Foam concrete block cutting production line

A foamed concrete and production line technology, which is applied to the field of a complete set of cutting production lines for cutting foamed concrete blank blocks, can solve the problems of complex structure and operation of the feeding alignment mechanism, difficult to guarantee the quality of product segmentation, large segmentation errors, etc., and achieves waste products. The effect of low rate, reduced floor space and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

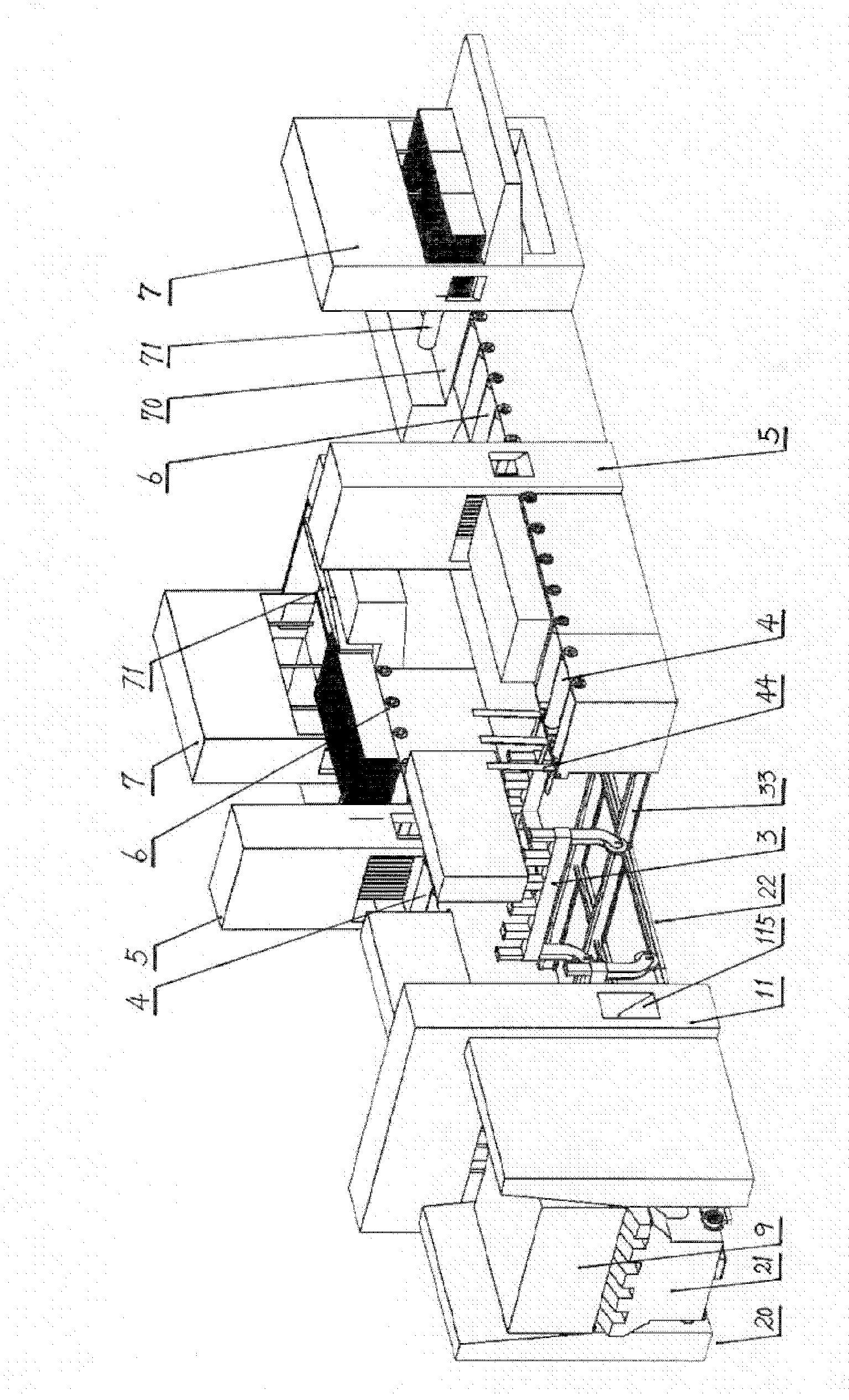

[0021] The following will be Figure 13 The general size shown is 1535mm×1535mm×750mm and the cutting steps are divided into a product with a length of 500mm×width 300mm×thickness as an example. The technical solution of the foamed concrete block cutting production line of the present invention is explained in detail. The dimensions in the thickness direction are usually It is determined by the user.

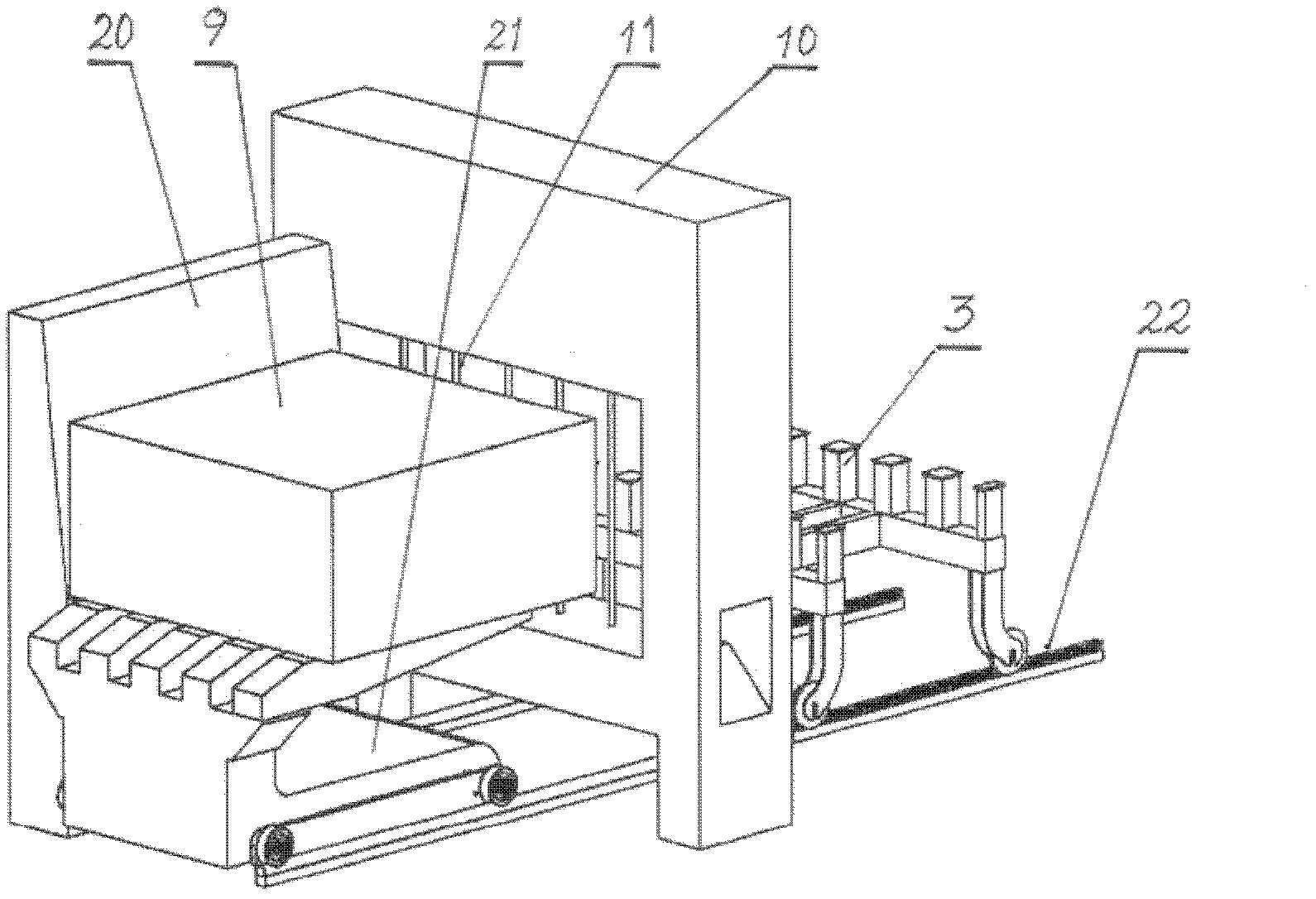

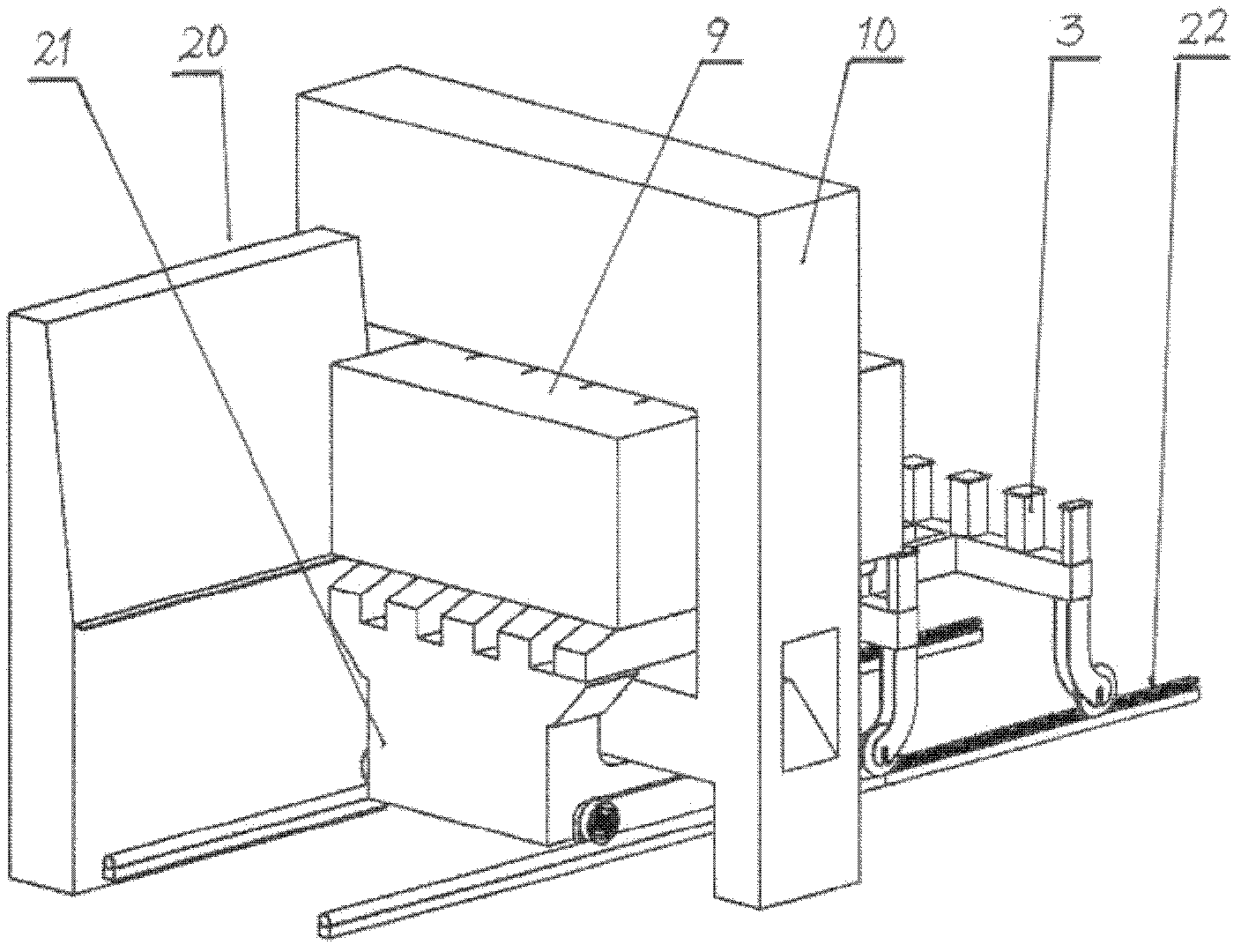

[0022] The foamed concrete block cutting production line disclosed in the patent application of the present invention includes a first cutting machine and its feeding mechanism, a batching car, a middle section conveying roller, a second cutting machine, a non-section conveying roller and a third cutting machine. The structure of each section is as follows:

[0023] The feeding mechanism includes a calibrated feeding channel 20 and a feeding car part arranged in the calibrated feeding channel 20. The feeding car part includes a feeding track 22 and a feeding cart 21 running along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com