Method and pressure chamber for measuring crack characteristics of damaged rock

A technology of pressure chamber and rock, which is applied to a method of measuring the characteristics of rock damage cracks in the process of stress and the field of pressure chambers, which can solve problems such as insufficient intuitive understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

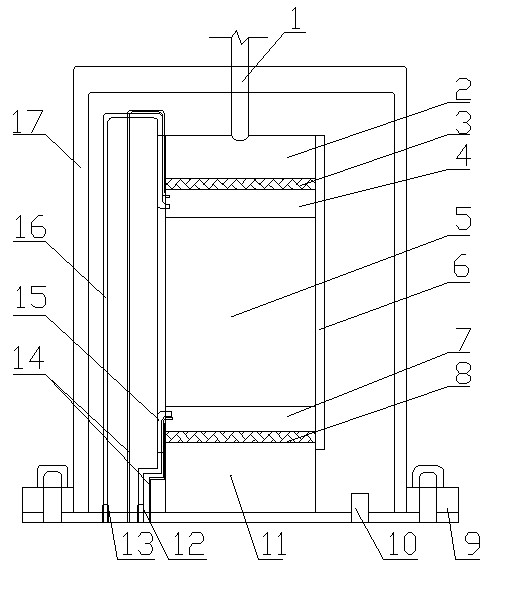

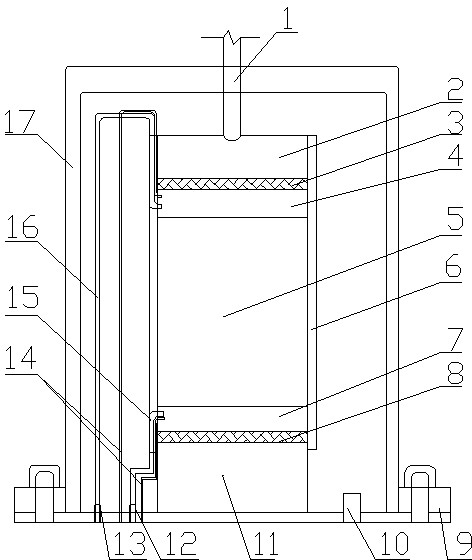

[0019] The pressure chamber of the present invention for measuring the characteristics of damaged rock cracks is as follows: figure 1 As shown, it includes a pressure chamber base 11 and a pressure chamber cover 17. The pressure chamber also includes a pressure chamber, and the sample 5 to be tested is placed in the pressure chamber. Water-proof gasket 3, the top of the upper water-proof gasket 3 is provided with a pressure cap 2, the pressure cap 2 is connected with the pressure rod 1 of the testing machine, and the pressure rod 1 slides and fits with the top of the pressure chamber cover 17; the bottom of the sample is sequentially installed There is a lower water-permeable voltage-conducting plate 7 and a lower water-proof gasket 8, and a rubber film 6 is set around the sample; the upper water-permeable conductive voltage plate and the lower water-permeable voltage-conducting plate are respectively provided with external wires 14; the external wires 14 are connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com