Desulfurizer and preparation method thereof

A desulfurizer and adhesive technology, applied in chemical instruments and methods, other chemical processes, organic chemistry, etc., can solve the problems of low sulfur capacity and difficult preparation of desulfurizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

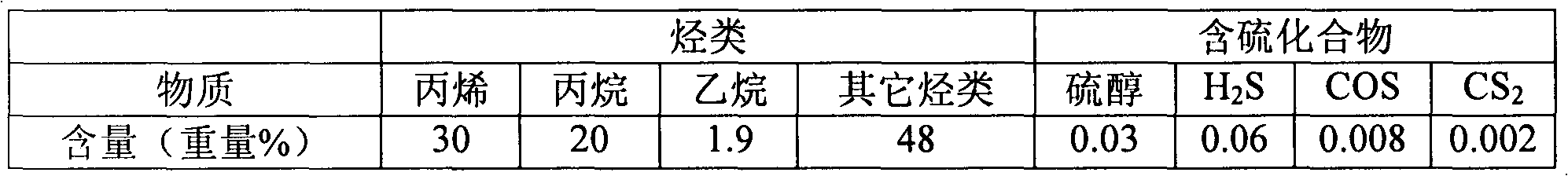

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The present invention also provides a method for preparing a desulfurizer, the method comprising molding and activating a raw material mixture containing zinc oxide, sodium carbonate and a binder.

[0013] In a preferred embodiment, in order to further increase the sulfur capacity of the prepared desulfurizer, zinc carbonate is added to the raw material mixture. The zinc carbonate can expand pores, so that the finally prepared desulfurizer has increased pore volume and pore diameter, thereby increasing the sulfur capacity of the desulfurizer.

[0014] In the process of preparing the desulfurizer, the addition amount of the zinc carbonate is not particularly limited, however, in order to significantly improve the sulfur capacity of the final prepared desulfurizer, relative to 100 parts by weight of the raw material mixture, the zinc carbonate The amount of zinc added is preferably 1-15 parts by weight, more preferably 3-12 parts by weight.

[0015] In the process of pre...

Embodiment 1

[0019] This example is used to illustrate the desulfurizing agent provided by the present invention and its preparation method.

[0020] Mix 67 parts by weight of zinc oxide, 11 parts by weight of sodium carbonate, 11 parts by weight of zinc carbonate, 11 parts by weight of sodium metaaluminate and an appropriate amount of water to make a mixed slurry, and then extrude it with a twin-screw extruder It was molded and dried at 120°C, then activated at 380°C for 2 hours under the protection of nitrogen, and then cooled to room temperature to obtain desulfurizer A1.

Embodiment 2

[0022] This example is used to illustrate the desulfurizing agent provided by the present invention and its preparation method.

[0023] The zinc oxide of 65 parts by weight, the sodium carbonate of 14 parts by weight, the zinc carbonate of 7 parts by weight, the kaolin of 14 parts by weight and an appropriate amount of water are mixed to make a mixed slurry, and then extruded with a twin-screw extruder, and dried at 120°C, then activated at 450°C for 1.5 hours under the protection of nitrogen, and then cooled to room temperature to obtain desulfurizer A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com