Polyphosphazene-ether amide material and preparation method thereof

A technology of ether amide and polyphosphazene, which is applied in the field of polyphosphazene-ether amide material and its preparation, can solve the problems of single material solubility, harsh processing and preparation process, etc., and achieves good thermal stability, good solubility, good The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

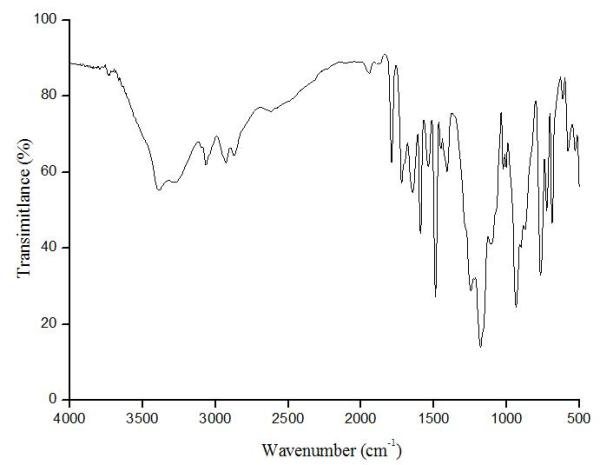

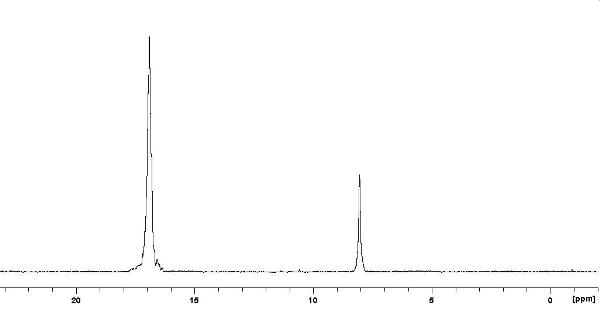

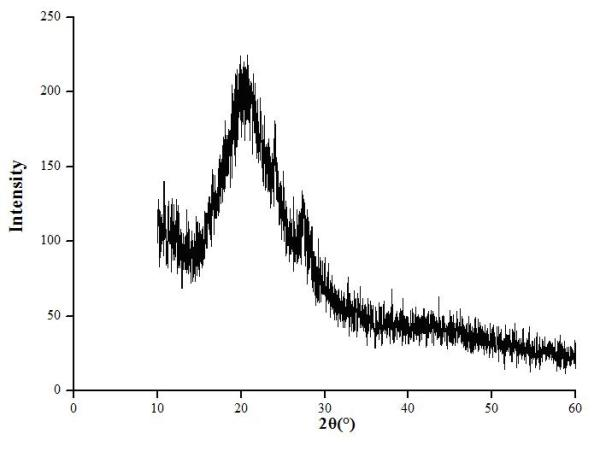

Image

Examples

Embodiment 1

[0025] The synthesis of polyphosphazene-ether amide material is realized through the following steps:

[0026] (1) In a 500mL three-neck flask equipped with magnetic rotor stirring, condenser and thermometer, dissolve hexachlorocyclotriphosphazene (17.4g 0.05mol) prepared by multiple sublimation in 50mL tetrahydrofuran (THF) solvent, add dropwise Prepared (2.32g 0.2mol) sodium phenate (under nitrogen protection, (4.6g 0.2mol) sodium metal and (18.822g 0.2mol) phenol reacted in 50mL THF solution at 25°C for 2 hours) THF solution, nitrogen Protected and reacted at 40°C for 12 hours. THF was removed by rotary distillation, washed several times with deionized water, and vacuum-dried at 50°C for 24 hours to obtain a milky white colloid.

[0027] (2) In a 500mL three-neck flask equipped with a magnetic rotor stirring, a condenser, and an HCl absorption device, dissolve the (10.37g 0.018mol) milky white colloid obtained in step (1) in 100mL THF solvent, and add (8g 0.04mol) of 4,4'...

Embodiment 2

[0030] The synthesis of polyphosphazene-ether amide material is realized through the following steps:

[0031] (1) In a 500mL three-neck flask equipped with magnetic rotor stirring, condenser and thermometer, dissolve hexachlorocyclotriphosphazene (13.9g 0.04mol) prepared by multiple sublimation in 50mL tetrahydrofuran (THF) solvent, add dropwise Prepared (1.856g 0.16mol) sodium phenate (under nitrogen protection, (3.68g 0.16mol) metal sodium and (15.06g 0.16mol) phenol reacted in 50mL THF solution at 25°C for 2 hours) THF solution, nitrogen Protected and reacted at 40°C for 12 hours. THF was removed by rotary distillation, washed several times with deionized water, and vacuum-dried at 50°C for 24 hours to obtain a milky white colloid.

[0032] (2) In a 500mL three-neck flask equipped with a magnetic rotor stirring, a condenser, and an HCl absorption device, dissolve the (11.52g 0.02mol) milky white colloid obtained in step (1) in 50mL of THF solvent, and add (8g 0.04mol) of...

Embodiment 3

[0035] The synthesis of polyphosphazene-ether amide material is realized through the following steps:

[0036] (1) In a 500mL three-neck flask equipped with magnetic rotor stirring, condenser and thermometer, hexachlorocyclotriphosphazene prepared by multiple sublimation (34.8g 0.1mol) was dissolved in 100mL tetrahydrofuran (THF) solvent, and added dropwise Prepared (9.28g 0.4mol) sodium phenate (prepared by reacting (9.2g 0.4mol) metal sodium and (37.64g 0.4mol) phenol in 100mL THF solution at 25°C for 2 hours under nitrogen protection) THF solution, nitrogen Protected and reacted at 40°C for 24 hours. THF was removed by rotary distillation, washed several times with deionized water, and vacuum-dried at 50°C for 24 hours to obtain a milky white colloid.

[0037] (2) In a 500mL three-neck flask equipped with a magnetic rotor stirring, a condenser, and an HCl absorption device, dissolve the (28.81g 0.05mol) milky white colloid obtained in step (1) in 100mL THF solvent, and add (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com