Filtering method and filtering device with alternating electric field on filter element

A filter device and filter method technology, applied in the direction of filter separation, separation method, chemical instrument and method, etc., can solve the problems of filter and solution properties, unfavorable aggregation of small particles, charged particles, etc., to achieve increased filter effect and stability, The effect of increasing the chance of coagulation and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

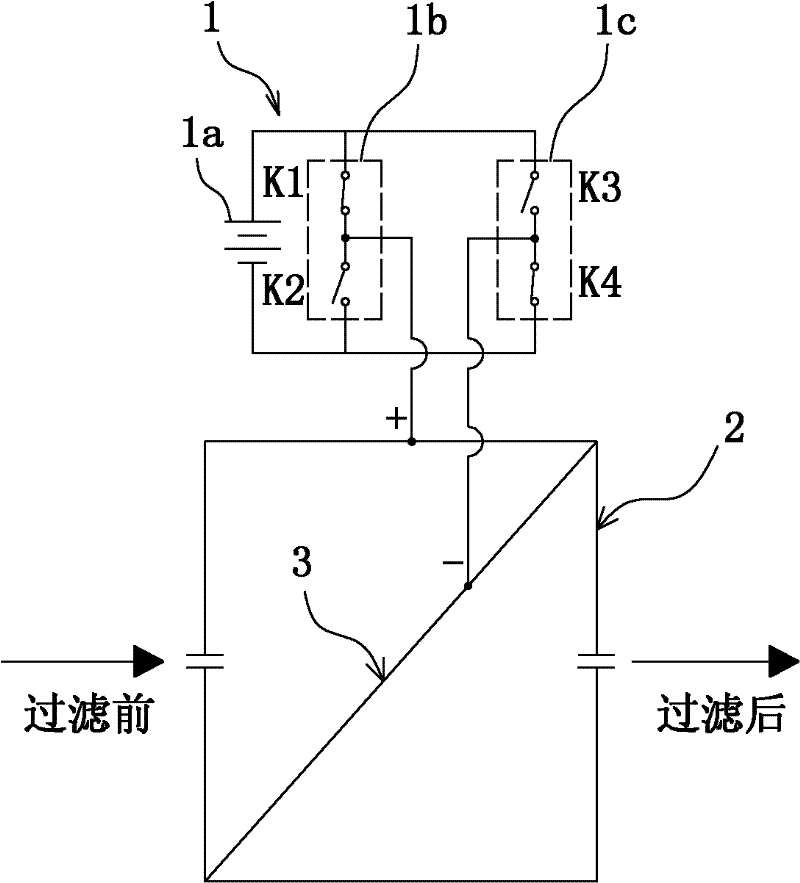

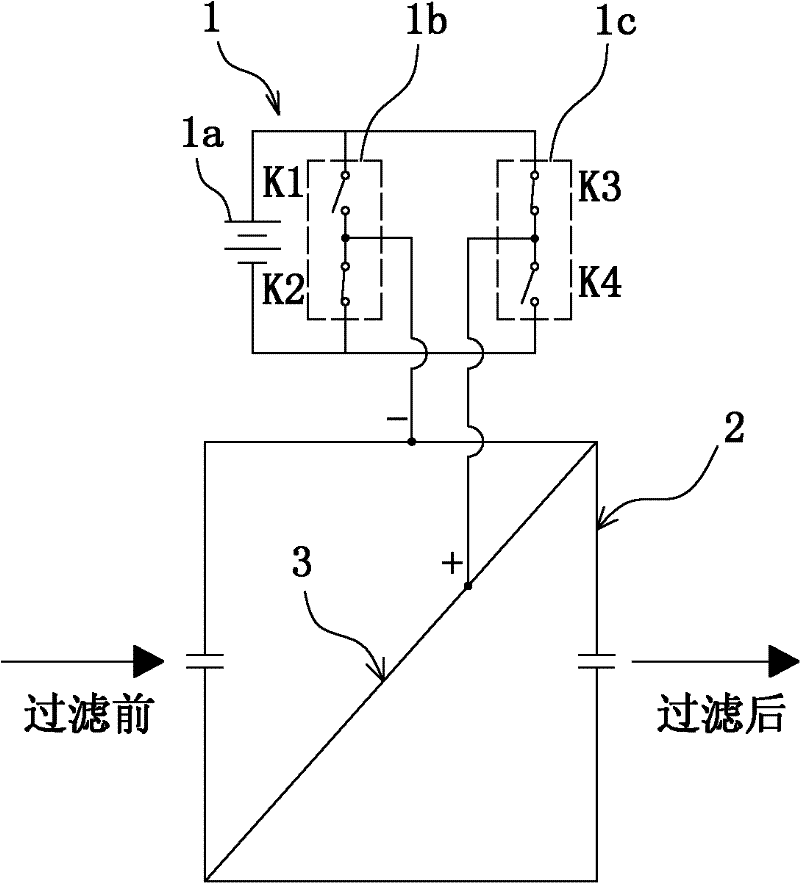

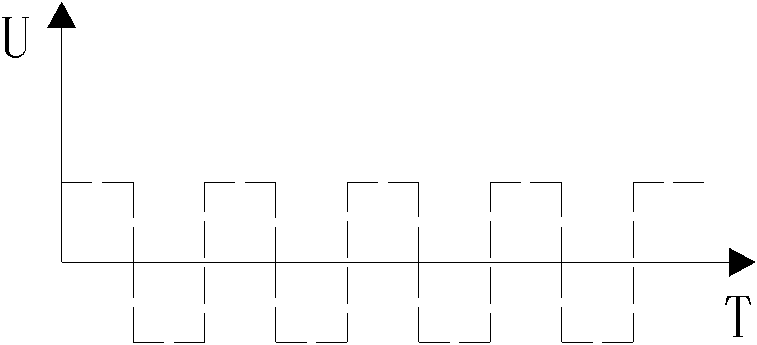

[0025] The filter device used in high-temperature gas filtration uses FeAl intermetallic compound porous material as the filter element, the gas temperature is 200°C during filtration, and the filter pressure difference is 1kPa. A 50-volt voltage is applied between the filter element 3 and the shell 2 of the filter device. Alternating voltage, the alternating frequency is 15HZ, and the filtering result is significantly higher than the filtering stability when a 50V DC voltage is applied between the filter element 3 and the shell 2 . Reflected in Figure 4 Among them, in order to maintain the filtration flux constant, when the above-mentioned alternating voltage is applied between the filter element and the shell, the filtration pressure difference remains basically unchanged over time, or even slightly decreases (indicating that a large number of small particles of charged particles are agglomerated); while when After a DC voltage is applied between the filter element and the ...

Embodiment 2

[0027] The filter device used in high-temperature gas filtration uses FeAl intermetallic compound porous material as the filter element, the gas temperature is 200°C during filtration, and the filter pressure difference is 3kPa. A 50-volt voltage is applied between the filter element 3 and the shell 2 of the filter device. Alternating voltage, the alternating frequency is 45HZ, and the filtering result is obviously improved in filtering stability compared with the case of applying 50V DC voltage between the filter element 3 and the shell 2.

Embodiment 3

[0029] The filter device used in liquid filtration uses TiAl intermetallic compound porous material as the filter element, the membrane surface flow velocity is 4m / s during cross-flow filtration, and the filtration pressure difference is 30kPa. The alternating voltage is 10 volts, the alternating frequency is 45HZ, and the filtering result is obviously improved compared with the case of applying a 10 volt direct current voltage between the filter element 3 and the shell 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com