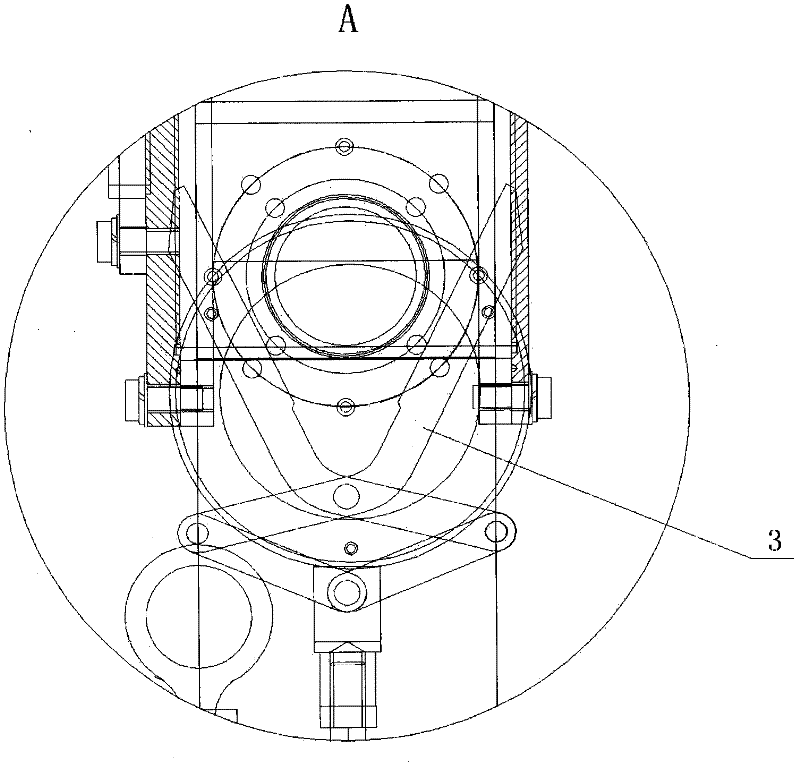

[0023] Such as figure 1 , image 3 , Figure 4 As shown, further, the bottom of the impeller chamber 14 is provided with a discharge port, the discharge port is connected to the buffer pipe of the vacuum chamber 10, and a scissor valve 3 is arranged at the discharge port, betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com