Aqueous UV (ultraviolet) printing ink dispersed by utilizing vermiculate micelle system and preparation method thereof

A worm-like micelle and system technology, applied in the field of water-based UV ink and its preparation, can solve the problems of time-consuming, manpower, material and financial resources, water-based ink adaptability is not as good as oil-based ink, poor adhesion, etc., to achieve smooth surface, High gloss, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of water-based UV ink, according to weight percentage, comprises following components:

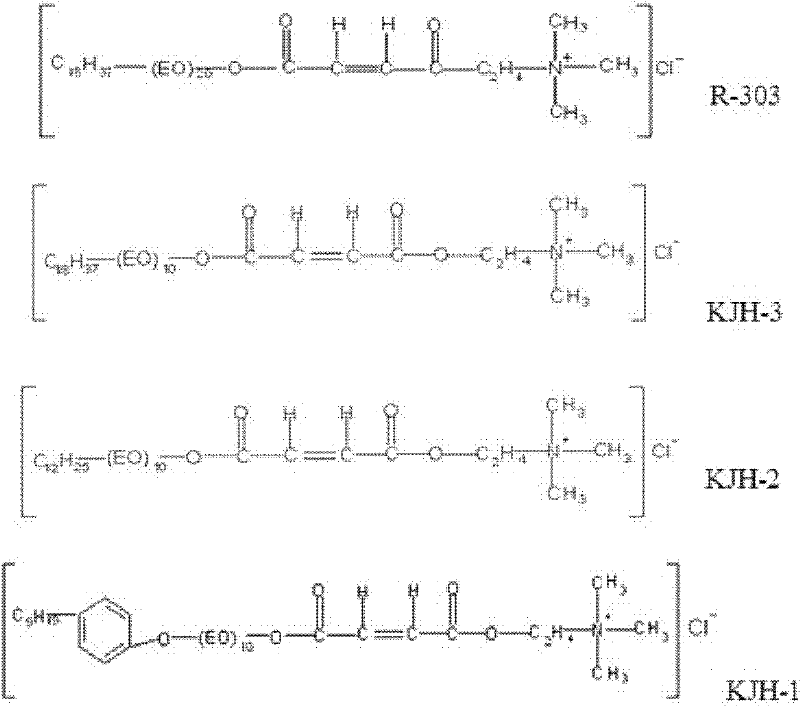

[0037] 28% R-303 and sodium polystyrene sulfonate composite surfactant;

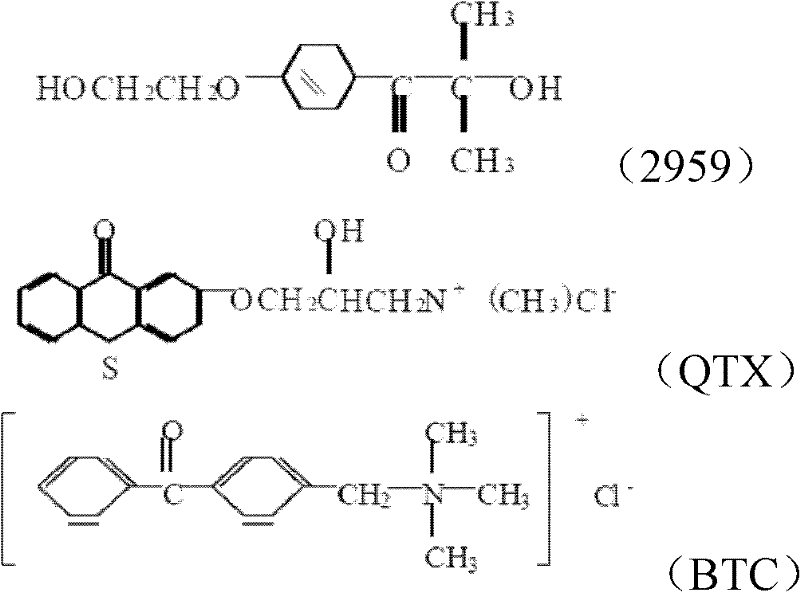

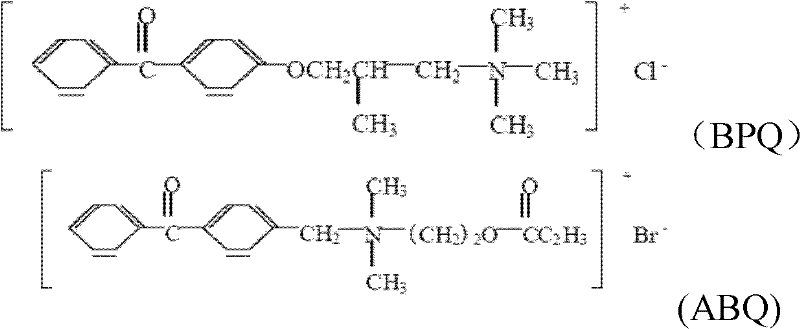

[0038] 5% 2959 and BTC composite UV photoinitiator;

[0039] 15% dimethylquinacridone magenta pigment;

[0040] 5% light reflective functional filler;

[0041] 1.5% Silok 4650 water-based defoamer;

[0042] 0.5% Silok 50 slip agent;

[0043] 40% water;

[0044] 5% methyl acrylate and acrylic monomers.

[0045] Among them, the molar ratio of R-303 and sodium polystyrene sulfonate is 1:2; the number average molecular weight of sodium polystyrene sulfonate is 20,000; the molar ratio of 2959 and BTC is 2:1; the molar ratio of methyl acrylate and acrylic acid The ratio is 1:1.

[0046] The preparation method is as follows: (1) dimethyl quinacridone pigment, light reflective filler, defoamer, slip agent, photoinitiator and monomer that have been ground to a particle size of 5 μm or less are ultrasonica...

Embodiment 2

[0048] A kind of water-based UV ink, according to weight percentage, comprises following components:

[0049] 20% KJH-2 and sodium polystyrene sulfonate composite surfactant;

[0050] 10% 2959 and BTC composite UV photoinitiator;

[0051] 15% nigrosine black pigment;

[0052] 10% light reflective functional filler;

[0053] 3% Silok 4650 water-based defoamer;

[0054] 2% Silok 50 slip agent;

[0055] 30% water;

[0056] 10% methyl acrylate and acrylic monomers.

[0057] Among them, the molar ratio of KJH-2 and sodium polystyrene sulfonate is 3:1; the number average molecular weight of sodium polystyrene sulfonate is 30,000; the molar ratio of 2959 and BTC is 1:1; the molar ratio of methyl acrylate and acrylic acid The ratio is 1:1.

[0058] The preparation method is as follows: (1) The nigrosine pigment, light reflective filler, defoamer, slip agent, photoinitiator and monomer that have been ground to a particle size of 5 μm or less are dispersed in the aqueous solution o...

Embodiment 3

[0060] A kind of water-based UV ink, according to weight percentage, comprises following components:

[0061] 20% KJH-3 and polyacrylic acid composite surfactant;

[0062] 8% 2959 and QTX composite UV photoinitiator;

[0063] 30% anthraquinone yellow pigment;

[0064] 5% light reflective functional filler;

[0065] 1.5% Silok 4830 water-based defoamer;

[0066] 0.5% Silok 50 slip agent;

[0067] 30% water;

[0069] Among them, the molar ratio of KJH-3 and polyacrylic acid is 0.9:1.05; the number average molecular weight of polyacrylic acid is 35000; the molar ratio of 2959 and QTX is 2:1.

[0070] The preparation method is as follows: (1) disperse anthraquinone pigments, light reflective fillers, defoamers, slip agents, photoinitiators and monomers that have been ground to a particle size of 5 μm or less in an aqueous solution of KJH-3 for 1 hour, Remove ununiformly dispersed solid particles by filtration, the ultrasonic frequency is 40kHz, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com