Natural color sand production line

A natural colored sand and production line technology, which is applied in grain processing and other directions, can solve the problems of dusty production process, uneven and delicate wall surface, and large granularity of colored sand, so as to improve the quality of production environment, pure color, and low operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

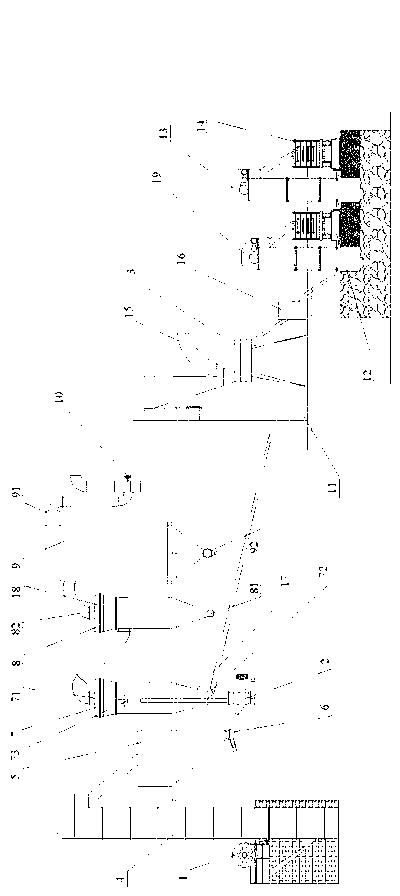

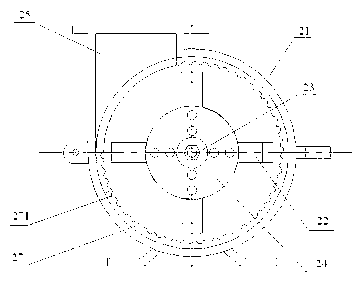

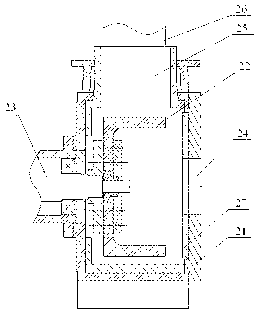

[0031] Natural colored sand production line such as figure 1 As shown, it mainly includes a jaw crusher 1, a pulverizer 2, a linear screen 3, a rotary screen, an analyzer, and a star unloader arranged in sequence. The production line of the present invention is provided with an air supply system and a stone material production system.

[0032] The specific structure of the stone production system in this embodiment is as follows.

[0033] The inlet of the jaw crusher is directly connected to the conveyor belt for transporting stones, the outlet of the jaw crusher is connected to the bottom of the elevator I, and the outlet of the elevator I is connected to the bin 5, and the outlet of the bin is connected to the electromagnetic feeder 6 It is connected to the feed port 24 of the pulverizer, and the discharge port 25 of the pulverize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com