Anti-reflection plastic film and preparation method thereof

A plastic film and anti-reflection technology, applied in chemical instruments and methods, coatings, instruments, etc., can solve the problems of weakening the mechanical strength of the coating film, poor anti-reflection effect, reducing weather resistance or water resistance, etc., to achieve excellent anti-reflection Effect of reflection, excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

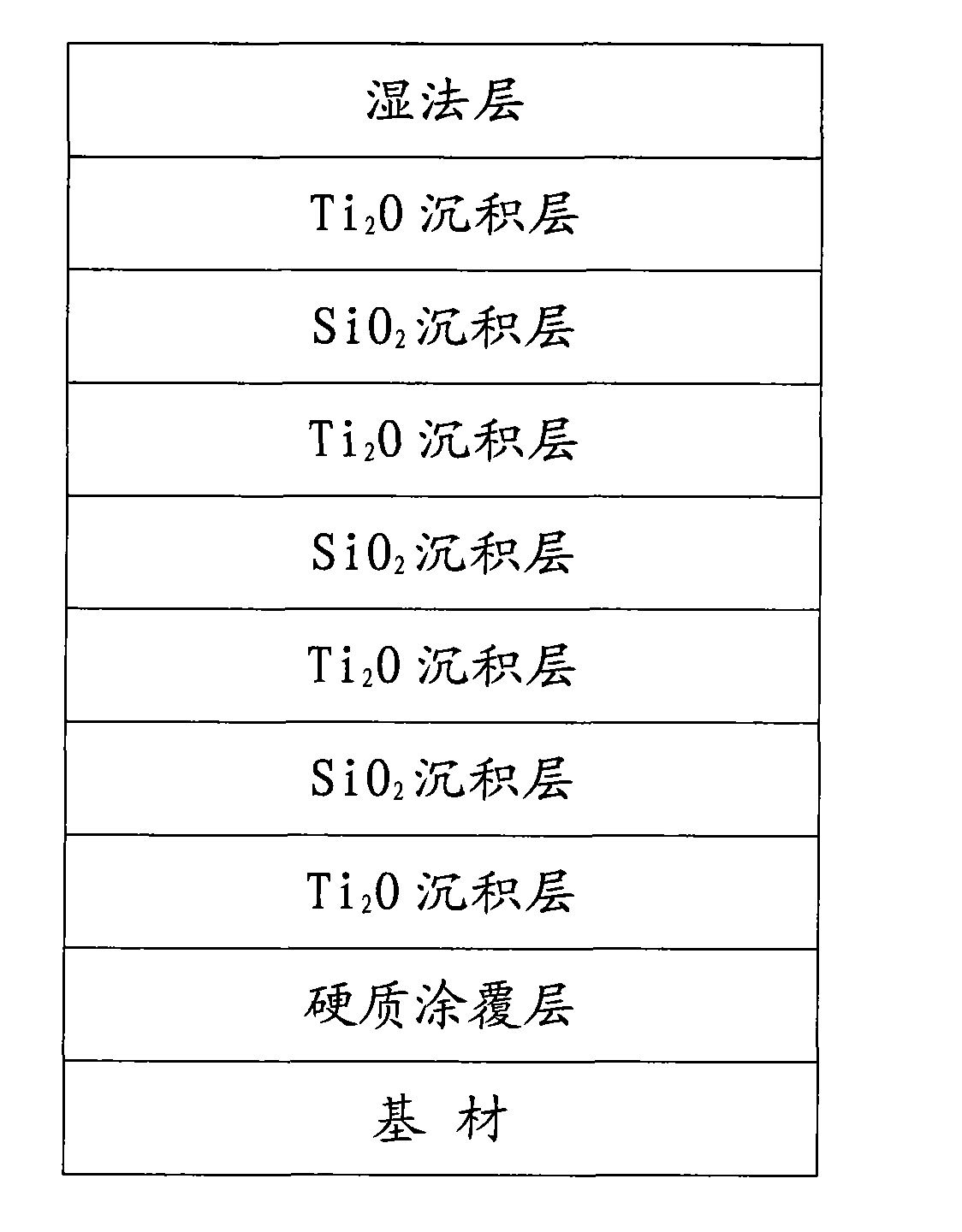

[0023] The technical scheme of the present invention is described in detail below, as figure 1 The schematic cross-sectional view of the anti-reflection plastic film of an embodiment of the present invention shown, in the figure, the bottom layer is the base material, and the base material is coated with a hard coating layer, and the hard coating layer coating in this embodiment On the upper surface of the substrate, of course, the hard coating layer can also be coated on the lower surface of the substrate or both the upper and lower surfaces, and the hard coating layer is alternately coated with Ti 2 O deposition layer and SiO 2 The deposition layer is used as a high refractive index deposition layer and a low refractive index deposition layer, and their refractive indices are 1.6-2.35 and 1.35-1.5 respectively. In this embodiment, Ti 2 O deposition layer and SiO 2 Ti 2 The O deposition layer has 7 layers in total to form a deposition layer. In the actual film, the number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scratch resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com