Method for brickmaking by comprehensive utilization of desiccated sludge

A technology for making bricks and sludge from sludge, which is applied in the direction of dehydration/drying/concentrated sludge treatment, application, household appliances, etc. It can solve the problems of impact strength, poor effect, and easy to crisp, so as to save energy and increase its own heat , Excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

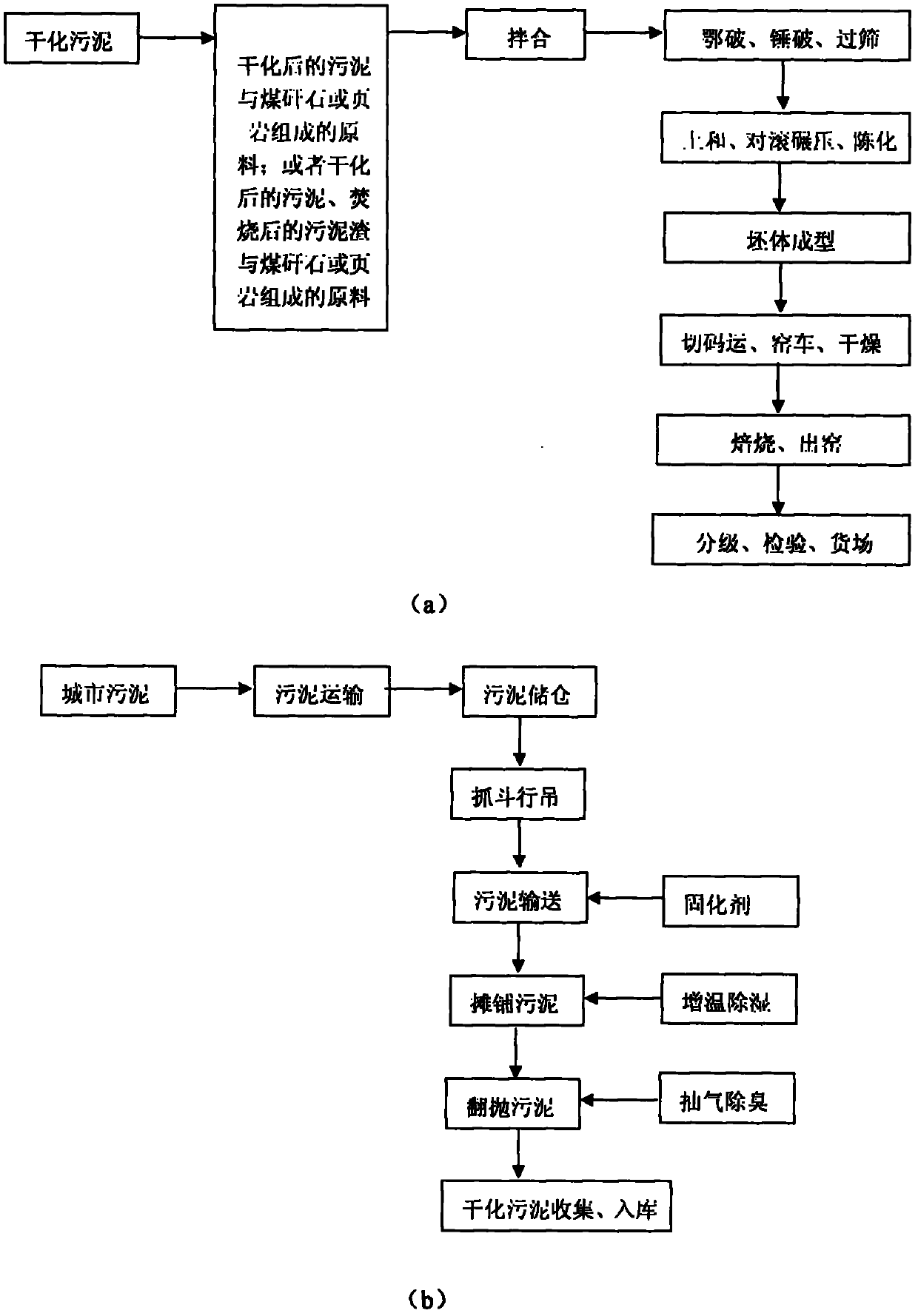

[0060] Drying sludge: Dry the municipal sludge with a moisture content of 80-85% through a drying system to obtain dried sludge with a moisture content of 10%-25% and a loss on ignition of 26%-29% .

[0061] Ingredients: According to the ratio of dried urban sludge: coal gangue = 30:70, the raw materials are mixed, and the particle size of the crushed material is required to be ≤5cm, the particle size of the hammered material is required to be ≤1cm, and the particle size of the sieve ≥6 mesh). Then enter the brick making process according to the ordinary brick making process.

[0062] Forming: control extrusion pressure ≥ 3.5MPa, vacuum degree ≥ 98%.

[0063] Sintering: Sintering for 3 hours under the condition of controlling the maximum temperature of 1080 degrees to obtain microporous porous bricks, such as Figure 10 shown.

[0064] After leaving the kiln, it is sorted and stored in the cargo yard. The outer size is qualified, the brick strength is ≥ MU10 and the block ...

Embodiment 2

[0066] The specific process steps are the same as in Example 1, except that the ratio of raw materials is as follows: dried municipal sludge: shale: internal fuel = 35:60:5.

[0067] The sintering is controlled under the condition that the maximum temperature is 1050 degrees, and sintering is performed for 2.5 hours.

Embodiment 3

[0069] Concrete process step is identical with embodiment 1, and difference is that raw material proportioning is as follows: sludge after drying: municipal sludge slag after burning: coal gangue=20: 30: 50

[0070] Under the condition of sintering control with a maximum temperature of 1100 degrees, sintering for 1.5 hours to obtain a microporous porous block, such as Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com