Hair curler

A hair curler and heating element technology, applied in the field of beauty and hairdressing, can solve the problems of damaged hair, poor coordination, and low heat transfer efficiency, and achieve the effects of simplified production process, small temperature difference range, and accurate and reliable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

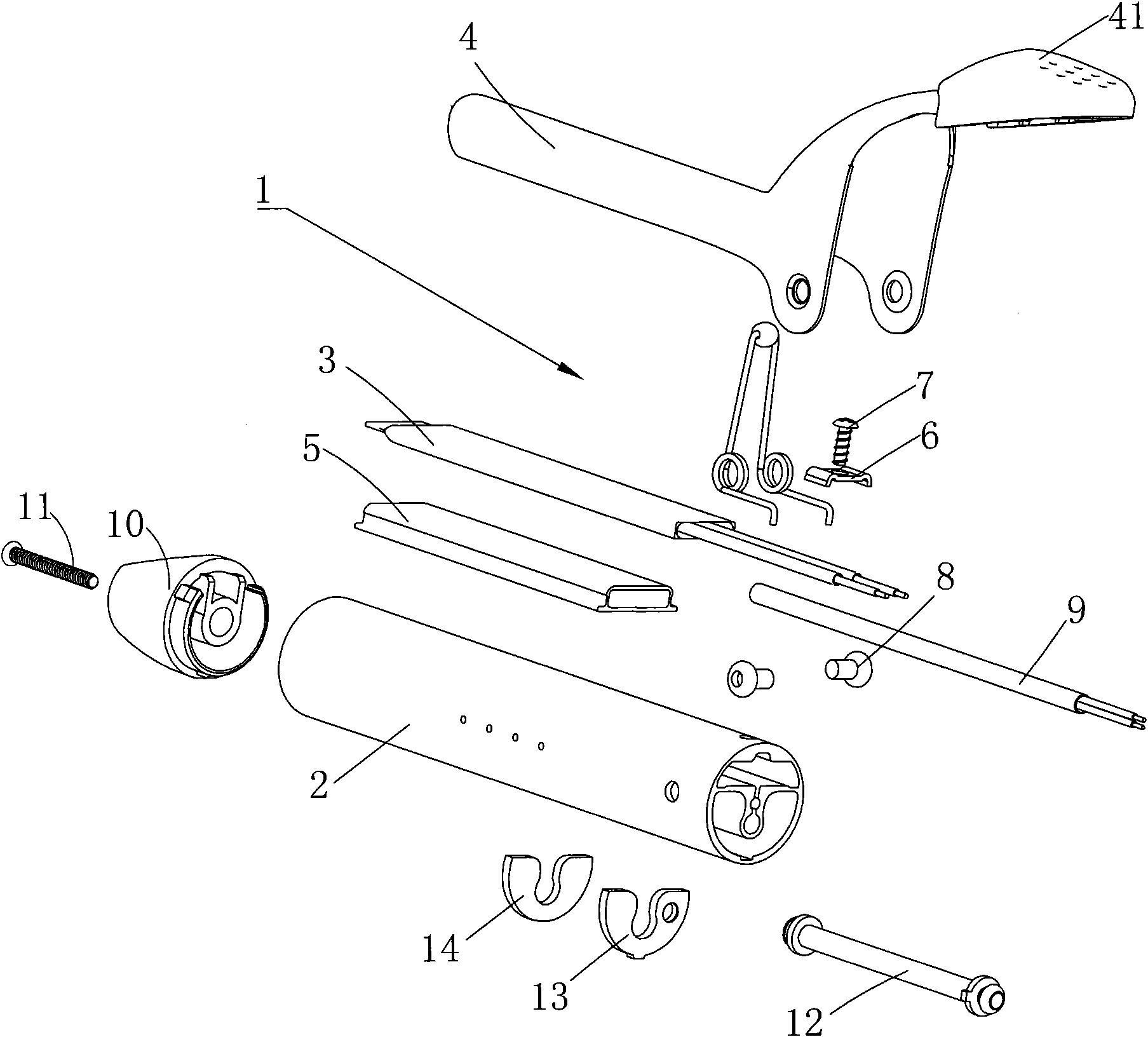

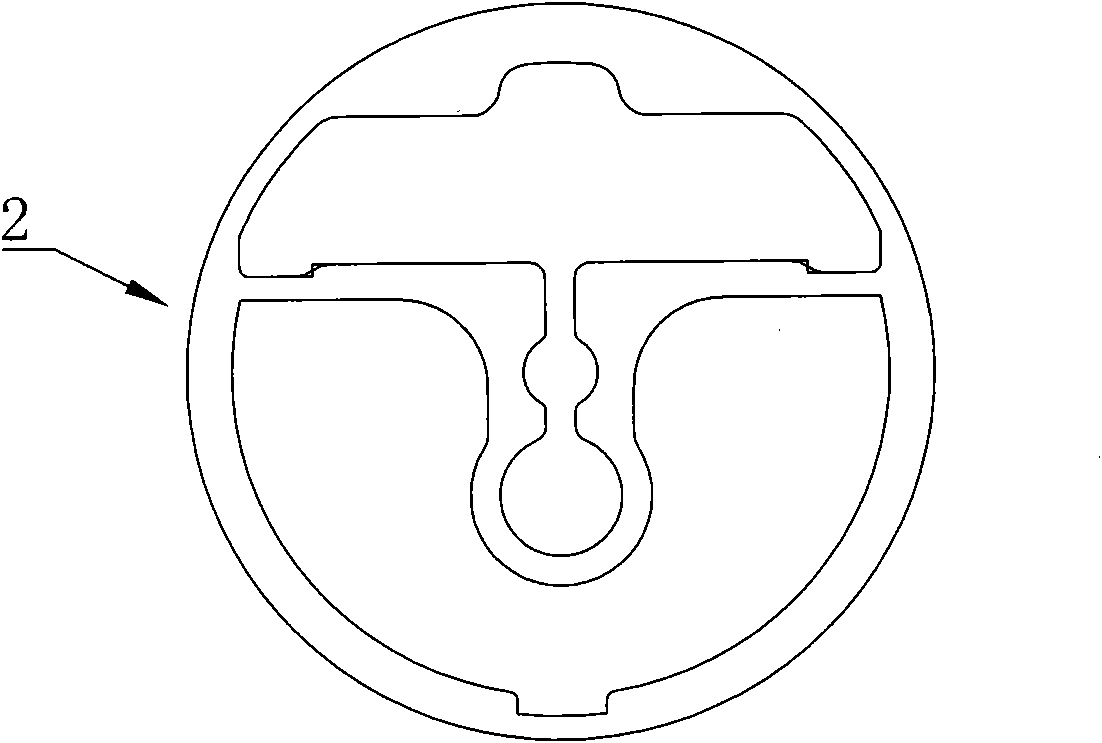

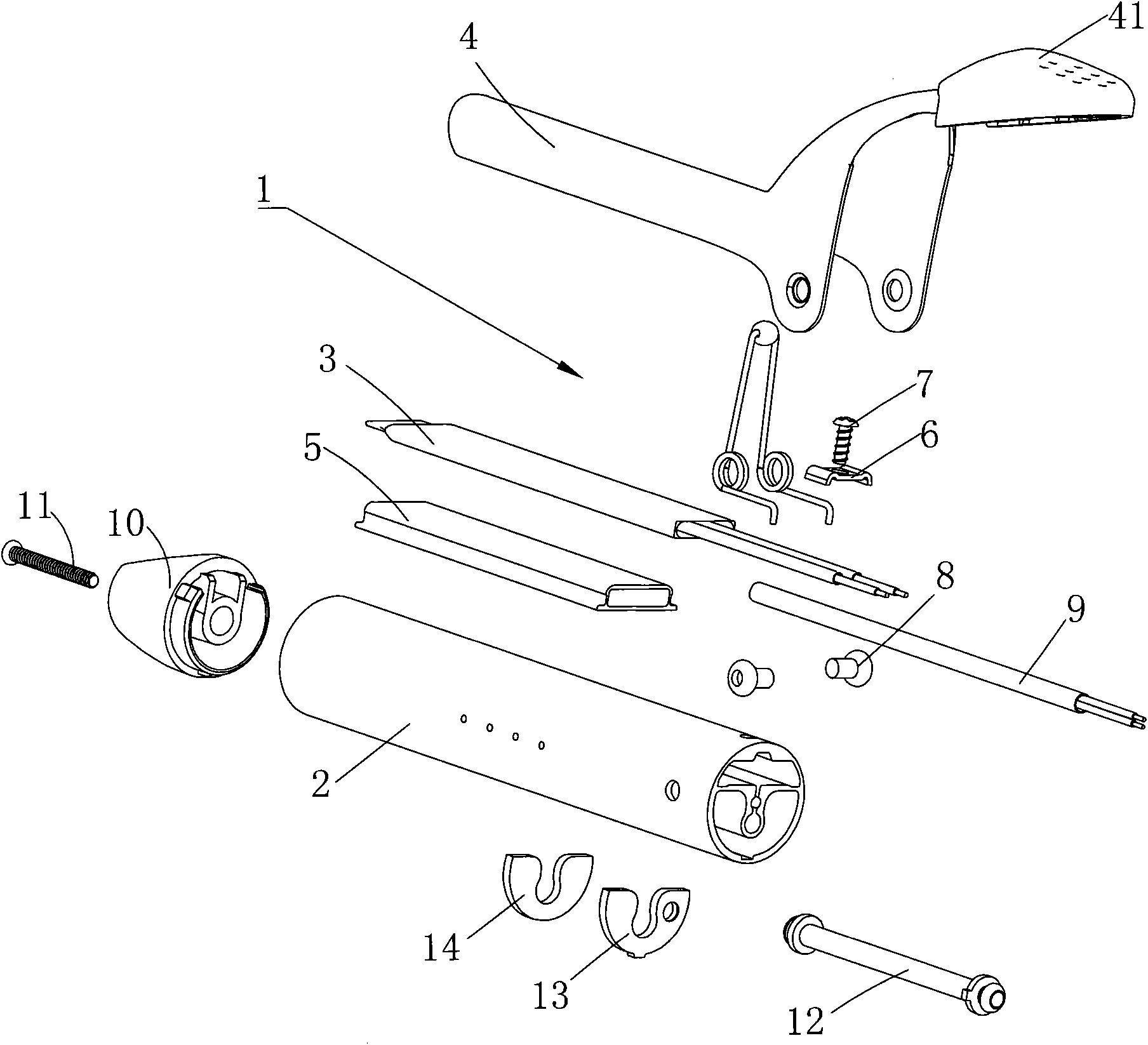

[0011] Such as Figure 1-Figure 2 As shown, it is a hair curler of the present invention, which includes an aluminum tube 2, a PTC heating element 3 is arranged inside the aluminum tube 2, and a hairpin 4 is elastically and movably connected to the aluminum tube 3. The hairpin 4 is connected to the aluminum tube 2 through the torsion spring 5, the torsion spring pressure plate 6, the screw 7 and the cone head 8. There is a button 41 on the hairpin 4. When you need to use the hairpin, you only need to press the button 41 with your hands , the hairpin 4 can be opened, and when the external force disappears, the hairpin 4 resets automatically. The heating element 3 is wrapped by the aluminum plate 5, and the aluminum plate 5 constitutes a heating box, and the heating box and the aluminum tube 3 are connected by plane contact, and the heat transfer is carried out by means of the plane contact, and the efficiency is very high. When the temperature of the heating element 3 is 280 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com