Suspended diaphragm type sound wave soot blower

A technology for sonic sootblowers and diaphragms, which is applied in chemical instruments and methods, combustion product treatment, combustion methods, etc., can solve the problems that diaphragms are susceptible to excessive stress, movement restriction, failure, etc., to avoid premature failure. , The effect of reducing excessive stress and small sound wave loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

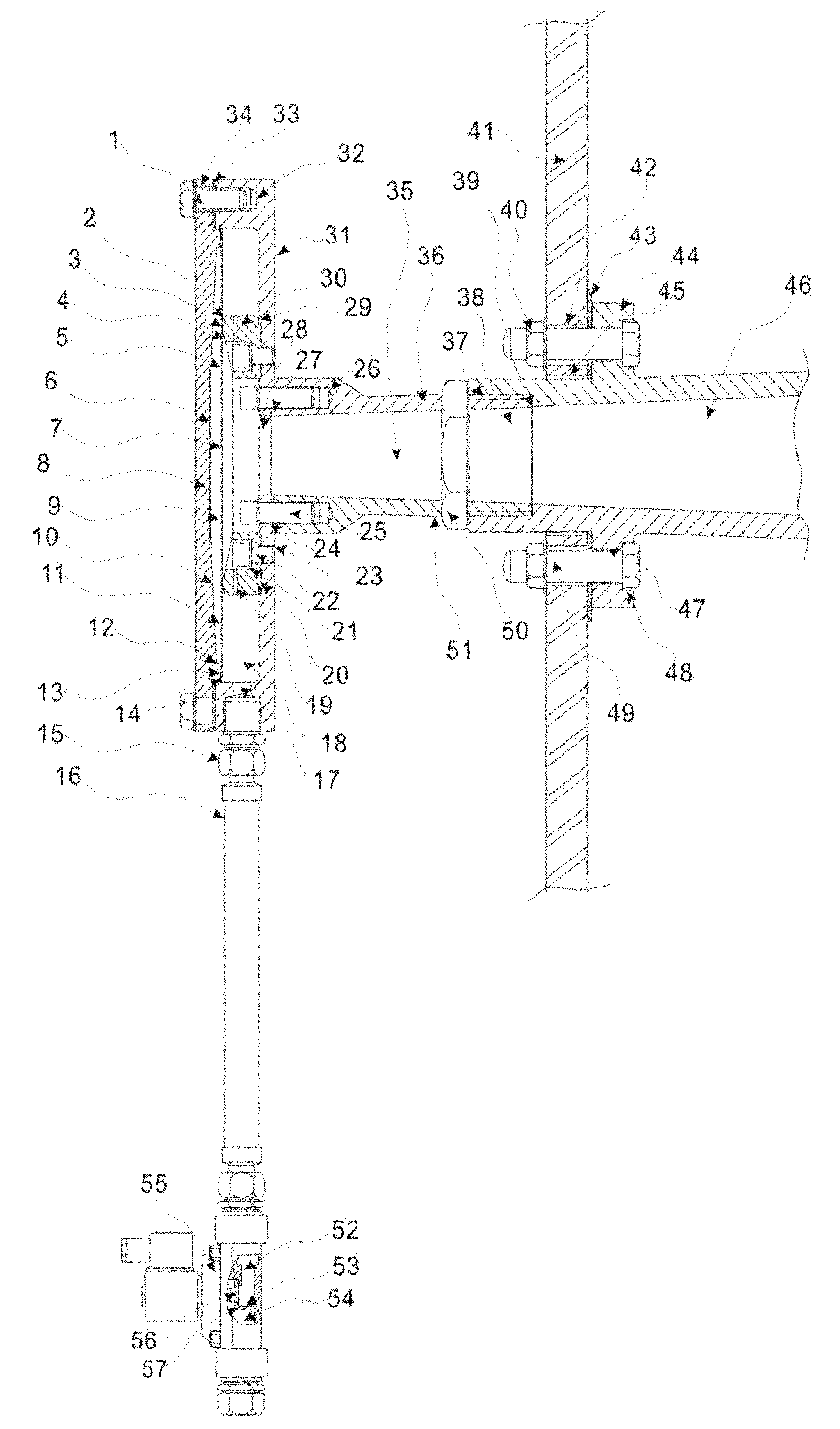

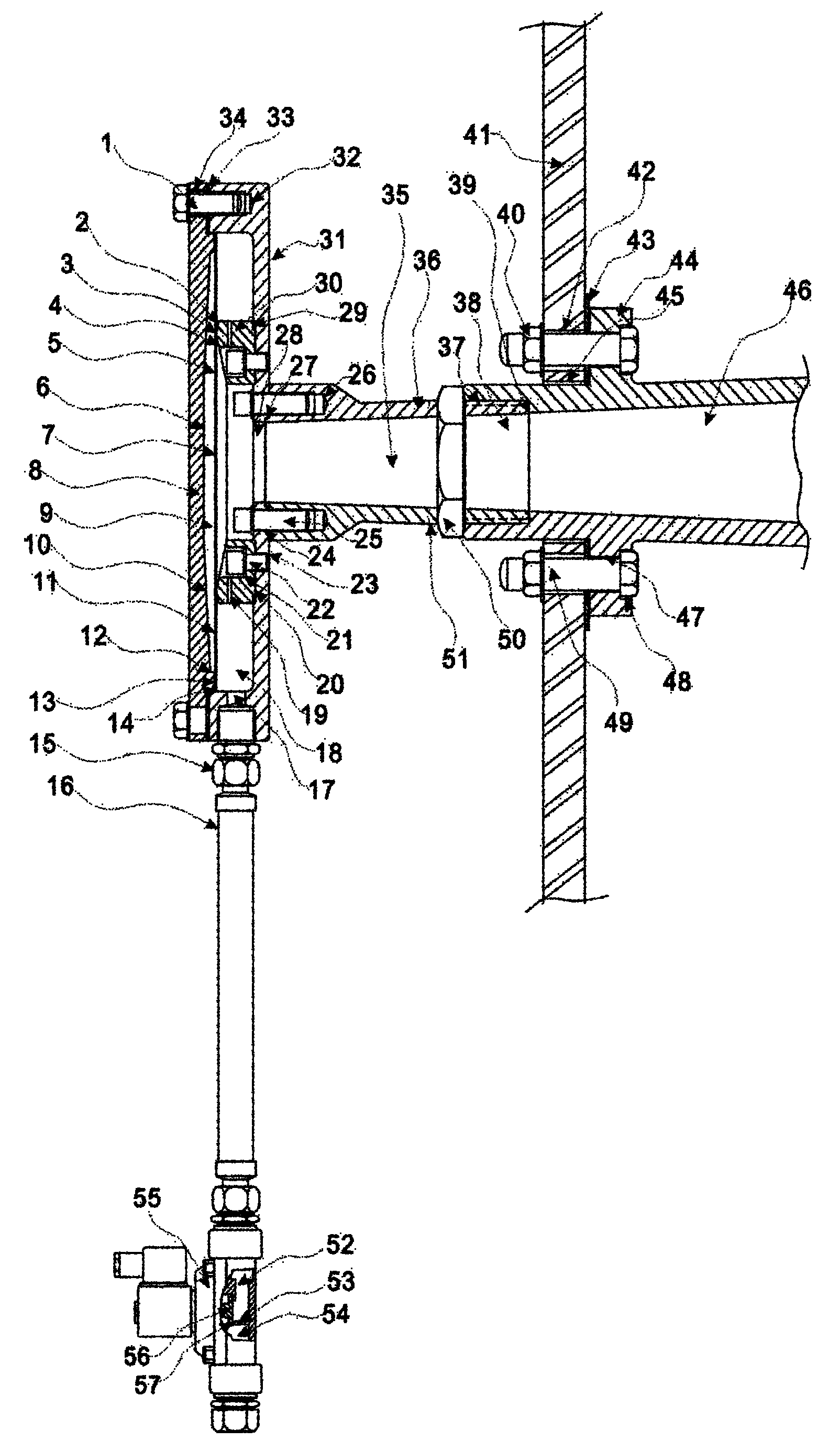

[0020] figure 1Shown is a preferred embodiment provided by the present invention, wherein the sonic sootblower shown is composed of a sonic generator and sonic transmission channels 36 and 46 . The acoustic wave generator includes a U-shaped diaphragm support 31 having a flat bottom and inner and outer walls perpendicular to the bottom and forming rounded corners at intersections. The inner side of the side wall is smooth without steps, so that the diaphragm 7 whose diameter is adapted to the inner diameter of the diaphragm support 31 can move freely without interference during operation. The mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com