Lactobacillus microcapsule and preparation method thereof

A lactic acid bacteria microcapsule and lactic acid bacteria technology, applied in the field of preservation of probiotics, can solve the problems of high production cost, high air inlet temperature, reduced product utilization rate and the like, and achieve the effects of low product cost, improved survival rate and strong stress resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

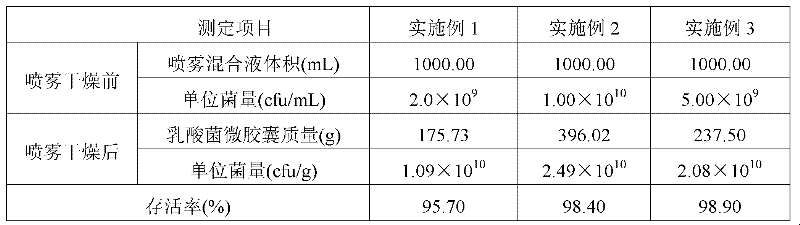

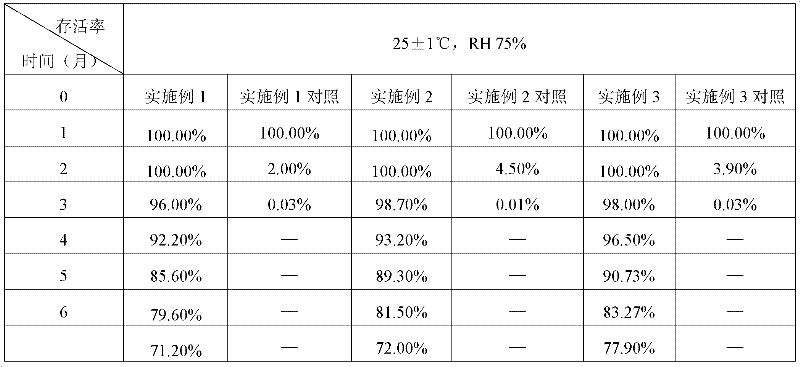

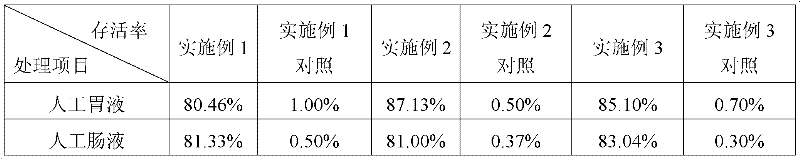

[0017] The preparation of embodiment 1 lactobacillus plantarum microcapsules

[0018] 1. Concentrated Lactobacillus plantarum fermentation liquid

[0019] Centrifuge the fermentation culture solution of Lactobacillus plantarum at 4°C and 5000r / min for 10 minutes, wash the collected bacteria twice with normal saline, and resuspend the bacteria sludge to make a bacterial suspension for later use; the medium used can be selected MRS medium or any suitable medium for lactic acid bacteria.

[0020] 2. Preparation of spray mixture

[0021] Weigh 25g of soybean protein, 100g of skim milk, 25g of maltodextrin, 25g of glucose, and 2.5g of gelatin according to the mass ratio of 1:4:1:1:0.1, add water, stir and mix, and fully mix with the above bacterial suspension, Add water to adjust the mixture to 1000mL, in which the final concentration of bacteria is 2×10 9 cfu / mL, the weight-to-volume concentration of each component of the protective wall material is: soybean protein 2.5%, skim ...

Embodiment 2

[0024] Example 2 Preparation of Lactobacillus acidophilus microcapsules

[0025] 1. Concentrated Lactobacillus acidophilus fermentation broth

[0026] 4°C, 4000r / min, 10min, centrifuge the fermentation broth of Lactobacillus acidophilus, wash twice with normal saline, resuspend the sludge, and set aside;

[0027] 2. Preparation of spray mixture

[0028] Weigh 100g of soybean protein, 150g of skimmed milk, 75g of maltodextrin, 50g of glucose, and 25g of gelatin according to the mass ratio of 4:6:3:2:1, add water and mix well, and mix well with the above bacterial suspension, add water Adjust the mixture to 1000mL, in which the final concentration of bacteria is 1.0×10 10 cfu / mL, the weight-to-volume concentration of each component of the protective wall material is: soybean protein 10.0%, skim milk 15.0%, maltodextrin 7.5%, glucose 5.0%, and gelatin 2.5%.

[0029] 3. Spray drying treatment

[0030] A centrifugal spray dryer is used for spray drying treatment. The air inlet ...

Embodiment 3

[0031] The preparation of embodiment 3 Enterococcus faecium and Lactobacillus casei mixed bacteria microcapsules

[0032] 1. Concentrated fermented broth of Enterococcus faecium and Lactobacillus casei

[0033] 4°C, 4000r / min, 15min, centrifuge the fermentation broth of Enterococcus faecium and Lactobacillus casei respectively, wash twice with normal saline, resuspend the sludge, count, and divide Enterococcus faecium at a ratio of 1:1. The suspension is mixed with the Lactobacillus casei suspension, and set aside;

[0034] 2. Preparation of spray mixture

[0035] Weigh 50g of soybean protein, 100g of skimmed milk, 50g of maltodextrin, 25g of glucose, and 15g of gelatin according to the mass ratio of 2:4:2:1:0.6, add water, stir and mix, and suspend with the above-mentioned Enterococcus faecium and Lactobacillus casei. Mix the solution thoroughly, add water to adjust the mixture to 1000mL, and the final concentration of bacteria is 5.0×10 9 cfu / mL, the weight-to-volume conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com