Digital-display high-shear dispersion and emulsification machine used for laboratories

A high-shear, laboratory technology, used in mixers, mixer accessories, chemical instruments and methods, etc., can solve problems such as inconvenient adjustment of rotation speed, inconvenience for operators to obtain rotation speed intuitively, and inconvenient recording of experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

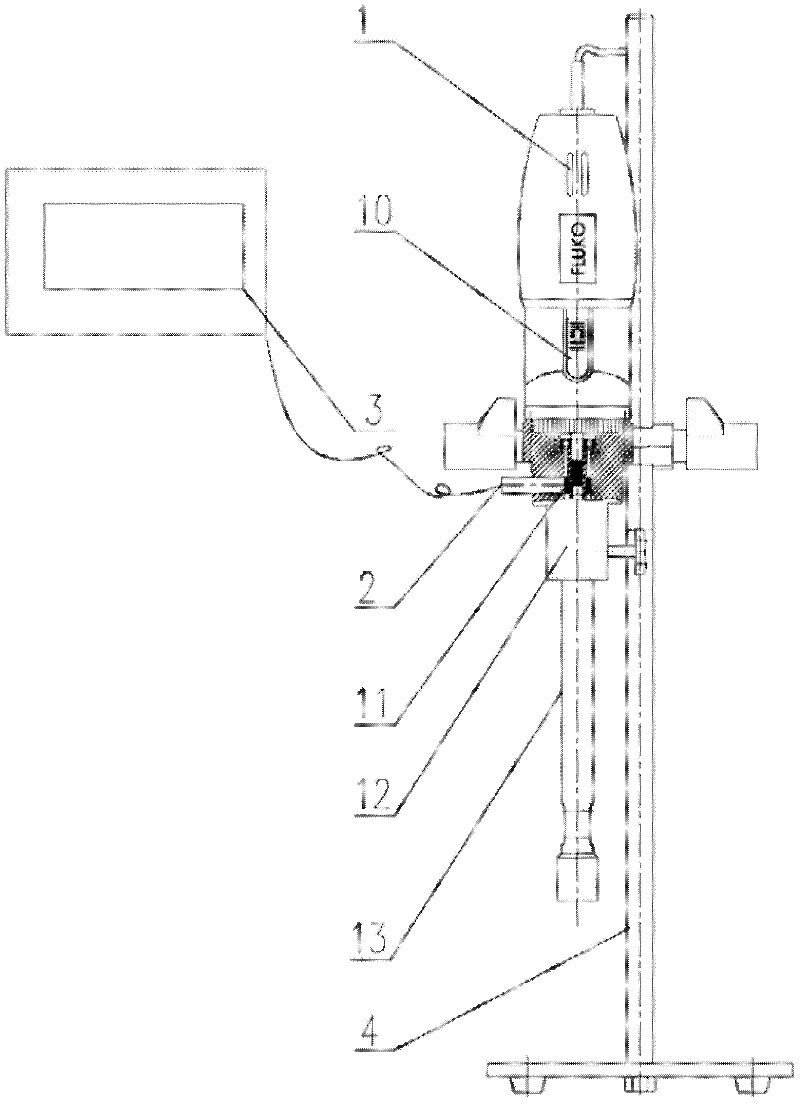

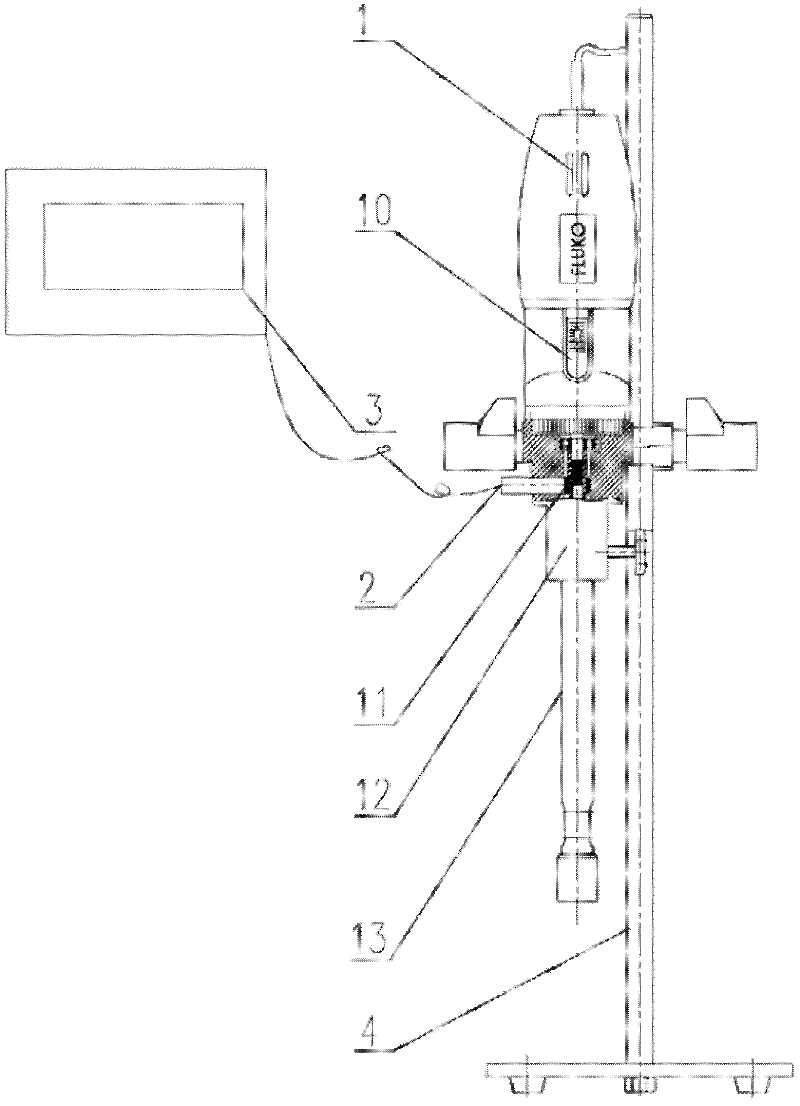

[0007] like figure 1 As shown, the laboratory digital display high-shear dispersing emulsifier includes an electric dispersing emulsifying system 1, a sensor 2, a rotational speed digital display 3 and a working frame 4. The electric dispersing and emulsifying system 1 includes a motor 10 , a gear 11 , a motor combination 12 and a dispersing head 13 . A gear 11 is fixedly installed on the motor shaft of the motor 10 , and the dispersion head 13 is also connected to the motor shaft of the motor 10 and passes through the motor joint 12 . The probe of the sensor 2 is inserted into the motor joint 12 to detect the rotational speed of the gear 11 . The other end of the sensor 2 is connected with the rotational speed digital display instrument 3 . The electric dispersion and emulsification system 1 is fixed on the working frame 5 . The sensor 2 is, for example, a photoelectric or inductive non-contact sensor, which senses the rotation of each tooth of the gear 11 to output a puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com