Combined technology of catalytic cracking absorbing stabilizing system and C3 intercooling oil absorption

An absorption stabilization system and catalytic cracking technology, which is applied in the technical field of refining and ethylene combination, can solve the problems of high equipment investment, large floor space, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

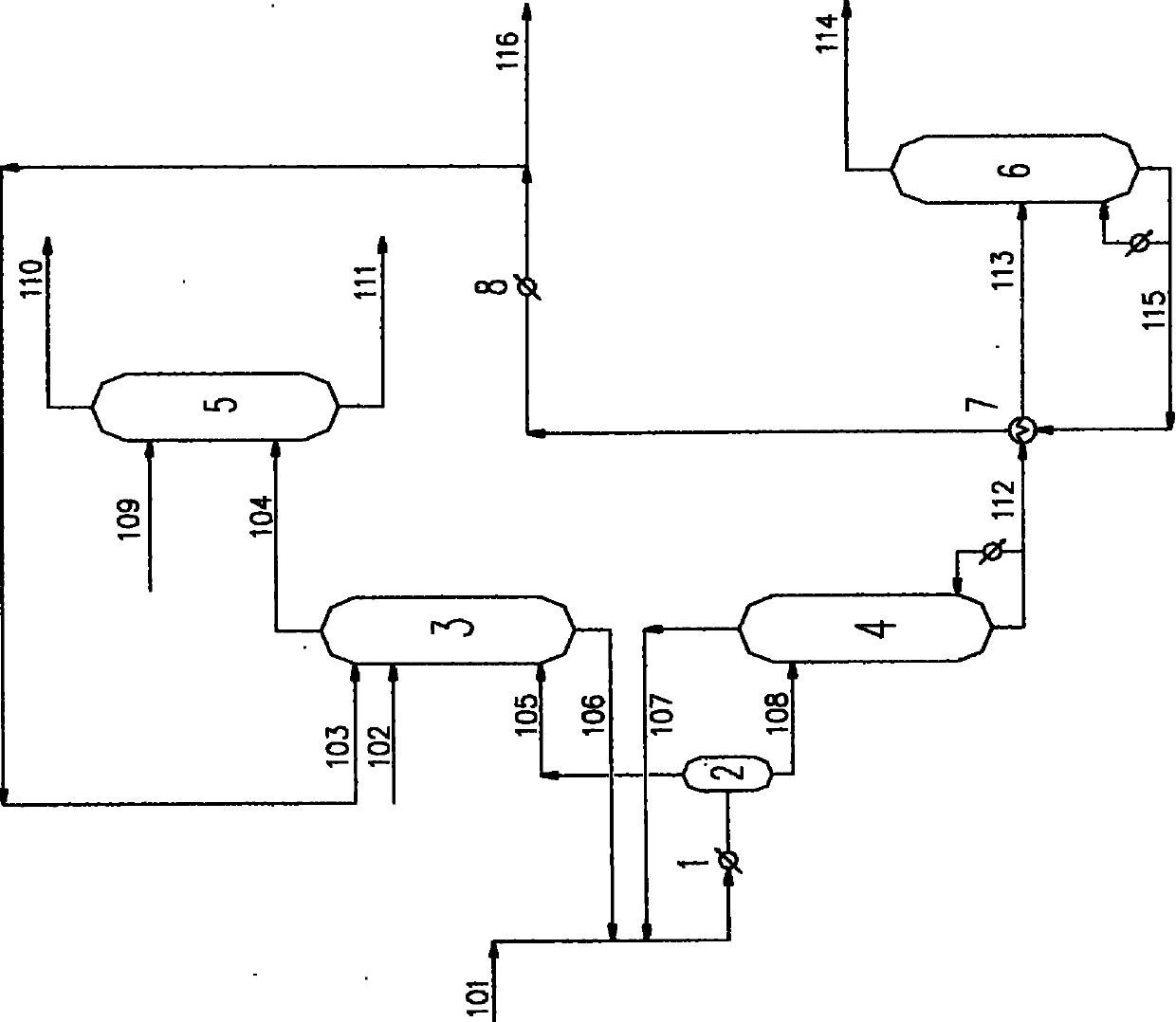

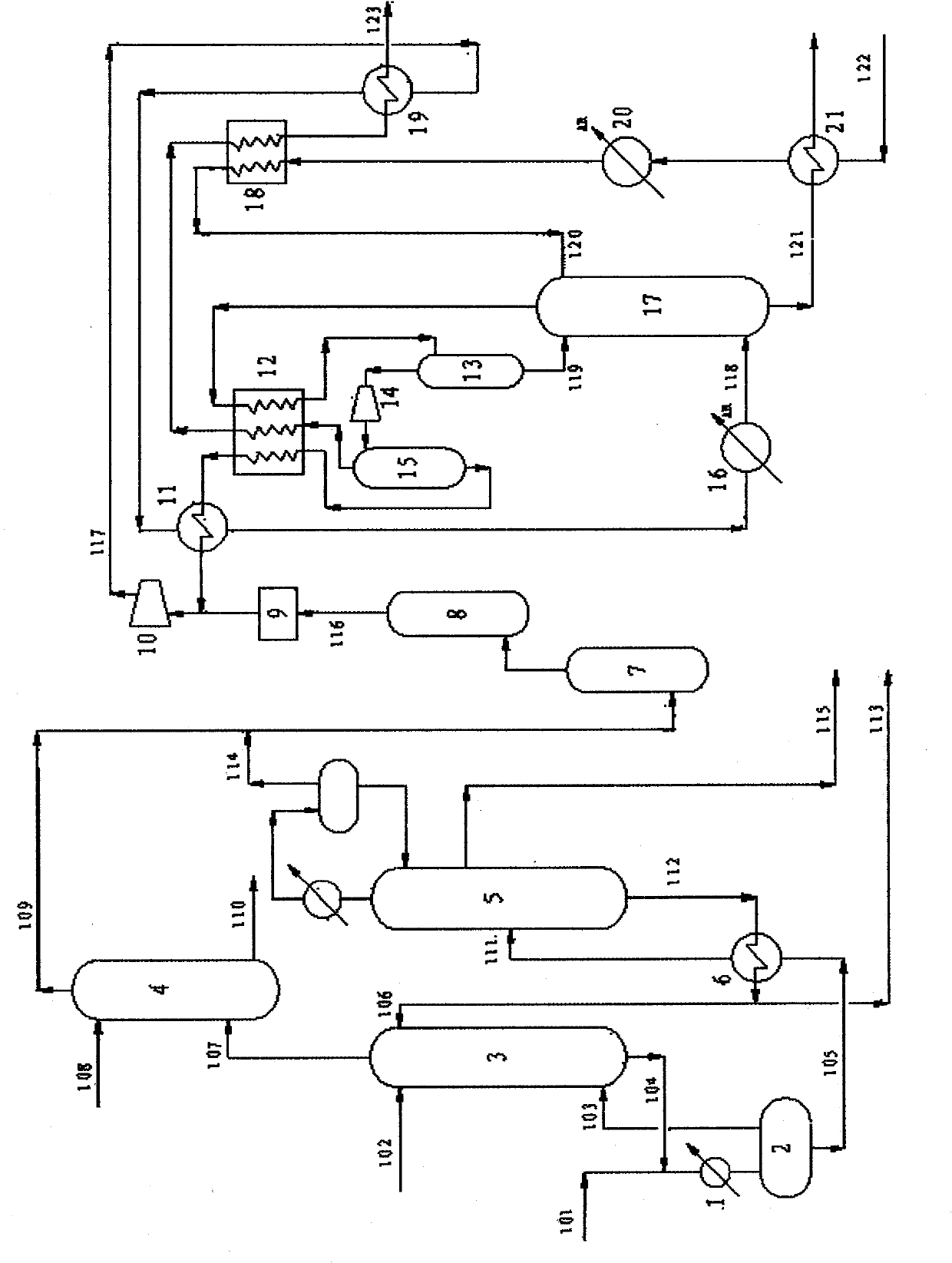

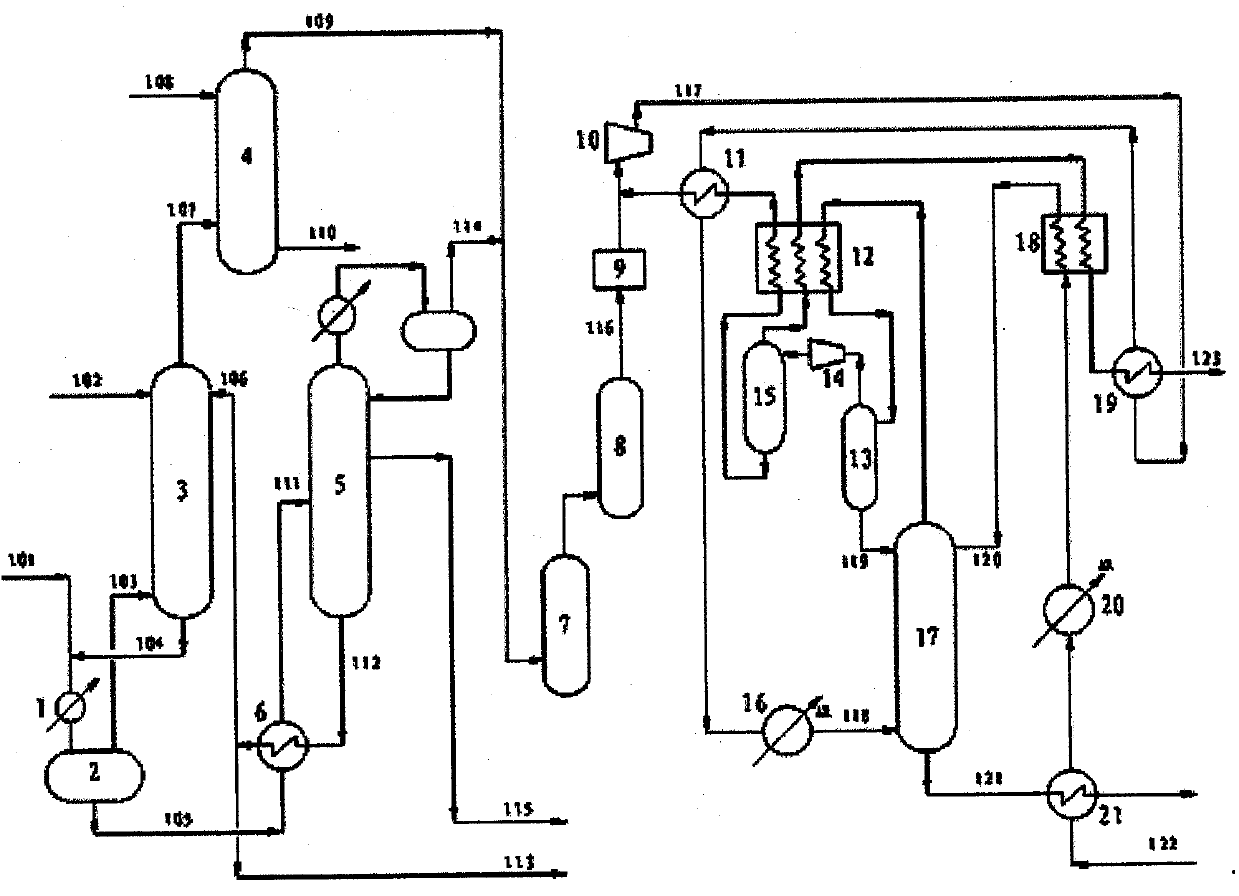

Method used

Image

Examples

Embodiment 1

[0040] See Table 1 for the molar composition of FCC compressed rich gas in a refinery. See Table 2 for the Ernst distillation data of naphtha and light oil used for absorption stabilization.

[0041] The compressed rich gas 101 from the rich gas compressor is mixed with the rich absorption liquid 104 at the bottom of the absorption tower, cooled to 40°C by the cooler 1, and enters the gas-liquid separation tank 2 for equilibrium separation. The operating temperature of the gas-liquid separation tank is 40°C. The operating pressure is 1.45 MPa, and the gas phase 103 from the gas-liquid separation tank enters the bottom of the absorption tower 3 . The theoretical plate number of the absorption tower is preferably 12, the operating pressure is 1.37MPa, the temperature at the top of the tower is 43.2°C, and the temperature at the bottom of the tower is 45.2°C. In the absorption tower, naphtha 102 and supplementary absorbent 106 are used as absorbents to enter the top of the absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com